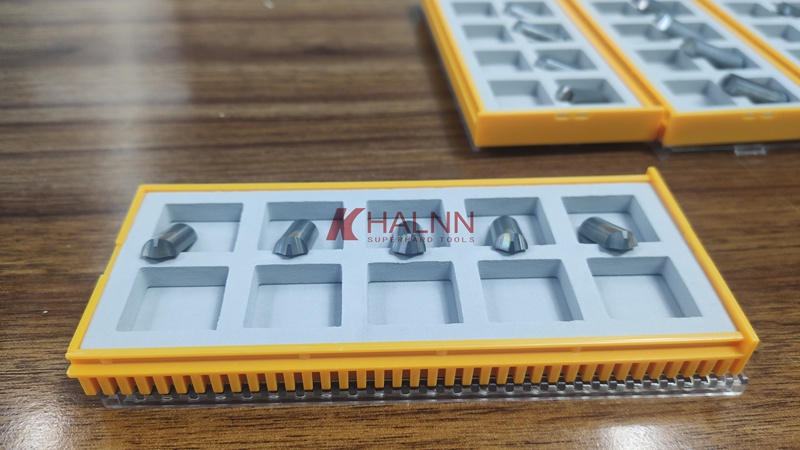

In the rolls industry, precision and durability are key when it comes to notching processes. Halnn, a leading provider of advanced tooling solutions, offers high-performance rolls carbide notching tools designed to meet the demands of challenging applications. Utilizing cutting-edge tungsten carbide materials, Halnn’s carbide rolls inserts are engineered for superior performance in both productivity and longevity. This article will explore the benefits of these tools and how they can improve efficiency in rolls manufacturing.

What Are Rolls Carbide Notching Tools?

Rolls carbide notching tools are specialized cutting tools used to create precise notches on rolls, which are essential components in various industries such as steel rolling, mining, and metal forming. The notching process requires tools that can handle high levels of stress, extreme heat, and abrasive materials. Halnn’s carbide notching tools, made from premium tungsten carbide, excel in these demanding environments, providing outstanding resistance to wear and deformation.

Key Benefits of Halnn Rolls Carbide Notching Tools:

Durability: The tungsten carbide composition ensures the tools can endure long periods of use, even under high temperature and pressure.

Precision: Halnn’s carbide rolls inserts are designed for fine-tuned, accurate notching, allowing for high-quality surface finishes.

High Resistance to Wear: Carbide’s superior hardness translates to reduced tool wear, extending tool life and reducing the frequency of tool changes.

Applications of Rolls Carbide Notching Tools

Halnn’s rolls carbide notching tools are widely used across industries for notching operations on work rolls, backup rolls, and various types of industrial rolls. The tools are particularly beneficial in the steel, mining, and metal forming industries, where precision and durability are critical.

1. Steel Industry

In steel production, rolls are exposed to intense stress and high temperatures. Halnn’s tungsten carbide rolls notching tools are optimized for these extreme conditions, ensuring accurate notching on hardened steel rolls while maintaining tool integrity over time.

2. Mining Industry

Mining operations often require custom notches on heavy-duty rolls to withstand the tough, abrasive materials they process. Carbide rolls inserts from Halnn provide the durability and wear resistance necessary for long-lasting performance in these environments.

3. Metal Forming

For metal forming processes, such as sheet metal rolling, Halnn’s rolls carbide notching tools enable precision in notching, ensuring that metal products maintain consistent quality throughout production.

Why Choose Tungsten Carbide Rolls Notching Tools?

Tungsten carbide is renowned for its hardness and resistance to wear, making it an ideal material for rolls notching tools. Compared to traditional steel tools, carbide notching tools offer several advantages, including:

Increased Tool Life: Tungsten carbide rolls notching tools can last up to 10 times longer than steel tools, which reduces tooling costs and increases uptime.

Higher Cutting Speeds: Carbide can withstand higher cutting speeds without compromising the quality of the cut, improving overall production efficiency.

Enhanced Surface Finish: The toughness of carbide allows for smoother cuts, resulting in a superior surface finish on rolls, minimizing post-machining operations.

