In the world of modern machining, efficiency and precision are paramount. One tool that has revolutionized the industry is the Capto quick change tooling system. This innovative solution offers numerous benefits, from reducing changeover times to improving machining accuracy. In this article, we will delve into the details of Capto quick change tooling, its benefits, applications, and why Halnn stands as a leading provider of these essential tools.

What is Capto Quick Change Tooling?

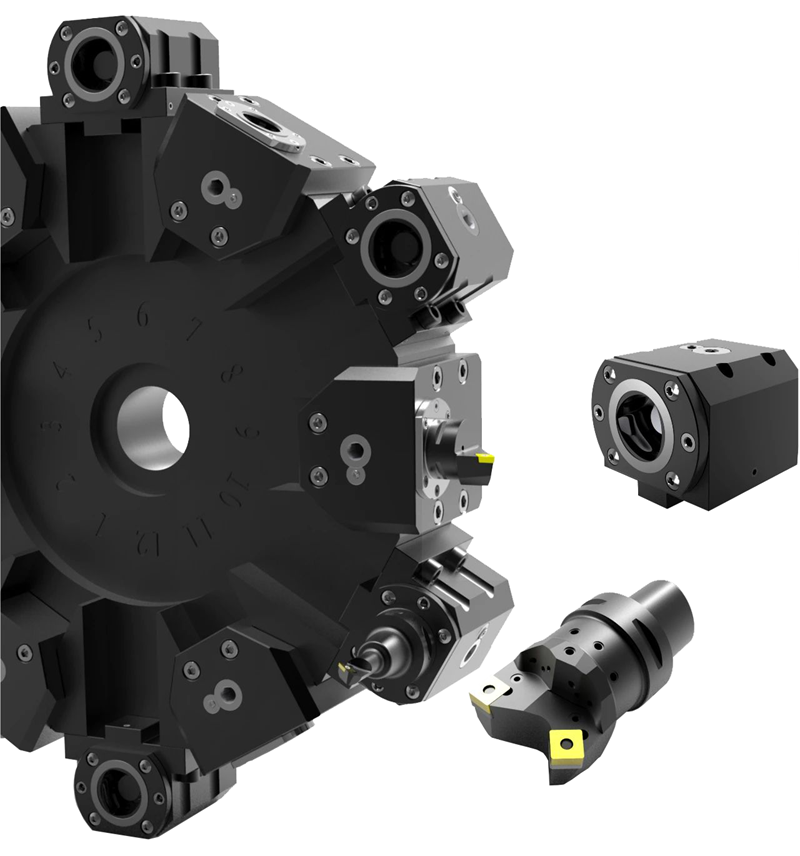

Capto quick change tooling is a modular tooling system designed to enhance the efficiency and precision of machining operations. Developed to meet the demands of modern manufacturing, Capto tooling allows for rapid tool changes without compromising on accuracy. The system comprises various components that work seamlessly together, ensuring minimal downtime and maximum productivity.

History and Development

The Capto tooling system was introduced to address the need for a more efficient and versatile tooling solution. Over the years, it has evolved, incorporating advanced materials and engineering techniques to enhance its performance. Today, Capto quick change tooling is widely recognized for its reliability and effectiveness in various machining applications.

Benefits of Capto Quick Change Tooling

Efficiency and Speed

One of the primary advantages of Capto quick change tooling is its ability to significantly reduce changeover times. Traditional tooling systems often require lengthy setup processes, leading to downtime and decreased productivity. In contrast, Capto tooling allows for quick and easy tool changes, enabling operators to switch tools in a matter of seconds. This increase in efficiency translates to higher output and reduced production costs.

Precision and Accuracy

Precision is crucial in machining, and Capto quick change tooling excels in this aspect. The system is designed to maintain high levels of accuracy during tool changes, ensuring that each component is machined to exact specifications. This precision reduces the likelihood of errors and rework, improving the overall quality of the final product.

Versatility and Flexibility

Capto quick change tooling is incredibly versatile, making it suitable for a wide range of applications across various industries. Whether it's in the automotive, aerospace, or medical sectors, Capto tooling can be easily adapted to different machining requirements. This flexibility is a significant advantage for manufacturers looking to streamline their operations and reduce the need for multiple tooling systems.

Cost-Effectiveness

Investing in Capto quick change tooling can lead to substantial cost savings in the long run. The reduction in changeover times and increased efficiency mean that machines can operate for longer periods without interruption. Additionally, the precision and accuracy of Capto tooling minimize the risk of costly errors and rework, further enhancing its cost-effectiveness.

How Capto Quick Change Tooling Works

Technical Explanation

The Capto quick change tooling system operates on a modular design, allowing various components to be easily interchanged. The system features a unique coupling mechanism that ensures a secure and precise connection between the tool holder and the machine spindle. This mechanism is designed to maintain high levels of rigidity and stability, even during high-speed machining operations.

Installation and Setup

Installing and setting up Capto quick change tooling is straightforward. The system is designed for ease of use, with intuitive interfaces and clear instructions. Operators can quickly install the tooling components, adjust the settings, and begin machining with minimal downtime. Regular maintenance and calibration ensure the system continues to perform at its best.

