Introduction

In the world of precision machining, achieving accurate and efficient deep hole drilling is paramount. The “gun drill” represents an advanced and efficient technology in this field, capable of producing high-precision holes with exceptional straightness and surface finish. Halnn, a leading name in the machining industry, offers top-of-the-line gun drills that cater to a wide range of applications, from automotive to aerospace industries. This article will delve into the intricacies of gun drills, covering their types, benefits, applications, and how Halnn's expertise sets our products apart.

What is a Gun Drill?

A gun drill, also known as a deep hole drill, is a specialized tool designed for high-precision drilling, capable of producing deep holes with a diameter-to-length ratio of up to 1:250. The gun drill consists of three main components: the drill head, drill shaft, and drill shank, all of which are brazed together. The tool is characterized by a V-shaped flute for external chip evacuation, a critical feature that ensures the efficient removal of chips during deep hole drilling.

Key Features of Gun Drills:

High Precision: Achieves a tolerance level of IT6-8 with excellent straightness and surface roughness.

Versatility: Suitable for both deep and shallow hole drilling in various materials such as cast iron, carbon steel, aluminum alloys, and more.

Efficiency: Completes drilling, boring, and reaming in a single pass, significantly reducing machining time.

Types of Gun Drills

Gun drills are available in various designs, each optimized for specific applications. Halnn offers a comprehensive range of gun drills, including indexable, carbide, brazed, and solid carbide gun drills, each with distinct advantages.

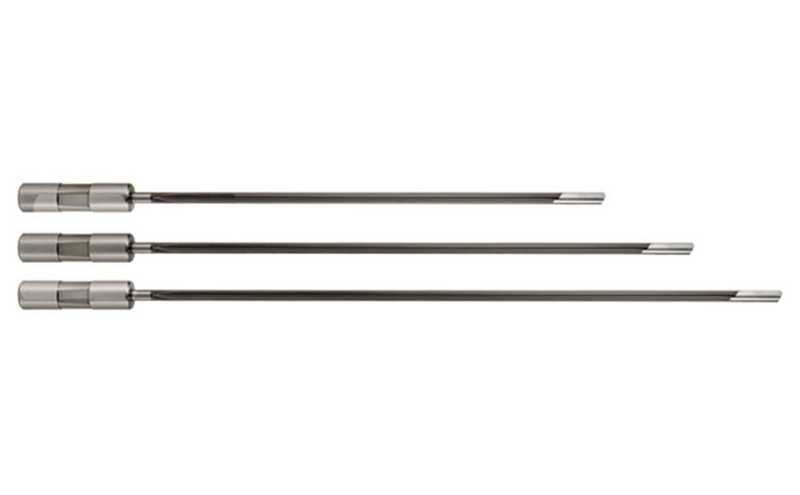

1. Indexable Gun Drill

Structure: Features a modular design with replaceable carbide inserts and guide pads.

Advantages: Ideal for large-diameter holes (above 12mm), the indexable gun drill allows for quick insert changes, minimizing downtime. The indexable design enhances cutting efficiency, making it suitable for high-speed machining.

Applications: Used in automotive, aerospace, and heavy machinery industries.

2. Carbide Gun Drill

Structure: Composed of a carbide drill head brazed to a steel shank.

Advantages: Carbide gun drills are the most common, offering a balance between cost and performance. They are known for their durability and are suitable for a wide range of materials.

Applications: Ideal for general-purpose deep hole drilling in materials like cast iron, aluminum, and steel.

3. Brazed Gun Drill

Structure: The carbide tip is brazed to a steel shank, with the entire assembly forming a single unit.

Advantages: Cost-effective and reliable, brazed gun drills are particularly useful for small to medium-diameter holes. They offer good stability and are relatively easy to maintain.

Applications: Commonly used in the manufacturing of hydraulic components, automotive parts, and other precision components.

