Introduction

Gear machining is a critical aspect of manufacturing in various industries, ranging from automotive to aerospace. The precision and efficiency of gear production directly impact the performance and reliability of machinery. Halnn, a leader in innovative tooling solutions, provides advanced indexable gear machining tools designed to meet the stringent demands of modern manufacturing. This article delves into the features, benefits, and applications of these tools, offering valuable insights for professionals seeking to enhance their gear machining processes.

What are Indexable Gear Machining Tools?

Indexable gear machining tools are cutting instruments equipped with replaceable inserts that can be rotated or swapped out when they become worn. Unlike traditional tools, which require the entire tool to be replaced or re-sharpened, indexable tools offer significant advantages in terms of cost and convenience. These tools are designed to maintain high precision and efficiency in gear production.

Features of Indexable Gear Machining Tools

Replaceable Inserts: Allow for quick and easy tool maintenance.

High Precision: Ensure accurate gear profiles and surface finishes.

Durability: Made from advanced materials that withstand high cutting forces.

Benefits of Using Indexable Gear Machining Tools

Enhanced Precision and Accuracy

Indexable gear machining tools are engineered to provide superior accuracy in gear cutting. The replaceable inserts are manufactured to exact specifications, ensuring consistent performance and minimizing deviations in gear profiles.

Improved Efficiency and Reduced Machining Time

The ability to quickly replace worn inserts without removing the entire tool from the machine reduces downtime. This leads to higher productivity and shorter production cycles, which are crucial in high-volume manufacturing environments.

Cost-Effectiveness and Tool Longevity

While the initial investment in indexable tools may be higher, the long-term savings are substantial. The inserts can be replaced individually, which is more economical than replacing or re-sharpening traditional tools.

Easy Replacement of Cutting Inserts

The design of indexable tools allows for straightforward replacement of inserts, which can be done quickly and with minimal training. This simplifies maintenance and reduces the need for specialized skills.

Types of Indexable Gear Machining Tools

Indexable Gear Hobbing Tools

These tools are used for generating gear teeth through a continuous cutting process. They are ideal for high-speed production of gears with excellent surface finish and accuracy.

Indexable Gear Shaping Tools

Designed for cutting internal and external gears, these tools provide flexibility and precision in various gear manufacturing applications.

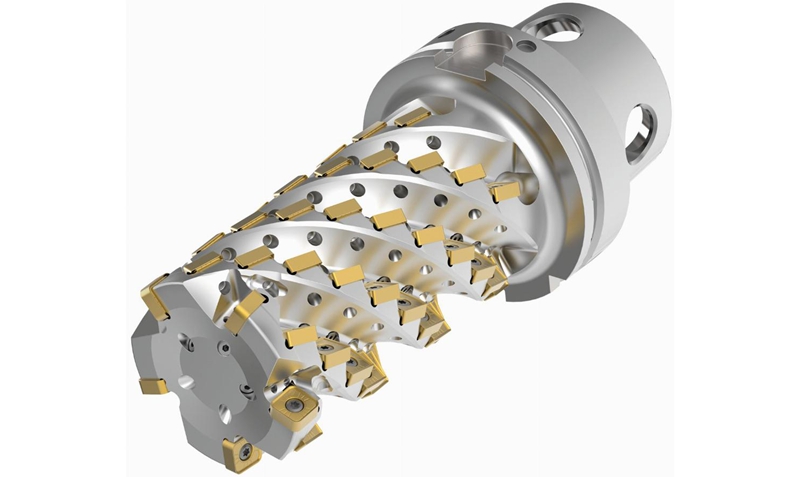

Indexable Gear Milling Tools

These tools are used for cutting gear teeth using a milling process. They are suitable for producing complex gear profiles with high precision.

Custom Solutions by Halnn

Halnn offers customized indexable gear machining tools tailored to specific customer requirements. This ensures optimal performance and efficiency in unique manufacturing scenarios.

Applications of Indexable Gear Machining Tools

Automotive Industry

High-precision gears are essential for automotive components, including transmissions and differentials. Indexable tools ensure the production of reliable and efficient gears.

Aerospace Industry

The aerospace sector demands gears with tight tolerances and exceptional performance. Indexable gear machining tools meet these stringent requirements.

Heavy Machinery Manufacturing

Heavy machinery relies on robust and durable gears. Indexable tools provide the necessary strength and precision for these applications.

Precision Engineering

Indexable gear machining tools are used in precision engineering applications where accuracy and surface finish are paramount.

How to Choose the Right Indexable Gear Machining Tool

Factors to Consider

Material: The type of material being machined will influence the choice of tool.