Halnn: Your Trusted Partner in Rolls Notching Solutions

At Halnn, we specialize in providing advanced tooling solutions for the rolls industry. Our rolls carbide notching tools are designed with the needs of our clients in mind, ensuring high performance in even the most demanding applications. Whether you're in steel production, mining, or metal forming, Halnn's tungsten carbide rolls notching tools offer the durability, precision, and efficiency needed to meet modern manufacturing standards.

Why Choose Halnn Rolls Carbide Notching Tools?

Expertise in Hard Materials: With years of experience in producing tools for hard materials, Halnn is a trusted name in carbide tooling solutions.

Customized Solutions: Halnn provides customized carbide rolls inserts tailored to the specific needs of your operation, ensuring you get the best tool for your application.

Technical Support: Our team of experts is always available to provide technical support, from tool selection to optimization of machining processes.

FAQs About Rolls Carbide Notching Tools

1. What are rolls carbide notching tools used for?

Rolls carbide notching tools are designed for creating precise notches on industrial rolls, which are used in sectors like steel manufacturing, mining, and metal forming. These tools provide high durability, wear resistance, and precision during the notching process, ensuring that the rolls meet specific industry requirements.

2. Why is tungsten carbide used in rolls notching tools?

Tungsten carbide is extremely hard and wear-resistant, making it ideal for applications that involve high heat, stress, and abrasive materials. In rolls notching, this ensures longer tool life, improved cutting performance, and reduced maintenance costs compared to traditional steel tools.

3. What are the advantages of using Halnn's rolls carbide notching tools?

Halnn's rolls carbide notching tools offer multiple advantages, including:

Superior wear resistance for extended tool life

High precision in notching for smoother surface finishes

Better performance in high-speed and high-temperature operations

Lower overall tooling costs due to reduced tool changes

4. How do carbide rolls inserts differ from other notching tools?

Carbide rolls inserts, such as those offered by Halnn, are made from harder materials than traditional notching tools like steel. This gives them greater durability and wear resistance, making them ideal for notching hardened rolls used in tough environments like steel and mining industries. They also allow for higher precision and cutting speeds.

5. Can rolls carbide notching tools handle high-volume production?

Yes, rolls carbide notching tools are specifically designed for high-volume production environments. The hardness and durability of tungsten carbide enable these tools to withstand prolonged use, reducing the need for frequent tool replacements and allowing for continuous, efficient operations.

6. Are Halnn's rolls carbide notching tools suitable for different types of rolls?

Yes, Halnn offers customized carbide rolls notching tools that can be tailored to various types of rolls, including work rolls, backup rolls, and other industrial rolls. Our carbide tools are versatile and can meet the demands of multiple industries such as steel, mining, and metal forming.

7. How do I maintain rolls carbide notching tools for optimal performance?

To ensure optimal performance and longevity of your rolls carbide notching tools, regular maintenance is recommended. This includes proper cleaning, checking for wear and tear, and replacing inserts when needed. Halnn also offers technical support to help you with tool optimization.

8. What industries benefit most from using carbide rolls inserts for notching?

Industries that benefit most from using carbide rolls inserts for notching include the steel industry, mining, and metal forming. These sectors require durable, heat-resistant, and precise tooling solutions to handle the tough materials and conditions they encounter during production.

9. Can Halnn provide custom carbide notching tools for specific applications?

Yes, Halnn specializes in providing customized carbide notching tools. We work closely with clients to understand their specific needs and develop tailored tooling solutions that optimize performance and efficiency in their operations.

10. How do carbide notching tools improve overall production efficiency?

Carbide notching tools improve production efficiency by offering longer tool life, higher cutting speeds, and less downtime for tool changes. The increased precision of the tools also reduces the need for post-machining corrections, further streamlining the production process.

Conclusion

In conclusion, Halnn’s rolls carbide notching tools, including our tungsten carbide rolls notching tools and carbide rolls inserts, are the ideal solution for industries requiring durable, high-performance tools. By leveraging the hardness and precision of tungsten carbide, Halnn offers notching tools that enhance productivity, reduce costs, and improve the quality of finished products. For all your rolls notching needs, trust Halnn to deliver the tools that keep your operation running smoothly.

For more information about Halnn’s rolls carbide notching tools and other tooling solutions, visit our website or contact our technical team today.