In the realm of crankshaft machining, precision and efficiency are paramount. The choice of tools can significantly impact the quality and productivity of machining operations. Halnn, a leader in cutting tool technology, offers advanced indexable crankshaft milling tools designed to meet the rigorous demands of modern manufacturing.

What is an Indexable Crankshaft Milling Tool?

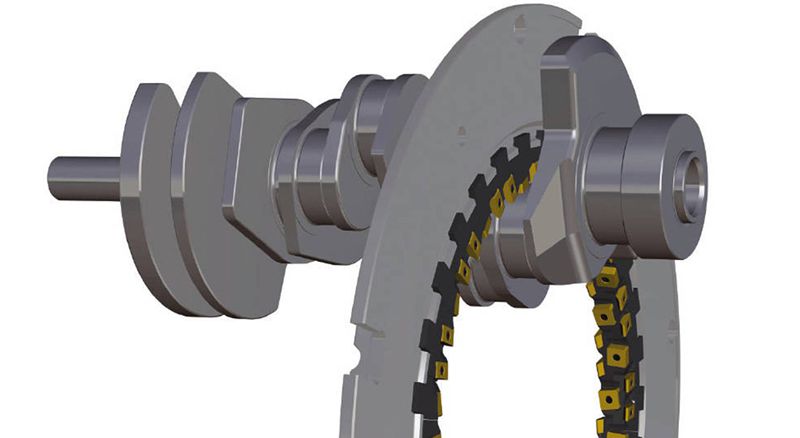

An indexable crankshaft milling tool is a specialized cutting tool used in the machining of crankshafts. Unlike traditional solid tools, these tools feature replaceable inserts that can be indexed, or rotated, to expose a fresh cutting edge. This design not only extends the tool's life but also enhances cutting performance and reduces downtime for tool changes.

Advantages of Using Indexable Crankshaft Milling Tools

Enhanced Cutting Efficiency

Indexable crankshaft milling tools are engineered to provide superior cutting efficiency. The replaceable inserts are made from high-quality materials that maintain sharpness and durability, enabling faster cutting speeds and feed rates. This results in shorter cycle times and increased productivity.

Cost-Effectiveness

One of the key benefits of indexable tools is their cost-effectiveness. Instead of replacing the entire tool, operators can simply replace the worn inserts. This reduces the overall tooling costs and ensures consistent performance without the need for frequent tool changes.

Improved Tool Life and Performance

The design of Halnn indexable crankshaft milling tools ensures optimal tool life. The inserts are manufactured using advanced materials and coatings that resist wear and heat, providing reliable performance over extended periods. This translates to fewer interruptions and higher machining efficiency.

Precision and Consistency

Precision is crucial in crankshaft machining, and Halnn tools deliver exceptional accuracy. The multiple cutting edges on the inserts ensure uniform material removal, resulting in consistent surface finishes and dimensional accuracy. This precision is essential for meeting the stringent tolerances required in crankshaft manufacturing.

Key Features of Halnn Indexable Crankshaft Milling Tools

High-Quality Materials and Construction

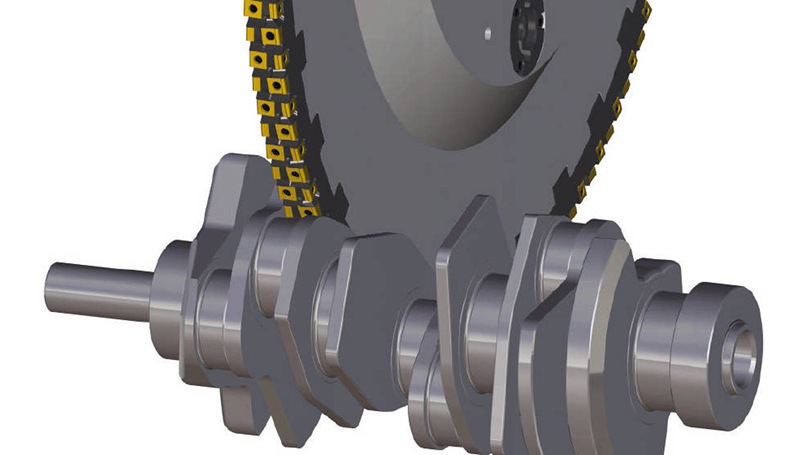

Halnn indexable crankshaft milling tools are crafted from premium materials to withstand the demanding conditions of crankshaft machining. The tool bodies are robust and durable, ensuring stability and reducing vibrations during operation.

