PCBN Inserts for Brake Disc/Drum

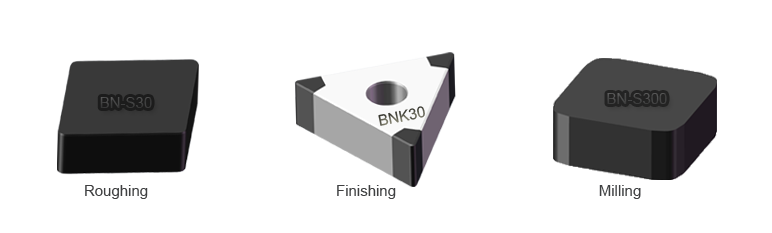

1. Halnn CBN Materials for machining Gray Cast Iron

Insert Grade | Suited Materials | Machining Type | Typical Application |

BN-S300 | Gray Cast Iron | Roughing, Finishing | Brake Disc, Cast Iron Engine,Gearbox, Cylinder Liner |

BN-S30 | Gray Cast Iron | Roughing | Brake Disc, Cast Iron Engine,Gearbox, Cylinder Liner |

BN-K20 | Gray Cast Iron | Semi-Finishing, Finishing | Brake Disc, Cast Iron Engine,Gearbox |

BNK30 | Gray cast iron, Iron based alloy | Semi-Finishing,Finishing | Brake Disc, Brake Drum, Cast Iron Engine, Gearbox |

2. The cutting condition of Halnn CBN Insert

CBN Content | Characteristics | Halnn CBN | Cutting Depth | Condition |

High Content | Toughnes(Roughing) | BN-S30 | 1-10mm | Semi-Interrupt |

BN-S300 | ≤2mm | Continuous | ||

BNK30 | ≤1.5mm | Continuous | ||

BN-K20 | ≤0.5mm | Continuous |

3. The advantages of Halnn CBN Inserts machining gray cast iron part

(1) Improve Efficiency: Compared with coating carbide insert, it can realize high speed machining,and the suitable linear speed will be: 250~450m/min for roughing process, 450~800m/min for finishing process. And it also be suitable for the high speed milling with 1500m/min or above. The efficiency will be about 2 times more than cabide insert.

(2) Improve Tools Durability: The tool life of Halnn CBN Insert is about 15 times of carbide insert.

(3) Improve Roughness: Halnn BN-K20 and BN-S30 can receive the roughness within Ra1.6, is much better than carbide insert.

(4) Characteristics of Halnn CBN inserts: BN-S30 and BN-S300 adopt non-metal adhesive, improved the thermal conductivity and the strength, not only extand the insert lifetime, but also improve the impact resistance. And BN-S30 can be used for roughing process, BN-S300 can be used for finishing process. BN-K20 and BNK30 belong to brazed pcbn insert, both of them can be used for finishing process.

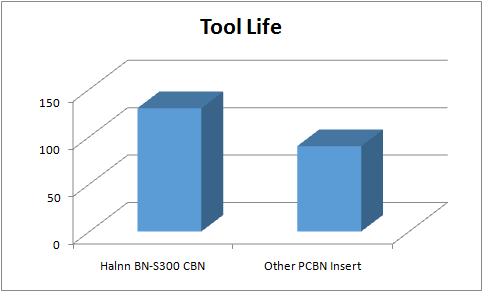

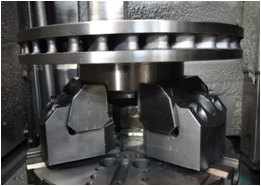

Application Case 1

| Item | Brake Disc Manufacturer | Advantages compraison |

Component Materials | GG25(HT250) |

With BN-S300 Solid cbn insert, The tool life improved 45% |

Machining Condition | Roughing,dry cutting | |

Selected Insert | BN-S300 CNGN120716 | |

| Cutting Parameters | Vc=950m/min,Fr=0.7mm/r,ap=2mm |

Application Case 2

| Item | Brake Disc Manufacturer | Image |

| Component Materials | GC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB180~HB220 | |

| Selected insert | CNGN120412 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BNK30 | Vc=1150,Fr=0.2,ap=0.25 | 640 |

Other PCBN | Vc=880,Fr=0.2,ap=0.25 | 475 |

The tool life improved 35%, and the efficiency improved about 30% ! | ||

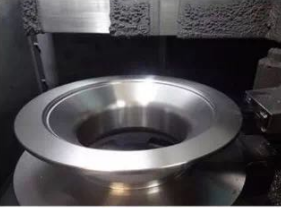

Application Case 3

| Item | Brake Disc Manufacturer | Image |

| Component Materials | GC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB210 | |

| Selected insert | BN-S300 C06 SCGN090412 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Product Image |

Halnn BN-S300 C06 | Vc=900,Fr=0.25,ap=0.3 |  |

The Tool Life of Coating CBN Inserts improved about 30%, And the roughness Keeped Ra1.6 | ||

Application Case 4

| Item | Brake Disc Manufacturer | Image |

| Component Materials | FC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB170~HB210 | |

| Selected insert | BNK30 TNGA160408-6S | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BNK30 | Vc=1000,Fr=0.2,ap=0.3 | 160 |

Other PCBN | Vc=800,Fr=0.2,ap=0.3 | 100 |

The tool life improved 60% ! | ||

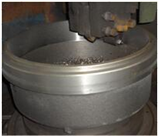

Application Case 5

| Item | Brake Drum Manufacturer | Image |

| Component Materials | FC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB170~HB210 | |

| Selected insert | WNGA080408-6S | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BNK30 | Vc=650,Fr=0.2,ap=0.5 | 120 |

Other PCBN | Vc=650,Fr=0.2,ap=0.5 | 70 |

The tool life improved 40% ! | ||

Application Case 6

| Item | Brake Drum Manufacturer | Image |

| Component Materials | FC250 (HT250) |  |

| Machining Process | Roughing, Dry Cutting | |

| Hardness | HB170~HB210 | |

| Selected insert | BN-S300 CNMN120712 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BN-S300 | Vc=500,Fr=0.55,ap=2 | 200 |

Other PCBN | Vc=180,Fr=0.2,ap=2 | 30 |

The tool life improved 1.8 Times! | ||

Application Case 7

| Item | Brake Drum Manufacturer | Image |

| Component Materials | GC250 (HT250) |  |

| Machining Process | Finishing, Dry Cutting | |

| Hardness | HB170~HB210 | |

| Selected insert | CNGN120412 | |

| Testing Performance Comparison | ||

Insert Materials | Cutting Parameters | Machining Qty |

Halnn BN-S300 | Vc=1150,Fr=0.2,ap=0.25 | 640 |

Other PCBN | Vc=880,Fr=0.2,ap=0.25 | 471=5 |

The tool life improved 35%, and the Efficiency improved about 30%! | ||