In the precision machining industry, controlling vibration and ensuring stability are crucial for achieving high-quality results. Damping anti-seismic tool bars play a vital role in this process by minimizing vibrations and enhancing the overall machining stability. In this article, we will delve into the importance of these tools, their benefits, and how Halnn, a leader in the industry, offers superior solutions.

What are Damping Anti-Seismic Tool Bars?

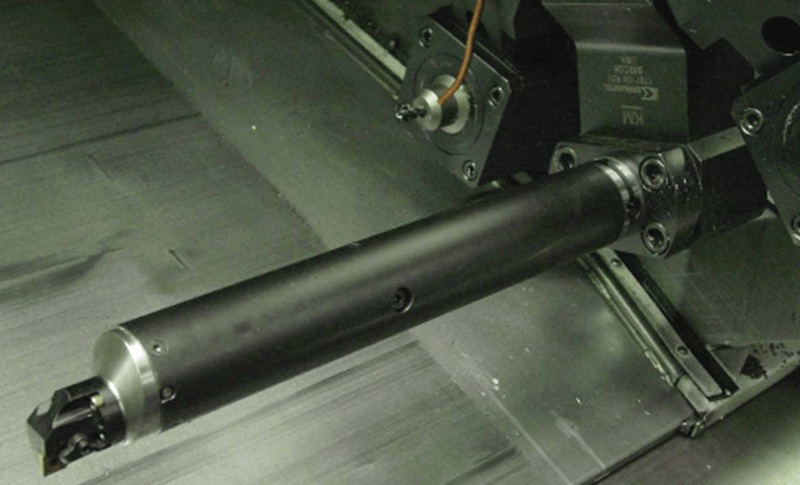

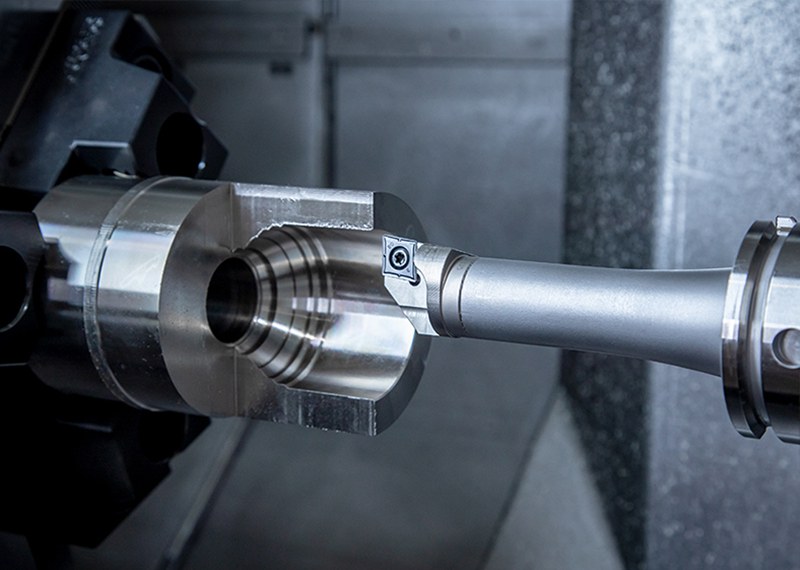

Damping anti-seismic tool bars are specialized tools designed to reduce vibrations during machining operations. These tools work by incorporating damping materials and engineering designs that absorb and dissipate vibrational energy, ensuring a more stable and precise cutting process.

Benefits of Using Damping Anti-Seismic Tool Bars

Enhanced Machining Stability: These tools minimize vibrations, leading to a more stable machining process.

Improved Surface Finish and Dimensional Accuracy: Reduced vibrations result in smoother surfaces and precise dimensions.

Increased Tool Life and Reduced Wear: Less vibration means less wear and tear on the tools, extending their lifespan.

Higher Productivity and Efficiency: With increased stability, machining can be performed at higher speeds and feeds, boosting productivity.

Noise and Vibration Reduction: These tools create a quieter and more comfortable working environment.

Key Features to Look for in Damping Anti-Seismic Tool Bars

When selecting a damping anti-seismic tool bar, consider the following features:

Material Composition: High-quality materials that offer excellent damping properties.

Design and Engineering: Advanced designs that enhance damping and stability.

Compatibility: Ensure the tool bar is compatible with your machines and applications.

Customization Options: Ability to customize the tool bar to meet specific needs.

Applications of Damping Anti-Seismic Tool Bars

These tools are beneficial in various industries, including aerospace, automotive, and heavy machinery. For instance, in the aerospace industry, precise and stable machining is crucial for producing high-quality components. Damping anti-seismic tool bars ensure the required precision and stability.

