In the rapidly evolving manufacturing industry, precision and efficiency in gear production are crucial. The indexable gear hobbing cutter is an indispensable tool in this process. This article delves into the specifics of indexable gear hobbing cutters, highlighting their advantages, applications, and Halnn innovations in this field.

What is an Indexable Gear Hobbing Cutter?

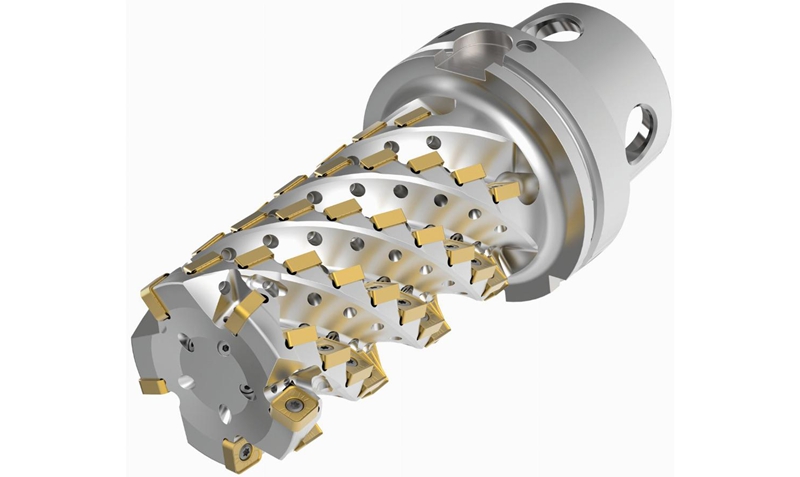

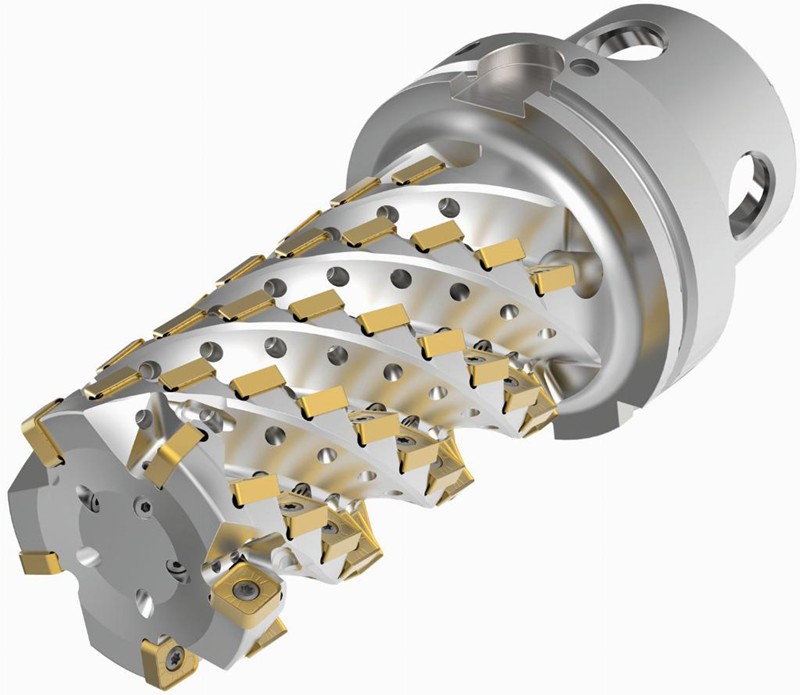

An indexable gear hobbing cutter is a specialized cutting tool used in gear manufacturing. Unlike traditional hobbing cutters that require frequent regrinding, indexable gear hobbing cutters use replaceable inserts. These inserts, made from high-performance materials such as carbide, enhance the tool's durability and cutting efficiency.

Components of an Indexable Gear Hobbing Cutter

Tool Body: The main structure that holds the inserts.

Indexable Inserts: Replaceable cutting edges that perform the actual material removal.

Clamping Mechanism: Ensures the inserts are securely held during operation.

Advantages of Using Indexable Gear Hobbing Cutters

Improved Efficiency and Productivity

Indexable gear hobbing cutters are designed for higher cutting speeds, significantly reducing cycle times. This efficiency translates into higher productivity, especially in high-volume production environments.

Cost-Effectiveness

By only replacing worn inserts rather than the entire tool, indexable gear hobbing cutters save costs over time, particularly in large-scale manufacturing operations.

Enhanced Precision and Consistency

The precision design of indexable inserts ensures consistent performance, producing high-quality gears with minimal variation. This consistency is crucial for applications requiring strict tolerances and high reliability.

Reduced Downtime

The ability to quickly replace worn inserts without dismantling the machine reduces downtime. This feature is particularly useful on production lines where any downtime can lead to significant delays and increased costs.

