In the intricate world of internal combustion engines, the camshaft plays a vital role in controlling valve timing and ensuring engine efficiency. As engine designs evolve to meet demands for higher performance, lower fuel consumption, and reduced emissions, the precision and efficiency of camshaft machining have become increasingly critical. This article explores the essential role of camshaft milling cutters in achieving these goals, focusing on the advanced solutions offered by Halnn, a leading provider of camshaft milling tools, inserts, and cutters.

Understanding the Importance of Camshaft Milling

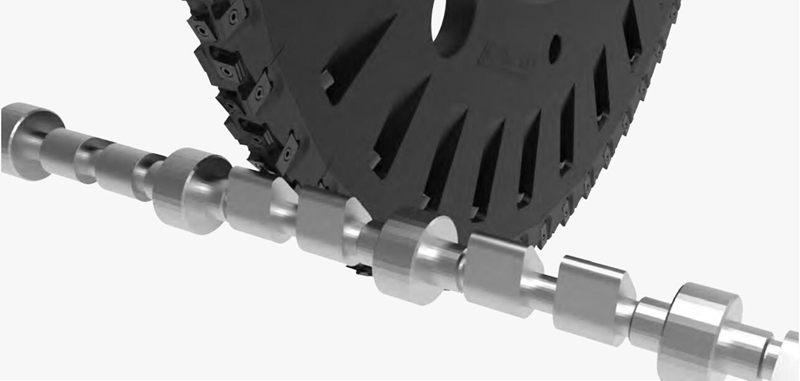

The camshaft is a crucial component in engine operation, responsible for the precise timing of valve opening and closing. This timing directly influences engine performance, fuel efficiency, and emission levels. The camshaft consists of a shaft with several lobes—one for each valve—which actuate the valves through direct contact or an intermediary mechanism.

Given the precision required in camshaft operations, the tools used for milling camshafts must meet stringent standards. This is where camshaft milling cutters come into play, providing the necessary accuracy and efficiency to manufacture camshafts that perform optimally under demanding conditions.

Types of Camshaft Milling Cutters

When it comes to camshaft milling, the choice of cutter can significantly impact the quality and cost-effectiveness of the machining process. Halnn offers a comprehensive range of camshaft milling tools designed to meet various machining requirements:

1. Solid vs. Indexable Cutters

Solid Cutters: These cutters are typically used for high-precision applications where tool rigidity and surface finish are paramount. They are ideal for specific, repetitive tasks where the same material and profile are being milled repeatedly.

Indexable Cutters: These cutters are equipped with replaceable inserts, making them highly versatile and cost-effective. Indexable camshaft milling tools are particularly useful for operations involving diverse materials or when frequent tool changes are necessary.

2. Tailored Solutions for Different Materials

Camshafts can be made from various materials, including cast iron, steel, and alloy metals. Each material presents unique challenges in milling, requiring specialized cutters to achieve the desired surface finish and dimensional accuracy. Halnn offers customized milling cutters and inserts tailored to the specific requirements of each material, ensuring optimal performance and tool life.

Key Features of Halnn’s Camshaft Milling Cutters

Halnn's camshaft milling cutters stand out in the market due to their advanced features, which are designed to enhance performance, durability, and cost-efficiency:

1. Material and Coating Technologies

Halnn uses high-performance materials such as carbide and cubic boron nitride (CBN) in their cutters, ensuring exceptional hardness and wear resistance. Additionally, advanced coatings are applied to the cutting surfaces to further enhance tool life, reduce friction, and improve heat dissipation during high-speed milling operations.

2. Optimized Cutting Geometries

The design of the cutting edge plays a crucial role in the effectiveness of the milling process. Halnn's camshaft milling tools feature optimized geometries that reduce cutting forces, minimize tool wear, and produce superior surface finishes. These geometries are particularly beneficial in high-precision operations, such as camshaft machining, where even the smallest deviations can impact engine performance.

3. Durability and Tool Life

Halnn’s camshaft milling cutters are engineered for longevity, offering extended tool life even under harsh operating conditions. This durability translates to fewer tool changes, reduced downtime, and lower overall production costs—critical factors in high-volume manufacturing environments.

4. Customization Options

Halnn recognizes that no two camshaft milling operations are identical. Therefore, they offer tailored solutions to meet the specific needs of each client. Whether it’s customizing the tool geometry, selecting the appropriate insert material, or designing a unique cutter for a specialized application, Halnn works closely with clients to deliver tools that maximize efficiency and precision.

Applications of Halnn’s Camshaft Milling Cutters

Halnn’s camshaft milling cutters are widely used across various industries, with the automotive sector being the primary beneficiary. The high precision and durability of these cutters make them ideal for manufacturing camshafts in engines designed for both commercial and high-performance vehicles. Beyond automotive, these tools are also utilized in marine, aerospace, and industrial applications where engine performance is critical.

Best Practices for Using Camshaft Milling Cutters

To achieve the best results with camshaft milling cutters, it’s essential to follow best practices in tool setup, operation, and maintenance:

1. Setup and Alignment

Proper machine setup and alignment are crucial for ensuring the accuracy and efficiency of the milling process. Misalignment can lead to uneven wear, tool breakage, and suboptimal camshaft performance.

2. Maintenance Tips

Regular maintenance of milling cutters is necessary to extend their life and ensure consistent performance. This includes routine inspection, cleaning, and proper storage of the tools when not in use.

3. Common Mistakes to Avoid

Operators should be aware of common mistakes such as incorrect feed rates, inadequate cooling, and improper tool selection, all of which can lead to premature tool wear and machining errors. Following manufacturer guidelines and receiving proper training can help avoid these issues.

Why Choose Halnn’s Camshaft Milling Cutters?

Halnn’s commitment to innovation and quality sets them apart in the competitive field of camshaft milling. Here’s why Halnn’s products are the preferred choice for manufacturers:

1. Innovation and R&D

Halnn continually invests in research and development to bring cutting-edge technologies to their milling tools. This focus on innovation ensures that Halnn’s customers always have access to the latest advancements in machining technology.

2. Customer Support and Service

Halnn provides comprehensive customer support, from the initial consultation to ongoing technical assistance. Their team of experts is dedicated to helping clients select the right tools, optimize their processes, and troubleshoot any issues that arise.

3. Global Reach and Trust

With a global presence and a reputation for excellence, Halnn has earned the trust of manufacturers worldwide. Their tools are known for their reliability, performance, and the significant value they bring to machining operations.

Conclusion

In the demanding field of camshaft production, the choice of milling tools is critical to achieving precision, efficiency, and cost-effectiveness. Halnn’s camshaft milling cutters, with their advanced materials, optimized geometries, and tailored solutions, offer manufacturers the tools they need to stay competitive in today’s market.

Whether you’re producing camshafts for high-performance automotive engines or industrial machinery, Halnn has the expertise and product range to meet your needs. Contact Halnn today to learn more about their camshaft milling tools and how they can enhance your manufacturing process.

Contact Information: