In the world of industrial machining, selecting the right tools for the job is essential to maintaining efficiency, precision, and productivity. HSS rolls tools are cutting tools designed specifically for machining rolls made from High-Speed Steel (HSS). These rolls are commonly used in industries such as steel production, automotive, and heavy machinery due to their high durability and ability to withstand elevated temperatures and wear. This article explores the advantages and applications of HSS rolls tools, with a focus on Halnn's premium solutions tailored for tough machining tasks.

What Are HSS Rolls Tools?

HSS rolls tools are specialized cutting tools used for machining HSS rolls. These rolls, made from High-Speed Steel, possess high hardness, toughness, and resistance to wear at elevated temperatures. The unique characteristics of HSS rolls make them essential for demanding applications such as metal forming, steel rolling, and heavy machinery manufacturing.

Given the strength and wear resistance of HSS rolls, it is vital to use cutting tools that can withstand the challenges posed by these materials. Halnn's HSS rolls tools are designed to meet these challenges, providing precision, durability, and efficiency for machining high-speed steel rolls.

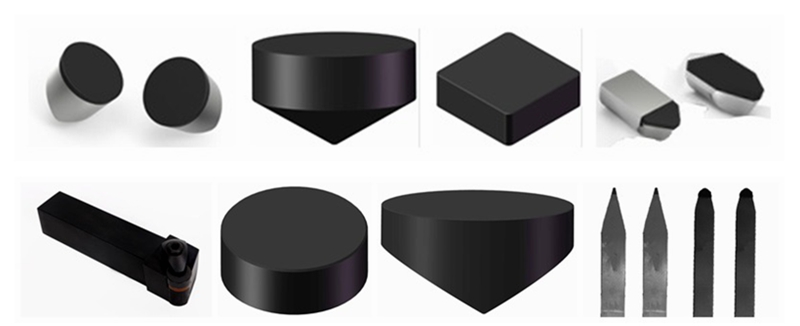

Halnn’s HSS Rolls Tools

At Halnn, our HSS rolls tools are engineered to deliver superior cutting performance and extended tool life in heavy-duty industrial applications. These tools are crafted to withstand high-speed machining while maintaining the precision required to achieve the desired surface quality on HSS rolls.

Advantages of HSS Rolls Tools

HSS rolls tools offer several advantages when machining High-Speed Steel rolls. Key benefits include:

Precision: Halnn’s HSS rolls tools are designed to maintain sharp cutting edges, allowing for precise machining of high-speed steel rolls, ensuring smooth surfaces and exact dimensions.

Durability: The toughness of HSS rolls tools allows them to resist wear and chipping, even when machining the extremely hard surfaces of HSS rolls.

High Cutting Efficiency: These tools are capable of handling the high temperatures generated during machining without losing cutting performance, making them ideal for maintaining productivity in continuous operations.

Extended Tool Life: By minimizing wear and maximizing cutting performance, Halnn’s HSS rolls tools provide longer tool life, reducing downtime and the need for frequent tool replacements.

Applications of HSS Rolls Tools

HSS rolls tools are ideal for various industrial applications where precision and durability are paramount, particularly in sectors that utilize HSS rolls for their toughness and heat resistance. Common applications include:

Steel Production: In steel rolling mills, HSS rolls tools are used to machine hardened steel rolls, ensuring a smooth surface finish and accurate dimensions.

Metal Forming: For machining rolls used in metal forming processes, HSS rolls tools offer the precision required to maintain consistency in the production of metal components.

Heavy Machinery: In industries such as forging and automotive manufacturing, where HSS rolls are commonly used, Halnn’s HSS rolls tools provide reliable machining solutions.

Halnn’s HSS Rolls Inserts: High-Performance Cutting Solutions

Halnn offers HSS rolls inserts that are designed for precision and extended tool life, even in the most challenging machining environments. Our inserts are ideal for machining high-speed steel rolls and provide:

Superior Cutting Precision: Our inserts ensure accurate cuts, delivering smooth surfaces on HSS rolls, even under demanding conditions.

Extended Tool Life: Halnn’s HSS rolls inserts are built for durability, minimizing tool wear and maximizing tool life, ensuring longer production cycles without frequent tool changes.

Customized Solutions: At Halnn, we understand that different applications have unique requirements. Our HSS rolls inserts can be customized to meet your specific machining needs.

Choosing the Right HSS Rolls Tool for Your Application

When selecting the appropriate HSS rolls tool, consider these factors:

Material Hardness: The hardness of the HSS roll being machined will influence the type of tool required. Halnn provides a range of HSS rolls tools designed for various hardness levels.

Cutting Speed: High-speed machining requires tools that maintain cutting efficiency without compromising tool life. Halnn’s HSS rolls tools are built for these conditions.

Tool Geometry: The right tool geometry, including rake and relief angles, is essential for achieving the desired surface finish. Halnn offers guidance on selecting the appropriate geometry for each application.

Continuous vs. Interrupted Cutting: Some operations may involve interrupted cuts, which can increase stress on cutting tools. Halnn’s HSS rolls tools are engineered for both continuous and interrupted cutting scenarios.

Maintenance and Best Practices for HSS Rolls Tools

To ensure maximum performance and longevity of HSS rolls tools, follow these best practices:

Optimize Cutting Parameters: Properly set cutting speed, feed rate, and depth of cut to reduce tool wear and maximize efficiency. Halnn provides recommendations for optimal parameters.

Regular Tool Inspection: Periodically check the cutting edges of the tools for wear, and replace or recondition them as necessary to maintain performance.

Use Coolant: Applying the correct coolant can help manage heat buildup during machining, prolonging tool life and improving surface finish quality.

Why Choose Halnn for HSS Rolls Tools?

Halnn is a leader in providing high-performance solutions for rolls machining. Our HSS rolls tools and inserts are specifically designed to meet the toughest machining challenges, offering superior precision, reliability, and cost-effectiveness.

Reasons to choose Halnn include:

Industry Expertise: With years of experience in the cutting tool industry, Halnn is a trusted partner for companies around the world.

Innovative Product Development: We continuously invest in research and development to ensure that our tools remain at the forefront of cutting technology.

Customer Support: From tool selection to after-sales service, Halnn offers comprehensive support to ensure your machining operations run smoothly.

For more information about Halnn’s HSS rolls tools or to inquire about customized solutions, contact us today.