Choosing the Right Damping Anti-Seismic Tool Bar for Your Needs

When selecting a tool bar, consider factors such as the type of machine, material being machined, and the required precision. It’s essential to choose a tool bar that meets your specific needs to achieve the best results.

Halnn's Damping Anti-Seismic Tool Bars

Halnn is a trusted name in the machining industry, known for its high-quality damping anti-seismic tool bars. Our products are made from advanced materials and feature innovative designs that ensure superior performance. Whether you need tool bars for turning, milling, or boring, Halnn has the right solution for you.

Maintenance and Care Tips

To ensure the longevity and performance of your damping anti-seismic tool bars, follow these maintenance tips:

Proper Installation and Setup: Ensure the tool bar is correctly installed and set up for optimal performance.

Routine Maintenance Practices: Regularly check and maintain the tool bar to prevent issues.

Troubleshooting Common Issues: Address any issues promptly to avoid disruptions in the machining process.

Conclusion

Damping anti-seismic tool bars are essential for achieving high-quality machining results. They enhance stability, improve surface finish, increase tool life, and boost productivity. Halnn offers a range of superior damping anti-seismic tool bars designed to meet the needs of modern machining operations. Contact us today to learn more about our products and how they can benefit your operations.

FAQs About Damping Anti-Seismic Tool Bars

1. What is a damping anti-seismic tool bar?

A damping anti-seismic tool bar is a specialized machining tool designed to reduce vibrations during machining processes. These tools incorporate materials and engineering designs that absorb and dissipate vibrational energy, ensuring a more stable and precise cutting operation.

2. How do damping anti-seismic tool bars work?

These tool bars work by using damping materials and internal structures that counteract vibrations. The design helps to absorb and dissipate the energy generated during machining, minimizing the vibrations that can affect the precision and quality of the workpiece.

3. What are the benefits of using damping anti-seismic tool bars?

The benefits include enhanced machining stability, improved surface finish and dimensional accuracy, increased tool life, higher productivity and efficiency, and reduced noise and vibration in the workplace.

4. In what industries are damping anti-seismic tool bars commonly used?

These tool bars are widely used in industries that require high precision and stability in machining, such as aerospace, automotive, heavy machinery, and precision engineering.

5. How do I choose the right damping anti-seismic tool bar for my needs?

When selecting a tool bar, consider factors such as the type of machine, the material being machined, the required precision, and compatibility with existing equipment. Consulting with experts and suppliers, like Halnn, can help you make the best choice.

6. Can damping anti-seismic tool bars be customized?

Yes, many manufacturers, including Halnn, offer customization options to tailor the tool bars to specific machining requirements and applications.

7. What materials are used in the construction of damping anti-seismic tool bars?

These tool bars are typically made from advanced alloys and composites with excellent damping properties to effectively reduce vibrations.

8. How do damping anti-seismic tool bars enhance tool life?

By reducing vibrations, these tool bars decrease the wear and tear on the cutting tool, resulting in longer tool life and lower maintenance costs.

9. Are there any specific maintenance practices for damping anti-seismic tool bars?

Regular maintenance practices include proper installation and setup, routine checks for wear and tear, and prompt troubleshooting of any issues to ensure optimal performance and longevity.

10. What makes Halnn’s damping anti-seismic tool bars stand out?

Halnn’s tool bars are made from high-quality materials and feature innovative designs that ensure superior vibration damping. They are designed to meet the specific needs of modern machining operations, offering improved stability, precision, and efficiency.

11. How do these tool bars improve surface finish and dimensional accuracy?

By minimizing vibrations during machining, damping anti-seismic tool bars prevent irregularities and deviations on the workpiece surface, leading to a smoother finish and more accurate dimensions.

12. What impact do these tool bars have on productivity and efficiency?

With reduced vibrations, machining processes can be performed at higher speeds and feeds, leading to increased productivity and overall efficiency in the machining operations.

13. Can these tool bars be used in high-speed machining applications?

Yes, the enhanced stability provided by damping anti-seismic tool bars makes them suitable for high-speed machining applications, where precision and control are critical.

14. Do these tool bars reduce noise in the machining environment?

Yes, by damping vibrations, these tool bars also help to reduce noise levels, creating a quieter and more comfortable working environment.

15. How can I get more information or purchase Halnn’s damping anti-seismic tool bars?

For more information or to purchase Halnn’s high-quality damping anti-seismic tool bars, you can visit Halnn’s website or contact their sales and support team directly.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975