Camshaft milling is a critical process in the automotive and industrial sectors, where precision and efficiency are paramount. At Halnn, we specialize in providing top-tier milling solutions designed to meet the highest standards of quality and performance. This article delves into the intricacies of camshaft milling, exploring the tools, techniques, and innovations that drive success in this demanding field.

I. Introduction

Overview of Camshaft Milling

Camshaft milling involves the precise machining of camshafts, which are essential components in internal combustion engines. The camshaft controls the timing of the engine valves, directly impacting engine performance and efficiency.

Significance of Accurate Camshaft Milling

Achieving high precision in camshaft milling is crucial. Inaccurate milling can lead to engine inefficiencies, increased emissions, and reduced performance. Therefore, using advanced milling tools and techniques is essential for optimal results.

II. Understanding Camshaft Milling

What is Camshaft Milling?

Camshaft milling is the process of removing material from a camshaft blank to create the desired cam profile. This process involves using specialized milling tools and machines to achieve precise dimensions and surface finishes.

Materials Used in Camshaft Milling

Common materials for camshafts include cast iron, steel, and aluminum. Each material has unique properties that affect the milling process, such as hardness, machinability, and thermal stability.

III. Tools and Equipment for Camshaft Milling

Types of Milling Machines Used

Vertical and horizontal milling machines are commonly used in camshaft milling. CNC (Computer Numerical Control) milling machines are particularly advantageous due to their precision and repeatability.

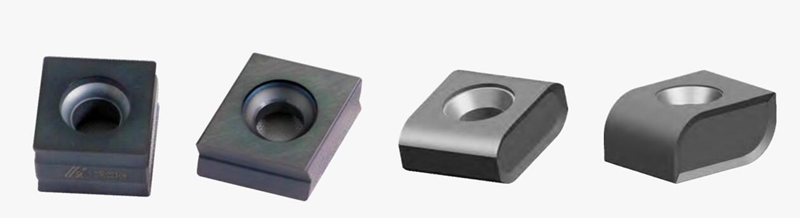

Cutting Tools for Camshaft Milling

The choice of cutting tools, including camshaft milling inserts, camshaft milling cutters, and camshaft milling tools, is critical. These tools must be durable, sharp, and capable of withstanding high temperatures and forces.

IV. Camshaft Milling Process

Steps in the Milling Process

Preparing the Camshaft Blank: The blank is inspected and prepared for milling.

Setting Up the Milling Machine: The machine is calibrated, and the camshaft blank is secured.

Performing Rough Milling: Initial material removal to shape the camshaft.

Fine Milling and Finishing Operations: Precision milling to achieve the final cam profile and surface finish.

Techniques for Precision Milling

Precision in camshaft milling is achieved through meticulous toolpath planning, advanced CNC programming, and rigorous quality control measures.

V. Challenges in Camshaft Milling

Common Milling Problems

Tool Wear and Breakage: Frequent tool wear can lead to inaccuracies.

Surface Finish Issues: Achieving a smooth surface finish is challenging.

Maintaining Tight Tolerances: Ensuring dimensions are within strict tolerances is essential.

Solutions and Best Practices

Selecting the Right Tools: Using high-quality camshaft milling inserts and cutters.

Effective Cooling and Lubrication: Reducing heat and friction during milling.

Regular Maintenance and Calibration: Ensuring machines are in optimal condition.

VI. Innovations in Camshaft Milling

Recent Technological Advancements

High-Speed Milling Techniques: Increasing productivity without compromising precision.

Adaptive Machining and Smart Manufacturing: Enhancing efficiency through automation and data analysis.

Simulation and CAD/CAM Software: Improving toolpath planning and reducing errors.

Future Trends in Camshaft Milling

Emerging technologies, such as AI and machine learning, are expected to further revolutionize camshaft milling, offering even greater precision and efficiency.

VII. Case Studies

Real-World Applications

Several automotive manufacturers have successfully implemented advanced camshaft milling techniques, resulting in improved engine performance and efficiency.

Lessons Learned

Key takeaways include the importance of using high-quality milling tools and the benefits of investing in advanced machining technology.

VIII. Conclusion

Summary of Key Points

Camshaft milling is a critical process that requires precision and advanced tools. Overcoming challenges in tool wear, surface finish, and tolerance maintenance is essential for success.

Final Thoughts

As the industry evolves, embracing new technologies and best practices will be crucial for maintaining competitiveness in camshaft milling.

IX. About Halnn

Company Overview

Halnn is a leading provider of advanced milling solutions, specializing in camshaft milling tools and technologies.

Halnn’s Products and Services

We offer a comprehensive range of milling tools, including camshaft milling inserts, cutters, and specialized machines, designed to meet the highest standards of precision and durability.

FAQs About Camshaft Milling

Q1: What is camshaft milling?

A1: Camshaft milling is the process of machining a camshaft to create the desired cam profile. This involves removing material from a camshaft blank using specialized milling tools and machines to achieve precise dimensions and surface finishes.

Q2: Why is precision important in camshaft milling?

A2: Precision in camshaft milling is crucial because it directly affects engine performance. Accurate milling ensures the camshaft controls the timing of engine valves correctly, leading to optimal engine efficiency, reduced emissions, and improved overall performance.

Q3: What materials are commonly used for camshafts?

A3: Camshafts are typically made from materials such as cast iron, steel, and aluminum. These materials are chosen for their durability, machinability, and ability to withstand the high stresses and temperatures experienced in engine operation.

Q4: What types of milling machines are used for camshaft milling?

A4: Both vertical and horizontal milling machines are used for camshaft milling. CNC (Computer Numerical Control) milling machines are particularly advantageous due to their high precision, repeatability, and ability to produce complex cam profiles efficiently.

Q5: What cutting tools are essential for camshaft milling?

A5: Essential cutting tools for camshaft milling include camshaft milling inserts, camshaft milling cutters, and specialized camshaft milling tools. These tools need to be durable, sharp, and capable of withstanding high temperatures and forces during the milling process.

Q6: What are the main steps in the camshaft milling process?

A6: The main steps include:

Preparing the camshaft blank by inspecting and preparing it for milling.

Setting up the milling machine, including calibrating the machine and securing the camshaft blank.

Performing rough milling to shape the camshaft.

Conducting fine milling and finishing operations to achieve the final cam profile and surface finish.

Q7: What are the common challenges in camshaft milling?

A7: Common challenges include tool wear and breakage, maintaining tight tolerances, and achieving a smooth surface finish. These challenges can be mitigated by using high-quality tools, effective cooling and lubrication, and regular machine maintenance.

Q8: How can tool wear be minimized during camshaft milling?

A8: Tool wear can be minimized by selecting high-quality camshaft milling inserts and cutters, ensuring effective cooling and lubrication to reduce heat and friction, and performing regular maintenance and calibration of the milling machines.

Q9: What advancements have been made in camshaft milling technology?

A9: Recent advancements include high-speed milling techniques, adaptive machining and smart manufacturing, and the use of simulation and CAD/CAM software for improved toolpath planning and error reduction. These technologies enhance productivity and precision in camshaft milling.

Q10: How does Halnn support the camshaft milling industry?

A10: Halnn provides advanced milling solutions, including high-quality camshaft milling tools and technologies. Our products are designed to meet the highest standards of precision and durability, helping manufacturers achieve superior results in their camshaft milling processes.

For more information on camshaft milling tools and solutions, visit Halnn's website or contact us directly.

Contact Information