Introduction

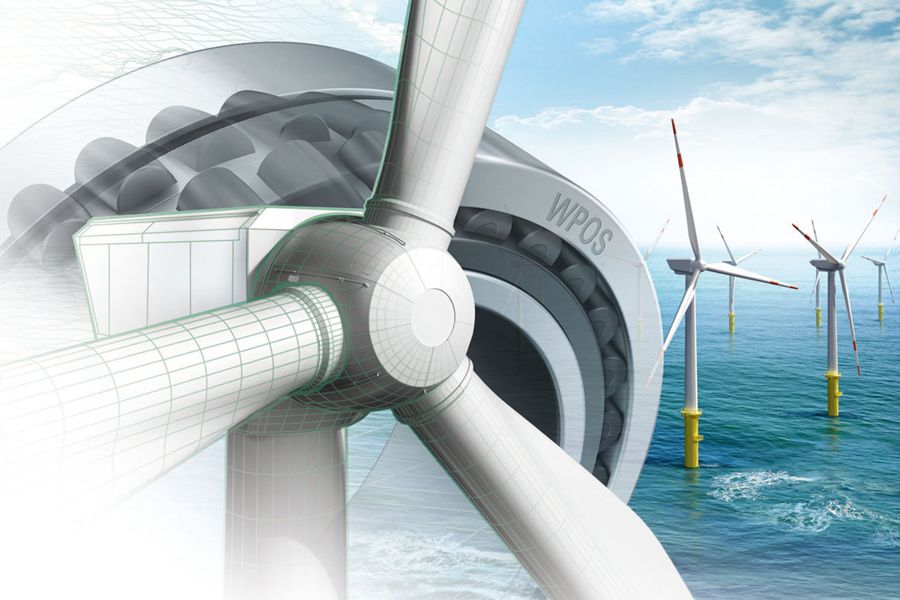

In the rapidly growing field of renewable energy, wind turbines play a crucial role in generating clean power. A key component that ensures the efficiency and longevity of these turbines is the gear system, which relies heavily on high-quality inserts. This article focuses on wind turbine gear inserts, their importance, and how Halnn's advanced solutions provide superior performance. As a leader in the industry, Halnn offers cutting-edge products that meet the demanding requirements of wind turbine applications.

Understanding Wind Turbine Gear Inserts

What Are Wind Turbine Gear Inserts?

Wind turbine gear inserts are precision-engineered components used in the gearboxes of wind turbines. These inserts are critical for the smooth transmission of power from the turbine blades to the generator, ensuring efficient energy conversion and minimal wear and tear on the gears.

Role and Importance

The gear inserts in wind turbines must withstand extreme conditions, including high loads, varying speeds, and harsh environmental factors. High-quality inserts enhance the performance and reliability of the gearbox, leading to improved overall efficiency of the wind turbine.

Materials Used

Halnn manufactures gear inserts using advanced PCBN materials. These materials offer superior hardness, wear resistance, and thermal stability, making them ideal for demanding wind turbine applications.

Benefits of Using High-Quality Gear Inserts

Enhanced Performance and Efficiency

High-quality gear inserts ensure smooth operation and efficient power transmission, reducing energy losses and improving the overall performance of wind turbines.

Increased Durability and Lifespan

Durable materials like CBN used in Halnn's inserts extend the lifespan of the gear system, reducing the frequency of maintenance and replacements.

Reduced Maintenance and Operational Costs

By minimizing wear and tear, high-quality inserts help lower maintenance requirements and operational costs, leading to significant savings over the lifespan of the wind turbine.

Improved Reliability and Reduced Downtime

Reliable gear inserts minimize the risk of unexpected failures, ensuring continuous operation and maximizing the uptime of wind turbines.

Halnn’s Wind Turbine Gear Inserts

Product Description

Halnn offers a range of advanced wind turbine gear inserts designed to meet the highest standards of performance and durability. Our inserts are made from premium materials like CBN, which provide exceptional hardness and thermal stability.

Unique Features and Advantages

Superior Hardness and Wear Resistance: Halnn’s CBN inserts offer unmatched durability, significantly reducing wear and extending the service life of the gear system.

Thermal Stability: Our inserts maintain their performance even under high-temperature conditions, ensuring reliable operation.

Precision Engineering: Halnn's inserts are manufactured to exacting standards, ensuring perfect fit and optimal performance.

Comparison with Traditional Gear Inserts

Compared to traditional inserts, Halnn's CBN gear inserts offer higher performance, longer lifespan, and reduced maintenance needs, making them a superior choice for wind turbine applications.

Advanced Materials and Technology

Materials Used

Halnn’s gear inserts are made from advanced materials like CBN and high-grade alloys, which offer superior properties compared to conventional materials.

Manufacturing Process

Our inserts are manufactured using state-of-the-art technology and precision engineering techniques, ensuring the highest quality and performance.

Advanced Coatings

Halnn applies advanced coatings to our inserts, enhancing their wear resistance and extending their service life even further.

Custom Solutions for Different Needs

Tailored Solutions

Halnn provides custom solutions to meet the specific needs of different wind turbine models and operating conditions. Our experts work closely with clients to develop inserts that deliver optimal performance.

Case Studies

Our custom solutions have been successfully implemented in various wind turbine projects, demonstrating significant improvements in performance and reliability.

