Introduction

In the world of precision machining, minimizing vibrations and achieving superior accuracy are paramount. Damping mini precision boring tools, such as those offered by Halnn, are engineered to meet these demands. By incorporating advanced damping technology, these tools provide machinists with the ability to produce high-quality, precise bores while extending tool life and reducing operational challenges. This article will explore the benefits, applications, and selection criteria for damping mini precision boring tools, and explain why Halnn is the go-to choice for professionals in the industry.

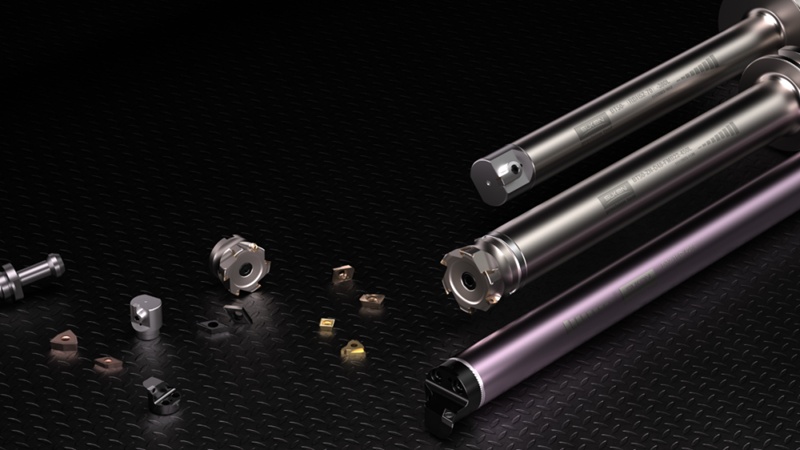

What are Damping Mini Precision Boring Tools?

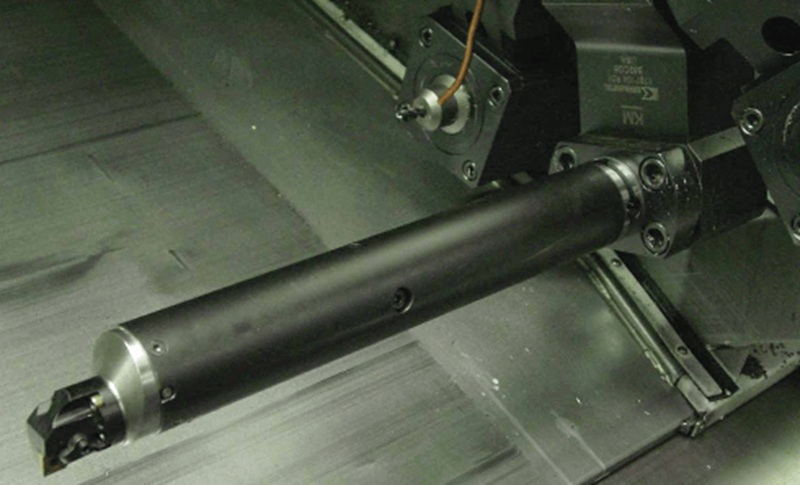

Damping mini precision boring tools are specialized cutting tools designed to reduce vibrations and enhance the precision of boring operations. These tools are essential in applications where tight tolerances and superior surface finishes are required. Unlike standard boring tools, damping mini precision boring tools incorporate advanced damping mechanisms that significantly reduce vibrations, ensuring higher accuracy and smoother finishes.

Benefits of Using Damping Mini Precision Boring Tools

Improved Machining Precision

One of the primary benefits of damping mini precision boring tools is their ability to enhance machining precision. By minimizing vibrations, these tools ensure that the cutting process is stable and controlled, resulting in accurate and consistent bores.

Enhanced Tool Life and Durability

Damping mechanisms within these tools reduce the stress and wear on the cutting edges, extending the overall life of the tool. This leads to cost savings and increased efficiency in machining operations.

Reduction in Vibrations and Chatter

Vibrations and chatter can significantly impact the quality of the machining process. Damping mini precision boring tools are specifically designed to address these issues, providing a smoother and more stable cutting experience.

Better Surface Finish and Dimensional Accuracy

The reduction in vibrations ensures that the workpiece maintains its dimensional accuracy and achieves a superior surface finish. This is crucial in industries where high-quality finishes are necessary.

How Damping Technology Works in Boring Tools

Damping technology in boring tools involves the use of materials and construction methods that absorb and dissipate vibrations. These tools often include:

Damping Elements: Materials like polymers or composites that absorb vibrations.

Tuned Mass Dampers: Additional masses within the tool that counteract vibrational energy.

Advanced Tool Construction: Design elements that enhance the rigidity and stability of the tool.

These components work together to minimize the impact of vibrations, ensuring precise and efficient machining.

Applications of Damping Mini Precision Boring Tools

Common Industries and Applications

Damping mini precision boring tools are used in a variety of industries, including aerospace, automotive, and medical device manufacturing. They are ideal for applications requiring high precision and tight tolerances.

Specific Examples

Aerospace: Ensuring the precision of critical components like turbine blades and engine parts.

