In the world of advanced machining, the choice of cutting tools can significantly impact the quality and efficiency of the manufacturing process. One tool that stands out for its exceptional performance and versatility is the PSC cutting tool. In this article, we will delve into the features, advantages, and applications of PSC cutting tools, with a special focus on the offerings from Halnn, a leading name in the industry.

What are PSC Cutting Tools?

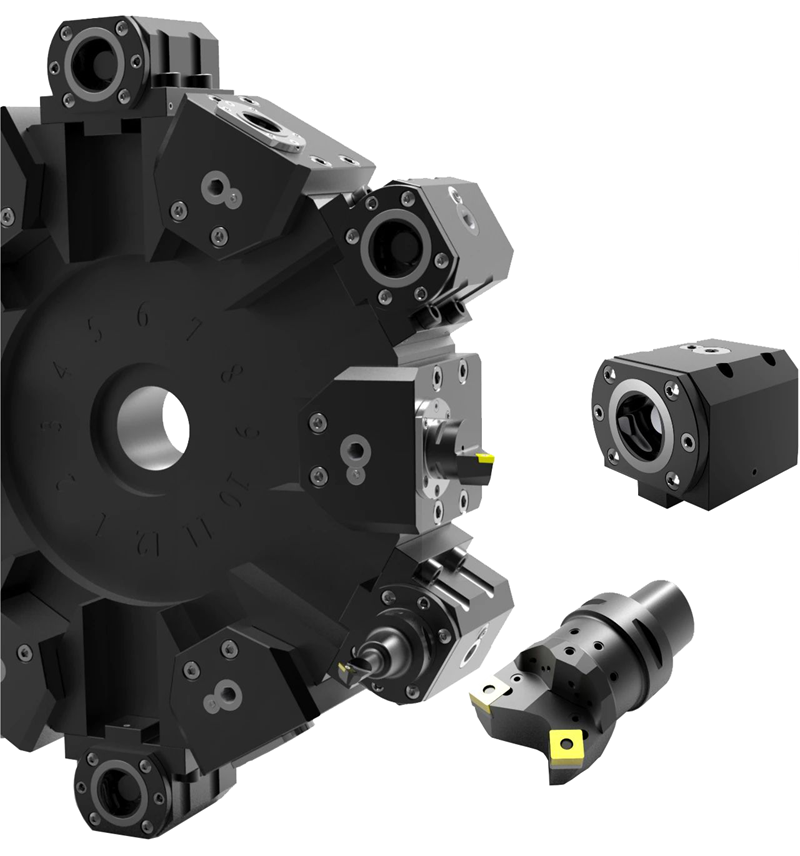

PSC, or Polygon Shank Coupling, cutting tools are designed to provide superior rigidity, precision, and quick-change capabilities. These tools are built according to the ISO 26623 standard, ensuring compatibility and reliability across various machining operations. The PSC design includes a polygonal taper interface with flange contact, which enhances tool stability and minimizes vibration during high-speed operations.

Advantages of PSC Cutting Tools

Rigidity and Stability

The polygonal taper interface of PSC cutting tools ensures a high degree of rigidity and stability. This design reduces the deflection and vibration that can occur during machining, leading to improved surface finish and prolonged tool life.

Quick-Change Capability

One of the standout features of PSC cutting tools is their quick-change capability. This allows for rapid tool changes, significantly reducing downtime and increasing overall productivity. In a matter of minutes, operators can switch tools and resume operations without compromising accuracy.

Enhanced Tool Life

The robust design of PSC cutting tools contributes to their extended tool life. The high rigidity and stability minimize wear and tear, allowing these tools to perform consistently over longer periods.

High Precision and Accuracy

PSC cutting tools are known for their high precision and accuracy. The polygonal taper interface ensures consistent and repeatable tool positioning, which is crucial for maintaining tight tolerances in high-precision machining operations.

Versatility and Customization

PSC cutting tools are versatile and can be customized to meet specific machining needs. Whether it's external turning, internal turning, or milling, PSC tools can be tailored to provide optimal performance for various applications.

Types of PSC Cutting Tools

PSC External Turning Tools

External turning tools equipped with PSC interfaces offer superior performance in turning operations. These tools are ideal for applications requiring high rigidity and precision, such as the aerospace and automotive industries.

PSC Internal Turning Tools

PSC internal turning tools are designed for machining the internal surfaces of components. They provide the same level of rigidity and precision as their external counterparts, ensuring excellent surface finishes and dimensional accuracy.

PSC Milling Tools

Milling tools with PSC interfaces combine the benefits of quick-change capability with the rigidity required for high-speed milling operations. These tools are suitable for a wide range of milling applications, from roughing to finishing.

Applications of PSC Cutting Tools

PSC cutting tools are used across various industries due to their exceptional performance and versatility. Some key applications include:

Aerospace Industry: Precision and reliability are paramount in aerospace manufacturing. PSC cutting tools ensure the high-quality machining of critical components.

Automotive Industry: The automotive industry benefits from the quick-change capability and high rigidity of PSC tools, leading to improved productivity and quality.

Medical Device Manufacturing: PSC tools provide the precision required for machining medical devices, ensuring compliance with stringent quality standards.

