Introduction

Hard turning has emerged as a vital machining process in the production of gears, particularly in industries where precision and durability are paramount. As a leading provider of cutting tools, Halnn specializes in hard turning solutions that enhance efficiency and quality. This article explores the significance of hard turning in gear manufacturing, its advantages, and how Halnn’s products can help you achieve optimal results.

What is Hard Turning?

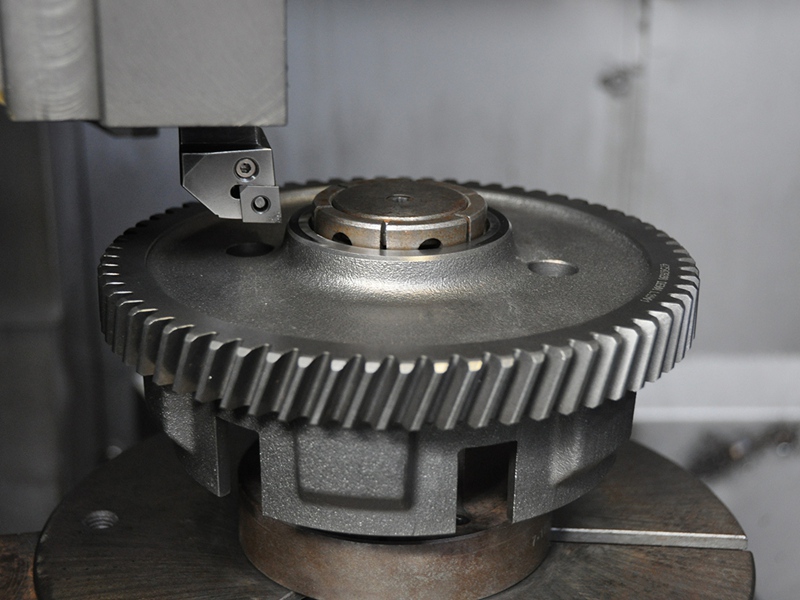

Hard turning is a machining process that involves the cutting of hardened materials, typically with a hardness of over 45 HRC (Rockwell Hardness C). This process is increasingly favored over traditional methods like grinding, as it can achieve tight tolerances and superior surface finishes in a more efficient manner. Hard turning is especially beneficial in gear production, where precision is critical.

Importance of Hard Turning in Gear Manufacturing

Hard turning offers several advantages for gear manufacturing:

Enhanced Precision: The ability to machine gears to tight tolerances ensures that they meet strict quality standards.

Improved Efficiency: Hard turning often requires fewer setups and less time compared to grinding, leading to reduced cycle times.

Versatility: This method is suitable for various gear types, including bevel gears, spur gears, and helical gears, making it an adaptable choice for manufacturers.

Key Factors Affecting Hard Turning Gear Production

Material Selection

The choice of material is crucial in hard turning. Common materials for gears include:

Hardened Steel: Widely used due to its strength and wear resistance.

Alloy Steels: Offer enhanced properties for specific applications.

Tool Steels: Provide excellent hardness and toughness.

Cutting Tools

Using the right cutting tools is essential for successful hard turning. Halnn’s CBN (Cubic Boron Nitride) inserts are specifically designed to withstand the demands of machining hardened materials. These inserts provide:

Extended Tool Life: CBN inserts are highly durable, reducing the frequency of tool changes.

Superior Performance: They maintain cutting precision even at high speeds.

Machine Settings

Optimizing machine settings is vital for effective hard turning. Key parameters include:

Cutting Speed: Proper cutting speeds are essential for balancing productivity and tool life. Higher speeds can enhance efficiency, while lower speeds may improve tool longevity.

Feed Rate: Adjusting the feed rate can help achieve the desired surface finish.

Best Practices for Hard Turning Gears

To achieve optimal results in hard turning gear production, consider the following best practices:

Adequate Cooling and Lubrication: Proper cooling helps dissipate heat and reduces friction, enhancing tool performance.

Regular Monitoring: Keep an eye on tool wear and performance, adjusting parameters as necessary to maintain quality.

Initial Trials: Conduct trials with different cutting speeds and feeds to determine the best settings for your specific gear production.

Case Studies

Halnn has successfully partnered with numerous manufacturers to enhance their gear production processes through hard turning. In one notable case, a client reported a 30% reduction in cycle time when switching from grinding to hard turning using Halnn's CBN inserts. Additionally, they achieved a superior surface finish, meeting stringent industry standards.

FAQs About Hard Turning Gear

1. What is hard turning gear?

Hard turning gear refers to the process of machining hardened gear materials, typically above 45 HRC, using cutting tools like CBN inserts. This method allows for high precision and efficiency compared to traditional grinding.

2. What are the benefits of hard turning gears?

The benefits include enhanced precision, improved surface finish, reduced cycle times, and lower production costs. Hard turning also minimizes the need for multiple setups, streamlining the manufacturing process.

3. What materials are commonly used for hard turning gears?

Common materials include hardened steel, alloy steels, and tool steels. These materials are chosen for their strength and wear resistance, essential for durable gear performance.

4. How do I determine the optimal cutting speed for hard turning gears?

Optimal cutting speeds depend on the material hardness, tool specifications, and machine capabilities. It's essential to refer to guidelines and adjust based on your specific machining conditions.

5. What cutting tools are best for hard turning gears?

CBN (Cubic Boron Nitride) inserts are ideal for hard turning gears due to their durability and ability to maintain cutting precision at high speeds. Halnn offers specialized CBN inserts designed for this application.

6. How can I improve tool life during hard turning gear operations?

Improving tool life can be achieved by optimizing cutting speeds, maintaining proper cooling and lubrication, and regularly monitoring tool wear to make necessary adjustments.

7. What challenges might I face in hard turning gear production?

Challenges can include excessive tool wear, heat generation, and achieving the desired surface finish. Addressing these requires careful monitoring of cutting parameters and using high-quality tools.

8. Is hard turning gear cost-effective compared to traditional methods?

Yes, hard turning can be more cost-effective due to reduced cycle times, less tool wear, and the elimination of grinding processes, leading to lower overall production costs.

9. Can hard turning be used for all types of gears?

Hard turning is suitable for various gear types, including spur gears, bevel gears, and helical gears, making it a versatile method for gear production.

10. How does Halnn support hard turning gear applications?

Halnn provides high-performance CBN inserts and expert guidance tailored for hard turning applications, helping manufacturers achieve optimal results in gear production.

Conclusion

Hard turning is a crucial process for efficient and precise gear manufacturing. By understanding the factors that influence hard turning speeds and applying best practices, manufacturers can significantly enhance their production capabilities. Halnn is dedicated to providing high-performance cutting tools designed specifically for hard turning applications.

For superior results in your gear production, choose Halnn as your trusted partner in hard turning solutions. Elevate your machining processes and achieve optimal quality with Halnn’s expertise and cutting-edge technology.