Benefits of Custom Solutions

Tailored gear inserts ensure compatibility with specific turbine requirements, enhancing efficiency and reducing operational issues.

How to Choose the Right Gear Inserts

Key Factors to Consider

When selecting gear inserts, consider factors such as material properties, compatibility with the gear system, and expected operating conditions.

Matching Inserts to Turbine Specifications

It is crucial to choose inserts that match the specific requirements of the wind turbine model and its operating environment.

Evaluating Quality and Performance

Look for inserts from reputable manufacturers like Halnn, known for their precision engineering and high-quality materials.

Installation and Maintenance Tips

Best Practices for Installation

Proper installation is essential for ensuring the optimal performance of gear inserts. Follow manufacturer guidelines and use the correct tools and techniques.

Maintenance Guidelines

Regular maintenance is crucial for extending the lifespan of gear inserts. Inspect inserts periodically and replace them when signs of wear are detected.

Common Issues and Troubleshooting

Address common issues such as improper installation, excessive wear, or material incompatibility to prevent downtime and ensure smooth operation.

Future Trends in Wind Turbine Gear Inserts

Emerging Technologies

Advancements in materials science and manufacturing techniques continue to drive improvements in gear insert performance and durability.

Innovations in Design

Innovative design approaches, such as optimized geometries and advanced coatings, enhance the efficiency and lifespan of gear inserts.

Predictions for the Future

The future of wind turbine gear inserts lies in the continued development of high-performance materials and precision engineering, leading to even greater reliability and efficiency.

FAQs About Wind Turbine Gear Inserts

1. What are wind turbine gear inserts?

Wind turbine gear inserts are precision-engineered components used within the gearboxes of wind turbines. They facilitate the smooth transmission of power from the turbine blades to the generator, ensuring efficient energy conversion and reducing wear on the gears.

2. Why are wind turbine gear inserts important?

Gear inserts are crucial for maintaining the efficiency and reliability of wind turbines. They ensure smooth operation under high loads and varying speeds, which is essential for the consistent generation of electricity. High-quality inserts reduce maintenance needs and extend the lifespan of the gearbox.

3. What materials are commonly used for wind turbine gear inserts?

Wind turbine gear inserts are typically made from advanced materials such as Cubic Boron Nitride (CBN) and high-grade alloys. These materials provide superior hardness, wear resistance, and thermal stability, making them ideal for demanding applications.

4. How do Halnn's wind turbine gear inserts differ from traditional inserts?

Halnn's wind turbine gear inserts are made from premium materials like CBN, which offer exceptional hardness and thermal stability. Compared to traditional inserts, Halnn’s products provide higher performance, longer lifespan, and reduced maintenance needs.

5. What are the benefits of using CBN inserts in wind turbines?

CBN inserts offer numerous benefits, including:

Enhanced durability and wear resistance

Improved thermal stability

Longer service life, which reduces the frequency of replacements

Better performance under high-stress conditions

6. How does Halnn ensure the quality of its gear inserts?

Halnn employs state-of-the-art manufacturing techniques and precision engineering to produce gear inserts of the highest quality. Each insert undergoes rigorous testing to ensure it meets stringent performance standards.

7. Can Halnn provide custom gear insert solutions for specific wind turbine models?

Yes, Halnn offers tailored solutions to meet the unique needs of different wind turbine models and operating conditions. Our team works closely with clients to develop inserts that deliver optimal performance for their specific applications.

8. What factors should be considered when choosing wind turbine gear inserts?

When selecting gear inserts, consider factors such as:

Material properties (e.g., hardness, wear resistance, thermal stability)

Compatibility with the existing gear system

Expected operating conditions (e.g., load, speed, temperature)

Manufacturer’s reputation and quality assurance

9. How should wind turbine gear inserts be installed and maintained?

Proper installation and regular maintenance are crucial for ensuring the optimal performance of gear inserts. Follow the manufacturer’s guidelines for installation and inspect the inserts periodically for signs of wear. Replace inserts as needed to prevent gear damage and ensure continuous operation.

10. What are the common issues associated with wind turbine gear inserts and how can they be resolved?

Common issues include improper installation, excessive wear, and material incompatibility. To resolve these issues, ensure proper installation procedures are followed, choose high-quality inserts like those offered by Halnn, and regularly inspect and maintain the gear system.

11. What are the future trends in wind turbine gear inserts?

Future trends include advancements in materials science and manufacturing techniques, leading to improved performance and durability of gear inserts. Innovations in design and coating technologies will also enhance the efficiency and lifespan of these components.

12. Where can I purchase Halnn’s wind turbine gear inserts?

You can contact Halnn directly or visit our website to learn more about our products and make a purchase. Our team is ready to assist you in selecting the best gear inserts for your wind turbine applications.

Conclusion

Wind turbine gear inserts are crucial for the efficient and reliable operation of wind turbines. Halnn’s advanced solutions, made from high-quality materials like CBN, offer superior performance, durability, and cost savings. By choosing Halnn's gear inserts, operators can ensure their wind turbines operate at peak efficiency, with reduced maintenance needs and extended service life.

For more information or to purchase Halnn's wind turbine gear inserts, contact us today and discover how our products can enhance your wind turbine operations.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com

WhatsApp: +8615515925975