Advanced Design for Optimal Performance

The tools are designed with cutting-edge technology to optimize performance. The insert geometries are tailored to enhance chip evacuation and reduce cutting forces, leading to smoother and more efficient machining processes.

Customizable Inserts for Various Machining Needs

Halnn offers a range of inserts for different machining applications. Whether it's roughing, finishing, or semi-finishing, Halnn indexable inserts cater to diverse needs, ensuring versatility and adaptability in various manufacturing environments.

Integration with Modern CNC Machines

Halnn tools are compatible with modern CNC machines, allowing seamless integration into automated manufacturing systems. This compatibility enhances the precision and repeatability of machining operations, ensuring high-quality outcomes.

Types of Indexable Inserts for Crankshaft Milling

Roughing Inserts

Designed for initial material removal, roughing inserts handle heavy cuts and high feed rates. They are robust and durable, capable of withstanding the stresses of rough machining.

Finishing Inserts

Finishing inserts are used for the final machining pass, providing a smooth surface finish and precise dimensional control. These inserts are designed to minimize cutting forces and vibrations, ensuring high-quality results.

Semi-Finishing Inserts

Semi-finishing inserts bridge the gap between roughing and finishing. They are used to remove intermediate material, preparing the workpiece for the final finishing pass.

Applications of Indexable Crankshaft Milling Tools

Automotive Industry

In the automotive industry, crankshaft milling is a critical process. Halnn indexable tools are used for machining main journals, pin journals, and other critical areas of crankshafts, ensuring high performance and reliability of engines.

General Manufacturing

Besides automotive industry, Halnn indexable crankshaft milling tools are utilized in various manufacturing sectors where crankshaft machining is required, providing versatile solutions for diverse applications.

How to Choose the Right Indexable Crankshaft Milling Tool

Factors to Consider

When selecting an indexable crankshaft milling tool, consider the material of the crankshaft, the machining conditions, and the desired outcomes. Factors such as cutting speed, feed rate, and the type of machining (roughing, semi-finishing, or finishing) are crucial in making the right choice.

Tips for Selecting the Right Inserts

Choose inserts that match the specific requirements of your machining process. Halnn offers a variety of inserts with different geometries and coatings to suit various applications. Consult with Halnn experts to ensure you select the best tools for your needs.

Halnn Assistance in Tool Selection

Halnn provides comprehensive support to customers in selecting the right tools. Their experienced team offers guidance and recommendations based on your specific machining requirements, ensuring optimal tool performance and longevity.

Maintenance and Care for Indexable Crankshaft Milling Tools

Proper Handling and Storage

To maintain the performance and longevity of indexable tools, proper handling and storage are essential. Keep tools and inserts in a clean, dry environment to prevent damage and corrosion.

Maximizing Tool Life and Performance

Regular inspection and maintenance of tools and inserts can significantly extend their life. Replace worn or damaged inserts promptly to ensure consistent cutting performance. Follow Halnn guidelines for tool care and maintenance.

Troubleshooting Common Issues

Address common issues such as insert chipping or excessive wear by reviewing machining parameters and ensuring proper tool setup. Halnn technical support team is available to assist with troubleshooting and resolving any challenges you may encounter.

Innovations in Indexable Crankshaft Milling Technology

Recent Advancements

Halnn continuously invests in research and development to enhance its products. Recent advancements in insert materials and coatings have led to improved wear resistance and cutting performance.

Innovations in Tool Design and Geometry

Innovations in tool design and geometry have optimized chip evacuation and reduced cutting forces, resulting in smoother and more efficient machining processes. Halnn tools incorporate these advancements to deliver superior results.