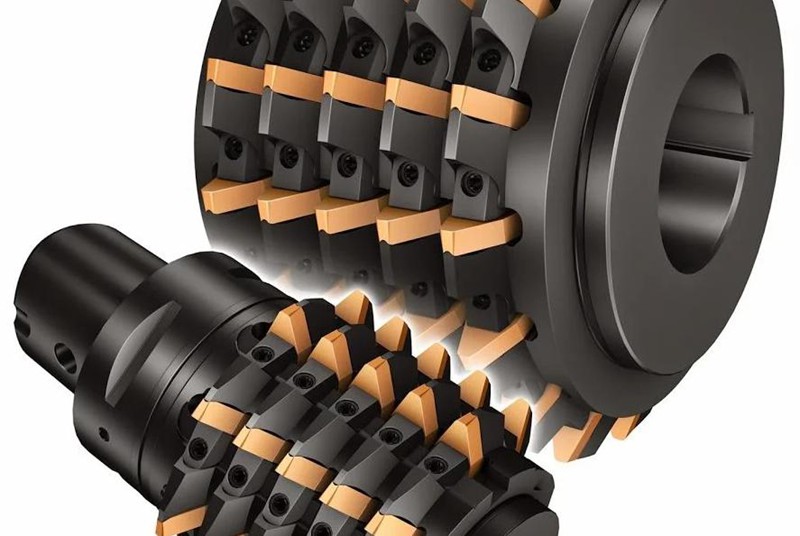

Types of Indexable Gear Hobbing Cutters

Gear Hob Cutting Tools

Designed for general gear cutting applications, these tools offer versatility and efficiency. They are suitable for various gear sizes and types, making them essential in many manufacturing setups.

Indexable Insert Gear Hobs

These hobs feature advanced insert technology, allowing for quick replacements and extended tool life. They are ideal for applications that require high precision and consistent performance.

Hobs with Indexable Carbide Inserts

Carbide inserts are known for their hardness and wear resistance. Hobs with these inserts are perfect for cutting hard materials and achieving high surface finishes.

Applications of Indexable Gear Hobbing Cutters

Automotive Industry

The automotive sector demands high precision and durability in gear production. Indexable gear hobbing cutters are widely used to produce high-quality gears for transmissions and other critical components.

Aerospace Industry

The aerospace industry requires gears with extremely high precision and reliability. Indexable gear hobbing cutters help meet these stringent requirements, ensuring that produced gears can withstand extreme conditions.

Heavy Machinery Manufacturing

Sturdy and reliable gears are essential for heavy machinery. Indexable gear hobbing cutters facilitate the production of such gears, ensuring they can handle heavy loads and continuous operation.

Other Industrial Applications

Beyond these industries, indexable gear hobbing cutters are used in various other fields requiring high-quality gear production.

Innovations by Halnn in Indexable Gear Hobbing Cutters

Halnn has been committed to developing advanced indexable gear hobbing cutters. Our tools undergo rigorous testing and quality control, designed to deliver superior performance and longevity.

Unique Features and Technologies

Halnn indexable gear hobbing cutters incorporate innovative designs that enhance cutting efficiency and tool life. Our tools combine advanced coatings and geometries to reduce cutting forces and wear.

Case Studies and Success Stories

Many leading manufacturers have benefited from Halnn gear hobbing solutions. For example, a major automotive manufacturer improved production efficiency by 30% and significantly reduced tool costs after switching to Halnn indexable gear hobbing cutters.

Customer Testimonials

"Since using Halnn indexable gear hobbing cutters, our gear production process has been transformed. The tool life and precision are unmatched, saving us considerable costs and improving product quality." – John Smith, Manufacturing Director at AutoTech Industries

Standards for Choosing Indexable Gear Hobbing Cutters

Choosing the right indexable gear hobbing cutter involves considering several factors:

Material Compatibility: Ensure the cutter is suitable for the material being machined.

Cutter Size and Geometry: Select based on the gear size and required tolerances.

Application Requirements: Consider the specific needs of the application, such as cutting speed and surface finish.

Maintenance and Care of Indexable Gear Hobbing Cutters

Best Practices

Regular inspection and maintenance of the tool and inserts are crucial for optimizing performance. Ensure inserts are replaced before excessive wear to maintain cutting efficiency.

Tips for Extending Tool Life

Use appropriate cutting parameters

Avoid excessive cutting speeds and feed rates

Ensure proper cooling and lubrication during the cutting process

Common Issues and Troubleshooting

Insert Wear: Replace inserts regularly and use the appropriate grade for the material.

Tool Vibration: Check clamping and machine stability.

Surface Finish Problems: Adjust cutting parameters and check for insert wear or damage.

Future Trends in Gear Hobbing Technology

Advances in Materials and Coatings

Developments in new materials and coatings will continue to enhance the performance and longevity of gear hobbing cutters.

Innovations in Cutter Design

Ongoing research and development are expected to bring about further improvements in cutter designs, enhancing efficiency and precision.

Impact of Industry 4.0 and Automation

The integration of smart technologies and automation will lead to more efficient and adaptive gear hobbing processes, reducing human intervention and increasing accuracy.

Frequently Asked Questions About Indexable Gear Hobbing Cutters

What are the benefits of using indexable gear hobbing cutters?

Indexable gear hobbing cutters offer numerous benefits, including improved efficiency, cost-effectiveness, high precision, and reduced downtime.

How do indexable inserts improve the gear hobbing process?

Indexable inserts allow for quick replacement, consistent performance, and reduced tool costs, enhancing the overall gear hobbing process.

Can indexable gear hobbing cutters be used for precision applications?

Yes, with advancements in design and materials, indexable gear hobbing cutters can achieve high precision, suitable for demanding applications.

How do I choose the right indexable gear hobbing cutter for my application?

When choosing an indexable gear hobbing cutter, consider material compatibility, cutter size and geometry, and the specific needs of the application.

Conclusion

Indexable gear hobbing cutters are revolutionizing the gear manufacturing industry through their efficiency, precision, and cost-effectiveness. Halnn is at the forefront of this innovation, providing advanced tools that meet the demands of modern manufacturing. By choosing Halnn indexable gear hobbing cutters, you invest in tools that offer exceptional performance and longevity.

For more information on Halnn indexable gear hobbing cutters and to discuss your specific needs, please visit our website or contact our sales team. Let Halnn help you achieve unparalleled precision and efficiency in your gear manufacturing process.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com