In the precision manufacturing industry, crankshaft milling is a critical process that ensures the optimal performance of engines. At the heart of this process are the crankshaft milling cutters, essential tools for achieving high-quality results. This article delves into the specifics of internal crankshaft milling cutters, with a special focus on Halnn advanced solutions. We will explore the features, benefits, and applications of these tools to provide valuable insights and promote Halnn offerings.

Understanding Internal Crankshaft Milling Cutters

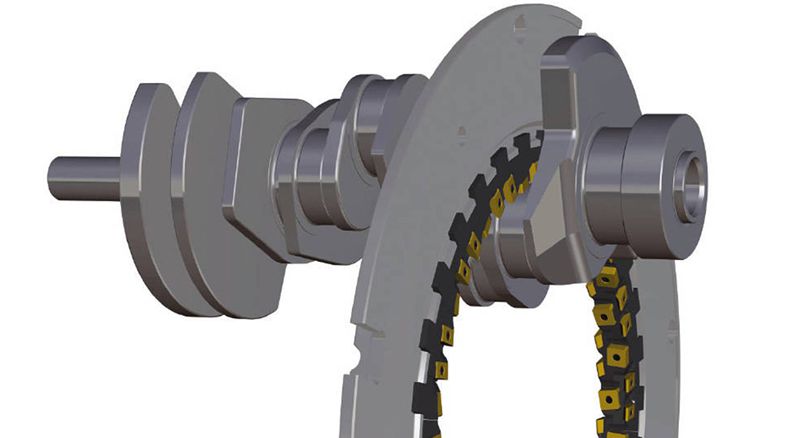

Internal crankshaft milling cutters are specialized tools designed for machining the internal surfaces of crankshafts, such as journals and bores. These cutters differ from external crankshaft milling cutters, which handle the outer surfaces. The precision required for internal milling is critical for ensuring the crankshaft’s functionality and overall engine performance. Halnn's internal crankshaft milling cutters are engineered to meet these high standards, offering unparalleled precision and efficiency.

Features of Halnn Internal Crankshaft Milling Cutters

Halnn internal crankshaft milling cutters are renowned for their superior quality and performance. Key features include:

High-Quality Materials: Made from top-grade materials like carbide and high-speed steel, ensuring durability and longevity.

Innovative Design: Engineered to provide optimal cutting speeds and feed rates, reducing machining time while maintaining high precision.

Advanced Engineering: Designed to minimize tool wear and extend tool life, making them a cost-effective choice for manufacturers.

Applications and Benefits of Internal Crankshaft Milling Cutters

Applications

Halnn internal crankshaft milling cutters are used across various industries, including automotive, aerospace, and industrial manufacturing. They are particularly vital in applications where precision and efficiency are paramount.

Benefits

Improved Accuracy: High precision in internal milling leads to better engine performance and longevity.

Reduced Machining Time: Optimized design and material choice enable faster machining processes.

Enhanced Engine Performance: Precision machining contributes to smoother engine operation and increased fuel efficiency.

Cost-Effective: Durable materials and design extend tool life, reducing overall costs.

Case Studies

Numerous case studies from Halnn clients showcase significant improvements in production efficiency and product quality. For instance, automotive manufacturers have reported smoother engine operations and reduced fuel consumption due to the high precision of Halnn internal crankshaft milling cutters.

Technical Specifications

Halnn provides a range of internal crankshaft milling cutters in various sizes, shapes, and types to meet diverse manufacturing needs. These cutters are compatible with CNC machines and other modern manufacturing equipment, ensuring seamless integration into existing production lines. Detailed specifications of each product variant are available to help customers choose the right tool for their specific applications.

Choosing the Right Internal Crankshaft Milling Cutter

When selecting an internal crankshaft milling cutter, consider factors such as material type, cutting speed, and feed rate. Halnn offers expert advice and consultation to help you choose the right cutter for your specific application, ensuring optimal performance and longevity.

Maintenance and Care

Proper maintenance is crucial for maximizing the lifespan of your internal crankshaft milling cutters. Regular inspection, cleaning, and proper storage are essential. Halnn provides comprehensive sharpening and reconditioning services to keep your tools in top condition.

Best Practices

Inspection: Regularly check for wear and damage.

Cleaning: Keep the cutters clean and free of debris.

Storage: Store in a dry, secure place to prevent damage.

Sharpening: Utilize Halnn sharpening services to maintain cutting efficiency.

Customer Support and Services

Halnn is dedicated to providing excellent customer support and after-sales services. Our team of experts is available for technical assistance and consultation, ensuring you get the most out of your internal crankshaft milling cutters. We also offer warranty and guarantee options for added peace of mind.

Conclusion

Internal crankshaft milling cutters are indispensable tools for precision manufacturing in various industries. Halnn cutters stand out for their quality, durability, and innovative design, making them the preferred choice for manufacturers worldwide. For more information or to make a purchase, contact Halnn today.

FAQs About Internal Crankshaft Milling Cutters

1. What is an internal crankshaft milling cutter?

An internal crankshaft milling cutter is a specialized tool designed to machine the internal surfaces of crankshafts, such as journals and bores. These cutters ensure high precision and accuracy in creating smooth, functional surfaces inside the crankshaft.

2. How does an internal crankshaft milling cutter differ from an external crankshaft milling cutter?

Internal crankshaft milling cutters are used for machining the inner surfaces of crankshafts, whereas external crankshaft milling cutters are designed for the outer surfaces. The internal cutters focus on areas like journals and bores, which require high precision for optimal engine performance.

3. What are the benefits of using Halnn's internal crankshaft milling cutters?

Halnn's internal crankshaft milling cutters offer several benefits, including:

High precision and accuracy

Reduced machining time

Enhanced durability and tool life

Cost-effectiveness due to longer tool life and less frequent replacements

4. What materials are Halnn internal crankshaft milling cutters made from?

Halnn internal crankshaft milling cutters are typically made from high-quality materials such as carbide. These materials ensure durability, high performance, and a longer lifespan for the cutting tools.

5 How do I choose the right internal crankshaft milling cutter for my application?

To choose the right internal crankshaft milling cutter, consider factors such as the material to be machined, the required cutting speed, feed rate, and the specific dimensions of the crankshaft. Halnn offers professional consultation to help you select the most suitable cutter for your needs.

6. What industries commonly use internal crankshaft milling cutters?

Internal crankshaft milling cutters are commonly used in industries such as automotive, aerospace, and industrial manufacturing. These cutters are crucial in applications where precision and efficiency in crankshaft production are paramount.

7. How can I maintain my internal crankshaft milling cutter for optimal performance?

Proper maintenance practices include:

Regular inspection for wear and damage

Keeping the cutters clean and free from debris

Storing the cutters in a dry, secure place

Utilizing sharpening and reconditioning services provided by Halnn to maintain cutting efficiency

8. Are Halnn internal crankshaft milling cutters compatible with CNC machines?

Yes, Halnn internal crankshaft milling cutters are designed to be compatible with CNC machines and other modern manufacturing equipment, ensuring seamless integration into existing production lines.

9. What makes Halnn internal crankshaft milling cutters stand out from the competition?

Halnn internal crankshaft milling cutters stand out due to their innovative design, use of high-quality materials, advanced engineering, and the ability to deliver high precision and durability. These factors contribute to improved manufacturing efficiency and product quality.

10. Can Halnn provide custom internal crankshaft milling cutters for specific applications?

Yes, Halnn offers custom solutions tailored to specific customer requirements. By providing detailed specifications and consulting with Halnn's experts, customers can get bespoke internal crankshaft milling cutters that meet their unique needs.