General Engineering: PSC cutting tools are versatile enough to be used in a wide range of general engineering applications, offering reliability and efficiency.

Halnn's PSC Cutting Tools

Overview of Halnn

Halnn is a leading provider of high-quality cutting tools, known for its commitment to innovation and customer satisfaction. Halnn's PSC cutting tools are designed to meet the highest standards of performance and reliability.

Commitment to Quality and Innovation

Halnn continually invests in research and development to ensure its products are at the forefront of cutting tool technology. The company's PSC cutting tools incorporate the latest advancements, providing users with superior performance and durability.

Range of PSC Cutting Tools

Halnn offers a comprehensive range of PSC cutting tools, including external turning tools, internal turning tools, and milling tools. Each tool is designed to deliver optimal performance and meet the specific needs of various industries.

Unique Features and Benefits of Halnn’s PSC Cutting Tools

Halnn's PSC cutting tools are known for their exceptional rigidity, quick-change capability, and high precision. These features, combined with Halnn's dedication to quality, make their PSC cutting tools a top choice for professionals seeking reliable and efficient machining solutions.

Technical Specifications

Halnn provides detailed technical specifications for its PSC cutting tools, ensuring users have all the information needed to select the right tool for their application. These specifications include material composition, manufacturing processes, and performance metrics.

How to Choose the Right PSC Cutting Tool

When selecting a PSC cutting tool, consider factors such as the material to be machined, the required surface finish, and the specific machining operation. Halnn's experts are available to assist in choosing the best tool for your needs, ensuring optimal performance and efficiency.

Maintenance and Care

Proper maintenance is crucial for extending the life of PSC cutting tools. Regular inspection, cleaning, and proper storage can help maintain tool performance. Halnn provides detailed maintenance guidelines to ensure users get the most out of their PSC cutting tools.

Customer Testimonials and Reviews

Halnn's PSC cutting tools have received positive feedback from customers across various industries. Users praise the tools' reliability, precision, and ease of use, highlighting the significant improvements in productivity and quality.

FAQs About PSC Cutting Tools

Q: What is a PSC cutting tool?

A: PSC (Polygon Shank Coupling) cutting tools are designed with a polygonal taper interface and flange contact, which provides high rigidity, stability, and quick-change capability for various machining operations. These tools adhere to the ISO 26623 standard, ensuring compatibility and reliability.

Q: What are the benefits of using PSC cutting tools?

A: PSC cutting tools offer several advantages, including:

High rigidity and stability

Quick-change capability

Enhanced tool life

High precision and accuracy

Versatility for various machining applications

Q: How do PSC cutting tools improve machining efficiency?

A: PSC cutting tools improve machining efficiency by reducing downtime with their quick-change capability, ensuring high precision with consistent and repeatable tool positioning, and minimizing vibration due to their rigid design. This leads to better surface finishes and longer tool life.

Q: What types of PSC cutting tools are available?

A: There are several types of PSC cutting tools, including:

These tools can be customized for specific machining needs.

Q: Why is the rigidity of PSC cutting tools important?

A: The rigidity of PSC cutting tools is crucial because it reduces deflection and vibration during machining. This leads to improved surface finishes, higher precision, and longer tool life, making the machining process more efficient and reliable.

Q: How does the quick-change capability of PSC cutting tools work?

A: The quick-change capability of PSC cutting tools allows for rapid tool changes with minimal effort. The polygonal taper interface ensures that tools can be swapped out quickly without losing precision, significantly reducing downtime and increasing productivity.

Q: Can PSC cutting tools be used for both turning and milling operations?

A: Yes, PSC cutting tools are versatile and can be used for both turning and milling operations. They are designed to provide optimal performance for a wide range of machining applications, making them a valuable addition to any machining setup.

Q: What industries benefit the most from using PSC cutting tools?

A: PSC cutting tools are beneficial across various industries, including:

Aerospace: For high-precision component manufacturing

Automotive: For efficient and high-quality machining

Medical device manufacturing: For precision and compliance with stringent quality standards

General engineering: For versatile and reliable machining solutions

Q: How do I maintain PSC cutting tools to ensure longevity?

A: To maintain PSC cutting tools, it is important to:

Regularly inspect for wear and damage

Clean tools properly after each use

Store tools in a dry, secure place to prevent damage

Follow manufacturer guidelines for maintenance and usage

Q: Why should I choose Halnn’s PSC cutting tools?

A: Halnn's PSC cutting tools are known for their exceptional quality, innovation, and customer-centric approach. With a commitment to providing reliable and efficient machining solutions, Halnn’s PSC cutting tools offer superior performance, durability, and value for a wide range of industrial applications.

Conclusion

PSC cutting tools represent a significant advancement in machining technology, offering unmatched rigidity, precision, and quick-change capability. Halnn, with its commitment to quality and innovation, provides a comprehensive range of PSC cutting tools designed to meet the needs of various industries. By choosing Halnn's PSC cutting tools, you can enhance your machining operations, improve productivity, and achieve superior results.

For more information or to purchase Halnn’s PSC cutting tools, please visit our website or contact our customer service team.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975