Introduction

In the world of precision drilling, the carbide indexable gun drill is a game-changer, offering unparalleled accuracy, efficiency, and durability. Halnn, a leader in the industry, provides high-quality carbide indexable gun drills that cater to a wide range of industries, including aerospace, automotive, medical, and oil and gas. This comprehensive guide will explore the benefits, applications, and unique features of Halnn's carbide indexable gun drills, providing valuable insights to help you make informed decisions for your machining needs.

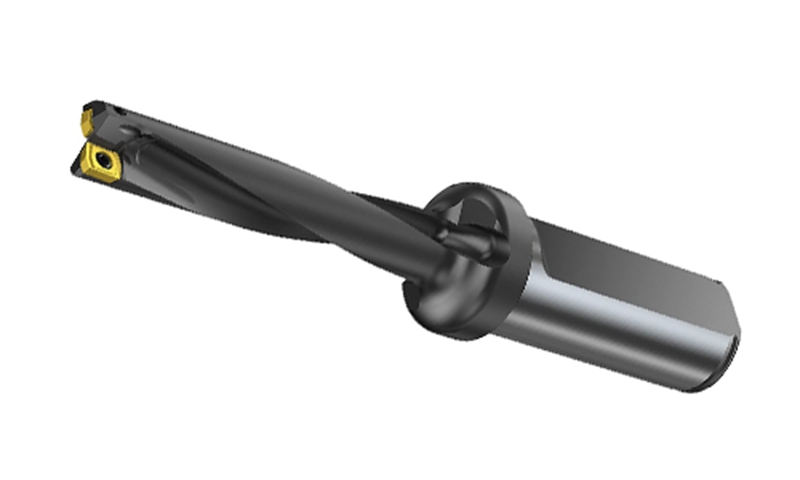

What is a Carbide Indexable Gun Drill?

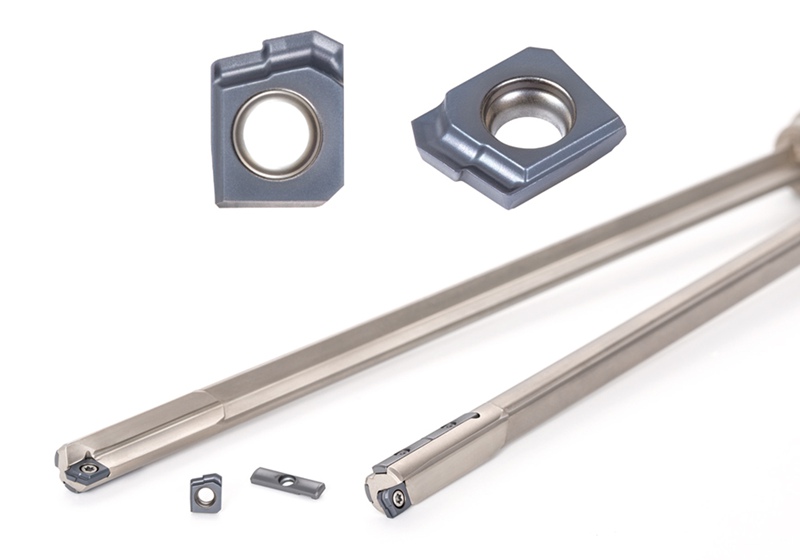

A carbide indexable gun drill is a specialized tool used for deep hole drilling with exceptional precision. Unlike traditional gun drills, which have a solid body, indexable gun drills use replaceable carbide inserts. This design allows for efficient cutting and easy maintenance, making them a cost-effective solution for various drilling applications.

Key Components

1. Carbide Inserts: The cutting edge of the drill, made from durable carbide material, ensuring precise and efficient drilling.

2. Drill Body: The main structure that holds the carbide inserts and provides stability during operation.

3. Coolant Channels: Integrated channels that deliver coolant directly to the cutting area, reducing heat and enhancing tool life.

Advantages of Carbide Indexable Gun Drills

Precision and Accuracy

Carbide indexable gun drills offer unmatched precision and accuracy in drilling operations. The carbide inserts maintain a sharp cutting edge, ensuring clean and accurate holes with minimal deviation.

Cost-Efficiency

The use of replaceable carbide inserts significantly reduces the cost of tool maintenance. Instead of replacing the entire drill, users can simply replace the worn-out inserts, leading to cost savings over time.

Versatility

Carbide indexable gun drills are versatile tools that can handle various materials, including steel, aluminum, titanium, and composites. This versatility makes them suitable for a wide range of applications across different industries.

Durability and Tool Life

Carbide, known for its hardness and resistance to wear, enhances the durability and tool life of indexable gun drills. This results in longer intervals between maintenance and tool replacements, maximizing productivity.

Maintenance and Downtime Reduction

The design of carbide indexable gun drills allows for quick and easy replacement of inserts, minimizing downtime and maintaining consistent production schedules.