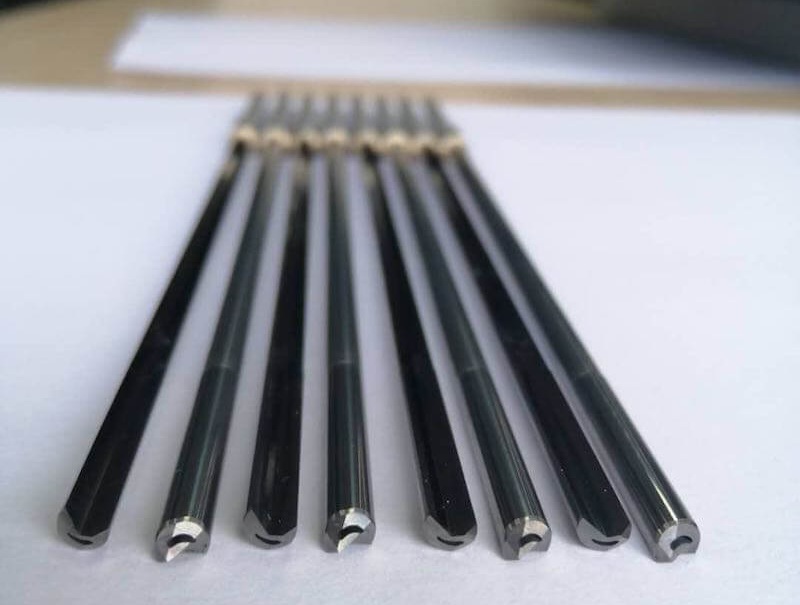

4. Solid Carbide Gun Drill

Structure: Made entirely of solid carbide, including both the drill head and shaft.

Advantages: Offers superior rigidity and reduced vibration, resulting in higher cutting reliability and extended tool life. Solid carbide gun drills are especially effective in high-strength materials and applications requiring ultra-precision.

Applications: Best suited for high-precision applications such as medical device manufacturing, aerospace, and high-performance automotive components.

Benefits of Using Gun Drills

Gun drills offer numerous advantages over conventional drilling methods, particularly in deep hole drilling scenarios. Here’s why Halnn’s gun drills stand out:

1. Precision and Accuracy

2. Efficient Chip Evacuation

3. Extended Tool Life

4. Versatility

Applications of Gun Drills

Gun drills are indispensable in industries where deep hole drilling is required. Halnn’s gun drills are used in a variety of applications, including:

1. Automotive Industry

Manufacturing of engine components, such as crankshafts, camshafts, and fuel injectors, where deep and precise holes are essential.

2. Aerospace Industry

3. Medical Device Manufacturing

4. Defense and Firearms

Factors Affecting Gun Drill Performance

Optimizing gun drill performance involves careful consideration of several factors. Understanding these elements will help you achieve the best results with Halnn’s gun drills:

1. Cutting Speed and Feed Rate

2. Coolant System

3. Tool Geometry

Maintenance and Care of Gun Drills

To maximize the lifespan of your gun drills, proper maintenance and care are essential. Here are some tips from Halnn:

1. Regular Inspection and Sharpening

2. Proper Storage

3. Troubleshooting Common Issues

How to Choose the Right Gun Drill

Selecting the appropriate gun drill depends on several factors, including the material being drilled, the desired hole depth, and the precision required. Halnn’s team of experts can assist you in choosing the right tool for your needs.

Considerations:

Material: Choose a drill with the appropriate carbide grade and coating for the material.

Diameter and Length: Ensure the drill’s diameter-to-length ratio is suitable for the application.

Coolant Requirements: Match the drill with the correct coolant system for efficient operation.

Halnn’s Gun Drill Solutions

Halnn takes pride in offering high-quality gun drills that meet the demands of modern machining. Our products are designed with precision, durability, and performance in mind, ensuring that you get the best results in every application.

Why Choose Halnn?

Expertise: With years of experience in the industry, Halnn is a trusted name in gun drill manufacturing.

Innovation: We continually innovate to provide tools that meet the evolving needs of our customers.

Customer Support: Our team is always ready to provide guidance and support, from tool selection to troubleshooting.

FAQs About Gun Drills

1. What is a Gun Drill?

A gun drill is a specialized cutting tool used primarily for deep hole drilling with a high length-to-diameter ratio. It consists of a long, slender drill with a single straight cutting edge, designed to produce precision holes with excellent surface finish and accuracy. Gun drills are commonly used in industries like automotive, aerospace, and oil and gas for drilling deep holes in materials such as steel, aluminum, and cast iron.

2. What Are the Different Types of Gun Drills?

Gun drills come in various types, including:

Brazed Gun Drills: These are the most common type, featuring a carbide tip brazed onto a steel shank.

Solid Carbide Gun Drills: Entirely made of carbide, these drills offer higher rigidity and longer tool life, especially suitable for high-performance applications.

Indexable Gun Drills: These use replaceable carbide inserts, which allow for quick tool changes and reduced downtime.