Future Trends

Future trends in crankshaft milling tools include further improvements in insert materials, coatings, and tool geometries. Halnn remains at the forefront of these developments, ensuring their customers benefit from the latest technological advancements.

Why Choose Halnn for Indexable Crankshaft Milling Tools?

Expertise and Experience

With years of experience in the cutting tool industry, Halnn is a trusted name in crankshaft milling. Their expertise and commitment to quality ensure that customers receive the best tools and support.

Customer Testimonials and Success Stories

Halnn customers consistently report high satisfaction with their products and services. Testimonials and success stories highlight the effectiveness and reliability of Halnn indexable crankshaft milling tools.

Commitment to Quality and Customer Satisfaction

Halnn is dedicated to providing high-quality products and exceptional customer service. Their commitment to continuous improvement and customer satisfaction sets them apart in the industry.

FAQs About Indexable Crankshaft Milling Tools

1. What is an indexable crankshaft milling tool?

An indexable crankshaft milling tool is a cutting tool designed specifically for machining crankshafts. It features replaceable inserts that can be indexed, or rotated, to present a fresh cutting edge, enhancing tool life and cutting efficiency.

2. What are the benefits of using indexable crankshaft milling tools?

Indexable crankshaft milling tools offer several benefits:

Cost-Effectiveness: Replaceable inserts reduce the need for frequent tool changes, lowering overall tooling costs.

Efficiency: They allow for higher cutting speeds and feed rates, increasing productivity.

Precision: The design ensures consistent material removal and high-quality surface finishes.

Durability: Advanced materials and coatings extend tool life and performance.

3. How do I choose the right indexable crankshaft milling tool?

When selecting an indexable crankshaft milling tool, consider the following factors:

Material of the Crankshaft: Different materials require specific insert grades and geometries.

Machining Conditions: Assess the cutting speed, feed rate, and depth of cut.

Desired Outcome: Determine whether you need roughing, semi-finishing, or finishing operations.

4. How often should I replace the inserts on my indexable crankshaft milling tool?

The frequency of replacing inserts depends on the machining conditions and material being processed. Regular inspection of the inserts for wear and damage is essential. Replace inserts promptly when they show signs of wear to maintain optimal performance and precision.

5. Can Halnn's indexable crankshaft milling tools be used with modern CNC machines?

Yes, Halnn's indexable crankshaft milling tools are compatible with modern CNC machines. Their design allows for seamless integration into automated systems, enhancing precision and repeatability in machining operations.

6. What maintenance practices should I follow for indexable crankshaft milling tools?

To ensure the longevity and performance of your tools, follow these maintenance practices:

Proper Handling and Storage: Keep tools and inserts in a clean, dry environment.

Regular Inspection: Check for wear and damage regularly.

Timely Replacement: Replace worn or damaged inserts promptly.

Adherence to Guidelines: Follow Halnn's guidelines for tool care and maintenance.

7. What recent advancements have been made in indexable crankshaft milling tools?

Recent advancements include:

Improved Insert Materials and Coatings: Enhanced wear resistance and cutting performance.

Optimized Tool Geometries: Better chip evacuation and reduced cutting forces.

Advanced Design Features: Innovations in tool design for smoother and more efficient machining processes.

8. Why should I choose Halnn for my indexable crankshaft milling tool needs?

Halnn is a trusted name in cutting tool technology, offering:

Expertise and Experience: Years of experience in the industry.

High-Quality Products: Reliable and durable tools.

Customer Support: Comprehensive support and guidance in tool selection and maintenance.

Innovation: Continuous improvement and adoption of the latest technological advancements.

Conclusion

Halnn indexable crankshaft milling tools offer unmatched efficiency, precision, and cost-effectiveness for crankshaft machining. With a commitment to quality and innovation, Halnn provides reliable solutions that meet the demands of modern manufacturing. For more information or to explore Halnn range of products, contact Halnn today.

Mail address: halnntools@halnn-group.com