Halnn’s Carbide Indexable Gun Drill Tools

Product Range and Specifications

Halnn offers a comprehensive range of carbide indexable gun drills designed to meet the diverse needs of our clients. Our product line includes various sizes and configurations, ensuring the right tool for any application. Each drill is meticulously crafted to deliver optimal performance, with specifications tailored to the specific requirements of the industry.

Customization Options

At Halnn, we understand that each project has unique requirements. That’s why we offer customization options for our carbide indexable gun drills. Whether you need a specific size, length, or coating, our team of experts will work with you to develop a solution that meets your exact needs.

Quality Assurance and Standards

Quality is at the core of everything we do at Halnn. Our carbide indexable gun drills undergo rigorous testing and quality control processes to ensure they meet the highest industry standards. We are committed to providing our clients with reliable, high-quality tools that deliver exceptional results.

Applications of Carbide Indexable Gun Drills

Aerospace Industry

In the aerospace industry, precision and reliability are paramount. Halnn’s carbide indexable gun drills are used to manufacture critical components such as engine parts, landing gear, and structural elements. Their ability to create deep, accurate holes in tough materials like titanium and Inconel makes them an essential tool for aerospace manufacturers.

Automotive Industry

The automotive sector benefits from the use of carbide indexable gun drills in the production of engine blocks, transmission components, and suspension systems. These drills enable manufacturers to achieve tight tolerances and high-quality finishes, ensuring the optimal performance of their vehicles.

Medical Devices

In the medical device industry, carbide indexable gun drills are used to create intricate parts for surgical instruments, implants, and diagnostic equipment. The precision and accuracy of these drills are crucial in ensuring the safety and efficacy of medical devices.

Oil and Gas Exploration

Carbide indexable gun drills are also employed in the oil and gas industry for drilling operations in harsh environments. Their durability and resistance to wear make them suitable for creating deep holes in challenging materials, such as rock and hardened steel.

How to Choose the Right Carbide Indexable Gun Drill

Material Considerations

When selecting a carbide indexable gun drill, it’s essential to consider the material you will be drilling. Different materials have varying properties, such as hardness and ductility, which can impact the performance of the drill. At Halnn, our experts can guide you in choosing the right drill for your specific application, ensuring optimal results and efficiency.

Drill Size and Length

The size and length of the drill are also critical factors to consider. A drill that is too long or too short can affect the accuracy and stability of the drilling process. Our team at Halnn can help you determine the appropriate size and length based on your project requirements and the specifications of your drilling machine.

Coating and Surface Treatments

Coatings and surface treatments can enhance the performance of carbide indexable gun drills by reducing friction, improving wear resistance, and extending the tool’s lifespan. At Halnn, we offer a range of coatings and surface treatments to suit different applications and materials.

Maintenance and Care for Carbide Indexable Gun Drills

Regular Inspection and Cleaning

To ensure the longevity and performance of your carbide indexable gun drills, it’s essential to conduct regular inspections and cleaning. This helps prevent buildup and wear, allowing the drill to maintain its cutting edge and efficiency.

Proper Usage and Handling

Proper usage and handling of carbide indexable gun drills are crucial to prevent damage and ensure optimal performance. At Halnn, we provide our clients with detailed guidelines and training on how to use and handle our drills safely and effectively.

Re-sharpening and Insert Replacement

Over time, even the most durable drills may require re-sharpening or insert replacement. At Halnn, we offer professional re-sharpening and insert replacement services to restore your carbide indexable gun drills to their original condition, extending their lifespan and reducing costs.

Common Challenges and Solutions

Challenge: Chip Evacuation Issues

Solution: Halnn’s carbide indexable gun drills are designed with efficient chip evacuation systems to prevent clogging and ensure smooth drilling operations.

Challenge: Heat Generation

Solution: Our drills feature advanced coolant channels that deliver coolant directly to the cutting area, reducing heat and preventing tool wear.

Challenge: Tool Wear and Breakage

Solution: Regular maintenance, proper usage, and timely replacement of inserts can significantly reduce the risk of tool wear and breakage.

FAQs About Carbide Indexable Gun Drills

Q1: What materials can be drilled with carbide indexable gun drills?

A: Carbide indexable gun drills can be used to drill a wide range of materials, including steel, aluminum, titanium, composites, and more.

Q2: How do I know if a drill is wearing out?

Q3: What is the maximum depth these drills can achieve?

Q4: Can these drills be used with any type of drilling machine?

A: Carbide indexable gun drills are compatible with various types of drilling machines, including gun drill machines, CNC machining centers, and modified lathes.

Conclusion

Carbide indexable gun drills are a valuable tool for achieving precision, efficiency, and durability in drilling applications across various industries. Halnn is committed to providing high-quality carbide indexable gun drills that meet the unique needs of our clients. With our extensive product range, customization options, and commitment to quality, we are the ideal partner for all your drilling needs.

Call to Action

Ready to enhance your drilling operations with the best carbide indexable gun drills on the market? Contact Halnn today to explore our product range and find the perfect solution for your needs. Visit our website or call our team for a consultation and take the first step towards achieving superior drilling performance.