Automotive: Machining engine blocks and transmission components with high accuracy.

Medical Devices: Producing intricate and precise parts for medical equipment.

Unique or Innovative Uses

In addition to traditional applications, damping mini precision boring tools are also used in innovative manufacturing processes such as additive manufacturing, where precise post-processing is essential.

Selecting the Right Damping Mini Precision Boring Tool

Choosing the right damping mini precision boring tool involves considering several factors:

Material

The material of the workpiece influences the choice of tool. Different materials require specific cutting characteristics to achieve optimal results.

Tool Size

The size of the tool should match the dimensions of the bore being machined. Selecting the appropriate size ensures stability and precision.

Precision Requirements

Depending on the application, the required level of precision will dictate the choice of tool. Higher precision tools are necessary for applications with tight tolerances.

Comparison of Models

Halnn offers a variety of damping mini precision boring tools, each designed for specific applications. Comparing models based on their features and capabilities helps in making an informed decision.

Case Studies and Customer Testimonials

Real-World Examples

Halnn's damping mini precision boring tools have been successfully used in various applications. For instance, an aerospace manufacturer reported a significant improvement in precision and surface finish after switching to Halnn's tools.

Testimonials

Satisfied customers have praised Halnn's tools for their durability and performance. A leading automotive manufacturer stated, "Halnn's damping mini precision boring tools have transformed our machining process, providing unparalleled precision and efficiency."

Maintenance and Care of Damping Mini Precision Boring Tools

Proper maintenance is essential to ensure the longevity and performance of damping mini precision boring tools. Here are some tips:

Regular Inspection

Regularly inspect the tools for signs of wear or damage. Replace any worn components to maintain performance.

Cleaning

Keep the tools clean and free from debris. Proper cleaning prevents buildup that can affect the tool's performance.

Storage

Store the tools in a dry and secure environment. Proper storage prevents damage and extends the life of the tools.

Why Choose Halnn for Damping Mini Precision Boring Tools?

Halnn is a leader in the industry, known for its high-quality damping mini precision boring tools. Here are some reasons to choose Halnn:

Expertise and Reputation

With years of experience and a strong reputation, Halnn is a trusted provider of precision machining tools.

Quality and Reliability

Halnn's tools are manufactured to the highest standards, ensuring durability and performance.

Certifications and Awards

Halnn has received numerous certifications and awards, highlighting its commitment to quality and innovation.

FAQs About Damping Mini Precision Boring Tool

1. What is a Damping Mini Precision Boring Tool?

A Damping Mini Precision Boring Tool is a specialized cutting tool designed to minimize vibrations and enhance the precision of boring operations. These tools incorporate damping mechanisms to provide stable, accurate, and high-quality machining.

2. How does a Damping Mini Precision Boring Tool work?

The tool works by integrating materials and construction techniques that absorb and dissipate vibrations during the machining process. This reduces tool chatter and ensures a more stable and precise cutting operation.

3. What are the benefits of using a Damping Mini Precision Boring Tool?

The primary benefits include improved machining precision, extended tool life, reduced vibrations and chatter, and better surface finish and dimensional accuracy of the machined parts.

4. In which industries are Damping Mini Precision Boring Tools commonly used?

These tools are widely used in industries that require high precision and tight tolerances, such as aerospace, automotive, medical device manufacturing, and more.

5. How do I choose the right Damping Mini Precision Boring Tool for my application?

Choosing the right tool involves considering the material of the workpiece, the size of the bore, and the required level of precision. It’s also important to compare different models based on their features and capabilities to match your specific machining needs.

6. Can Damping Mini Precision Boring Tools be used with various materials?

Yes, these tools are versatile and can be used with a wide range of materials, including metals, alloys, and composites. However, selecting the appropriate tool for the specific material is crucial for optimal performance.

7. What maintenance is required for Damping Mini Precision Boring Tools?

Regular inspection, cleaning, and proper storage are essential to maintain the performance and longevity of these tools. Replace any worn components and keep the tools free from debris to ensure they operate efficiently.

8. How does Halnn's Damping Mini Precision Boring Tool compare to others in the market?

Halnn’s tools are renowned for their high-quality construction, advanced damping technology, and reliability. They offer superior performance, durability, and precision compared to many other options in the market.

9. Are there any real-world examples of the effectiveness of Halnn's Damping Mini Precision Boring Tools?

Yes, Halnn’s tools have been successfully used in various applications. For example, an aerospace manufacturer experienced significant improvements in precision and surface finish after using Halnn's tools.

10. Where can I purchase Halnn's Damping Mini Precision Boring Tools?

You can purchase Halnn’s tools directly from their website or contact their sales team for more information. Halnn offers a range of high-quality tools to meet different machining needs.

Conclusion

Damping mini precision boring tools are essential for achieving high precision and superior surface finishes in machining operations. Halnn's advanced damping technology and high-quality tools make them the ideal choice for professionals in various industries. By choosing Halnn, you can ensure that your machining processes are efficient, accurate, and cost-effective. For more information or to make a purchase, visit Halnn's website or contact their sales team today.