Carbide-Tipped Gun Drills: These drills combine a steel body with a carbide tip, offering a balance between cost and performance.

3. What Materials Can Be Drilled Using a Gun Drill?

Gun drills are versatile and can be used on a wide range of materials, including:

The choice of gun drill type and cutting parameters will depend on the specific material being drilled.

4. How Does a Gun Drill Work?

A gun drill operates by forcing coolant through its internal channel to the cutting edge, where it cools and lubricates the tool while also evacuating chips through a V-shaped groove along the drill body. This design ensures efficient chip removal and prevents tool breakage, allowing for the drilling of deep, precise holes with minimal deviation.

5. What Are the Key Benefits of Using a Gun Drill?

The primary benefits of using a gun drill include:

Precision: Gun drills produce highly accurate holes with excellent straightness and minimal deviation.

Surface Finish: They deliver superior surface finishes, often eliminating the need for further reaming or honing.

Efficiency: High drilling speeds and efficient chip removal enable fast, deep hole drilling.

Tool Life: Quality gun drills, especially those made from solid carbide, offer long tool life, reducing the need for frequent replacements.

6. How Do I Choose the Right Gun Drill for My Application?

Choosing the right gun drill depends on several factors, including:

Material: The material being drilled will determine whether you need a brazed, solid carbide, or indexable gun drill.

Hole Depth: For very deep holes, solid carbide or indexable gun drills may be preferred due to their rigidity and durability.

Hole Diameter: Smaller diameter holes are typically drilled with brazed or solid carbide gun drills, while larger diameters might be better suited to indexable designs.

Cost: Brazed gun drills are generally less expensive, while solid carbide and indexable types offer longer life and performance but at a higher cost.

7. Can Gun Drills Be Re-sharpened?

Yes, gun drills, particularly those made from solid carbide, can be re-sharpened multiple times. Proper re-sharpening requires specialized equipment and techniques to maintain the correct geometry and cutting edge. Regular re-sharpening extends the tool life and maintains performance, making it a cost-effective option for many users.

8. What Are the Common Issues Encountered with Gun Drilling?

Some common issues in gun drilling include:

Poor chip evacuation: This can lead to tool breakage or hole deviation. It’s often caused by inadequate coolant flow or incorrect cutting parameters.

Tool wear: Excessive wear can result from drilling hard materials, using incorrect cutting speeds, or insufficient lubrication.

Hole deviation: This occurs if the workpiece is not properly clamped or if the drill is not aligned correctly. It can also result from tool wear or improper setup.

9. What Coolants Should Be Used with Gun Drills?

The choice of coolant is crucial for successful gun drilling. High-pressure oil-based coolants are typically used, as they provide superior lubrication and cooling. Coolants with extreme pressure (EP) additives are recommended to reduce tool wear and improve chip evacuation, especially when drilling tough materials like stainless steel or high-temperature alloys.

10. How Does Gun Drilling Compare to Other Deep Hole Drilling Methods?

Gun drilling is often preferred over other deep hole drilling methods like twist drilling or boring due to its ability to produce highly accurate, deep holes with superior surface finish. While other methods might be faster for shorter depths or larger diameters, gun drilling excels in applications requiring long, straight holes with tight tolerances.

11. What Are the Maintenance Requirements for Gun Drills?

To maintain gun drill performance, regular inspection and maintenance are essential:

Check for wear and damage: Regularly inspect the drill for signs of wear or damage, especially at the cutting edges.

Re-sharpening: Timely re-sharpening of the tool can extend its life and maintain drilling performance.

Coolant management: Ensure that the coolant system is functioning correctly, with clean and appropriately pressurized coolant being delivered to the drill.

By following these maintenance practices, you can ensure the longevity and performance of your gun drills.

12. Where Can I Purchase High-Quality Gun Drills?

Halnn is a trusted supplier of high-quality gun drills, offering a range of options including brazed, solid carbide, and indexable gun drills. Our products are designed for durability, precision, and efficiency, ensuring optimal performance in all your deep hole drilling applications. Visit our website or contact our sales team for more information on our product offerings.

Conclusion

Gun drills are an essential tool in precision machining, offering unmatched accuracy and efficiency in deep hole drilling applications. Whether you need an indexable gun drill, carbide gun drill, brazed gun drill, or solid carbide gun drill, Halnn has the solution for you. Contact us today to learn more about our products and how we can help you achieve your machining goals.