Machining Conditions: Speed, feed rate, and cutting environment should be considered.

Specific Requirements: The desired gear profile and finish will dictate the tool specifications.

Comparing Different Types of Indexable Tools

Evaluating the benefits of gear hobbing, shaping, and milling tools can help in selecting the most appropriate tool for a given application.

Tips for Optimizing Performance and Tool Life

Regular maintenance and proper handling of inserts.

Using the correct cutting parameters for the material.

Ensuring the machine setup is accurate and stable.

Halnn’s Expertise in Indexable Gear Machining Tools

Overview of Halnn’s Product Range and Innovations

Halnn offers a comprehensive range of indexable gear machining tools that leverage the latest technological advancements to deliver unmatched performance and reliability.

Case Studies and Success Stories

Real-world examples of how Halnn’s tools have improved manufacturing processes and outcomes for various clients.

Customer Testimonials and Feedback

Feedback from satisfied customers highlighting the quality and effectiveness of Halnn’s indexable gear machining tools.

Maintenance and Care for Indexable Gear Machining Tools

Best Practices for Tool Maintenance

Common Issues and Troubleshooting Tips

Recommendations for Maximizing Tool Life

FAQs About Indexable Gear Machining Tools

1. What are indexable gear machining tools?

Indexable gear machining tools are specialized cutting instruments used in the manufacturing of gears. These tools feature replaceable inserts that can be rotated or swapped out when they become worn, providing an efficient and cost-effective solution for gear production.

2. What are the advantages of using indexable gear machining tools?

The main advantages include:

Cost Efficiency: Replaceable inserts reduce the need to replace the entire tool.

Increased Productivity: Quick insert changes minimize downtime.

Enhanced Precision: Maintains high accuracy in gear cutting.

Durability: Made from high-quality materials that withstand high cutting forces.

3. How do indexable gear machining tools differ from traditional gear cutting tools?

Traditional gear cutting tools often require complete replacement or re-sharpening, which can be time-consuming and costly. In contrast, indexable tools allow for quick and easy replacement of worn inserts, maintaining consistent performance without the need for frequent tool changes.

4. What types of indexable gear machining tools are available?

Indexable Gear Hobbing Tools: Used for generating gear teeth through continuous cutting.

Indexable Gear Shaping Tools: Suitable for cutting internal and external gears.

Indexable Gear Milling Tools: Used for milling gear teeth with high precision.

5. How do I choose the right indexable gear machining tool for my application?

Consider factors such as the material being machined, the specific gear profile required, machining conditions (speed, feed rate), and the desired surface finish. Consulting with a supplier like Halnn can help you select the most suitable tool for your needs.

6. What maintenance is required for indexable gear machining tools?

Regular inspection and cleaning are essential to maintain tool performance. Ensure proper handling and storage of inserts, use the correct cutting parameters, and monitor for wear patterns to address issues promptly.

7. Can indexable gear machining tools be used for both high-volume and precision applications?

Yes, indexable gear machining tools are versatile and can be used in high-volume production environments as well as applications requiring high precision and tight tolerances.

8. What materials are commonly machined with indexable gear tools?

Indexable gear machining tools can be used on a variety of materials, including steels, stainless steels, and other alloys commonly used in gear manufacturing.

9. How do I maximize the life of my indexable gear machining tools?

To maximize tool life, follow best practices such as using appropriate cutting parameters, ensuring accurate machine setup, performing regular maintenance, and replacing inserts before they become excessively worn.

10. Are there any industry-specific applications for indexable gear machining tools?

Yes, these tools are widely used in industries such as automotive, aerospace, heavy machinery manufacturing, and precision engineering due to their ability to produce high-quality gears efficiently and accurately.

11. How can Halnn's indexable gear machining tools benefit my production process?

Halnn’s tools are designed to offer superior performance, reliability, and cost-effectiveness. By incorporating Halnn’s indexable gear machining tools, you can achieve higher precision, increased productivity, and lower overall production costs.

12. Where can I purchase Halnn’s indexable gear machining tools?

Halnn’s indexable gear machining tools can be purchased directly from Halnn or through authorized distributors. Contact Halnn for more information on product availability and customization options.

Conclusion

Indexable gear machining tools are a vital component in modern manufacturing, offering precision, efficiency, and cost-effectiveness. Halnn’s expertise and innovative solutions provide the perfect answer to the challenges of gear production. For more information and to explore our range of indexable gear machining tools, contact Halnn today.

Our website: https://www.halnncbn.com/

Mail address: halnntools@halnn-group.com