Applications of Capto Quick Change Tooling

Industry-Specific Uses

Capto quick change tooling is widely used in various industries due to its versatility and reliability. In the automotive industry, it is employed for precision machining of engine components and transmission parts. In aerospace, it is used for manufacturing intricate components that require high levels of accuracy. The medical sector benefits from Capto tooling's ability to produce precision instruments and implants.

Comparing Capto Quick Change Tooling with Other Systems

Advantages Over Traditional Tooling Systems

Capto quick change tooling offers several advantages over traditional tooling systems. The primary benefit is the reduction in changeover times, which leads to increased productivity. Additionally, Capto tooling's precision and accuracy are superior, reducing the risk of errors and rework.

Competitor Analysis

When compared to other quick change tooling systems, Capto stands out for its reliability and performance. While other systems may offer similar features, Capto's unique coupling mechanism and modular design provide unmatched stability and versatility.

Choosing the Right Capto Quick Change Tooling for Your Needs

Factors to Consider

When selecting Capto quick change tooling, several factors should be considered, including the specific machining requirements, material types, and desired levels of precision. It is also essential to evaluate the compatibility of the tooling system with existing machinery.

Halnn's Product Range

Halnn offers a comprehensive range of Capto quick change tooling products designed to meet various machining needs. Our products are engineered to deliver exceptional performance, precision, and reliability. Each product in our range is backed by our commitment to quality and customer satisfaction.

Maintenance and Care for Capto Quick Change Tooling

Routine Maintenance Tips

Regular maintenance is crucial to ensure the longevity and performance of Capto quick change tooling. Operators should follow recommended maintenance schedules, including cleaning, lubrication, and calibration. It is also essential to inspect the tooling components for signs of wear and replace them as needed.

Extending Tool Life

To maximize the lifespan of Capto quick change tooling, operators should adhere to best practices, such as using the correct cutting parameters and avoiding excessive loads. Proper storage and handling also play a significant role in preserving the tooling's condition.

FAQs About Capto Quick Change Tooling

What is Capto quick change tooling?

Capto quick change tooling is a modular tooling system designed to facilitate rapid tool changes in machining operations without compromising on precision or accuracy. It consists of various components that can be easily interchanged, reducing downtime and increasing productivity.

What are the main benefits of using Capto quick change tooling?

The main benefits of Capto quick change tooling include:

Reduced changeover times: Allows for quick and easy tool changes, minimizing downtime.

Increased precision and accuracy: Maintains high levels of accuracy during tool changes, reducing errors and rework.

Versatility: Suitable for a wide range of machining applications across various industries.

Cost-effectiveness: Improves overall productivity and reduces production costs over time.

How does Capto quick change tooling improve machining efficiency?

Capto quick change tooling improves machining efficiency by allowing operators to switch tools in seconds, significantly reducing changeover times. This increased efficiency translates to higher output, reduced downtime, and lower production costs.

In which industries is Capto quick change tooling commonly used?

Capto quick change tooling is used in various industries, including automotive, aerospace, medical, and general manufacturing. Its versatility and precision make it suitable for a wide range of machining applications.

How does the Capto coupling mechanism work?

The Capto coupling mechanism ensures a secure and precise connection between the tool holder and the machine spindle. This unique mechanism maintains high levels of rigidity and stability, even during high-speed machining operations, ensuring consistent accuracy.

Can Capto quick change tooling be used with existing machinery?

Yes, Capto quick change tooling is designed to be compatible with a wide range of existing machinery. However, it is essential to ensure that the specific components selected are suitable for the machine in use.

What maintenance is required for Capto quick change tooling?

Routine maintenance for Capto quick change tooling includes regular cleaning, lubrication, and calibration. It is also important to inspect the tooling components for signs of wear and replace them as needed to ensure optimal performance.

How do I choose the right Capto quick change tooling for my needs?

When selecting Capto quick change tooling, consider factors such as your specific machining requirements, the types of materials being machined, and the desired level of precision. Consulting with experts or suppliers, like Halnn, can help you choose the most suitable tooling system for your needs.

What makes Halnn's Capto quick change tooling products stand out?

Halnn’s Capto quick change tooling products are designed to deliver exceptional performance, precision, and reliability. Our products are engineered with advanced materials and techniques, ensuring high-quality results and long-term cost savings for our customers.

Where can I purchase Halnn’s Capto quick change tooling products?

You can purchase Halnn’s Capto quick change tooling products directly from our website or by contacting our sales team. We offer a comprehensive range of products to meet various machining needs and provide expert support to help you choose the right solutions.

Conclusion

In summary, Capto quick change tooling is a revolutionary solution that enhances machining efficiency and precision. With its modular design and advanced coupling mechanism, Capto tooling offers unmatched versatility and reliability. Halnn is proud to offer a comprehensive range of Capto quick change tooling products, designed to meet the diverse needs of modern manufacturing. By investing in Halnn’s Capto tooling, manufacturers can achieve higher productivity, improved product quality, and significant cost savings.

For more information about our Capto quick change tooling products, please visit our website or contact our sales team. Let Halnn help you take your machining operations to the next level.

Our website: https://www.halnncbn.com/

Email:halnntools@halnn-group.com

WhatsApp: +8615515925975