Introduction

Wind energy is a cornerstone of renewable energy strategies worldwide. The efficiency and performance of wind turbines are critically dependent on the quality and precision of their blades. Drilling is a vital process in the manufacturing and assembly of wind turbine blades, ensuring structural integrity and optimal performance. This article delves into the intricacies of wind turbine blade drilling, exploring advanced tools, techniques, and innovations. Additionally, it highlights how Halnn's state-of-the-art machining solutions are driving advancements in this field.

Importance of Drilling in Wind Turbine Blades

Drilled holes in wind turbine blades are essential for various functions, including mounting, assembly, and integration of sensors. These holes ensure secure attachment to the hub and other components, which is critical for the overall stability and functionality of the turbine. Precision in drilling is paramount as any deviation can impact the aerodynamic efficiency and structural integrity of the blades, leading to performance issues and potential failures.

Materials Used in Wind Turbine Blades

Wind turbine blades are typically made from composite materials such as fiberglass-reinforced plastic (FRP) and carbon fiber. These materials offer the necessary strength, durability, and lightweight properties needed to endure harsh environmental conditions and mechanical stresses. However, their unique properties, including high abrasiveness and varying hardness, pose significant challenges in the drilling process.

Halnn's Advanced Drilling Solutions

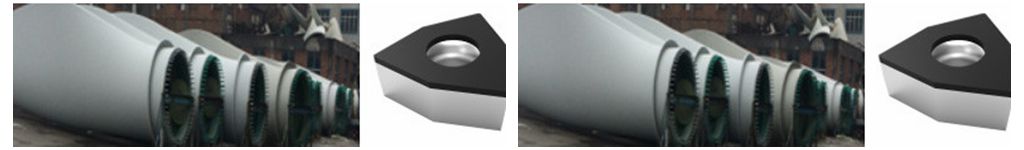

Superior Tool Selection

Halnn offers a range of PCD (polycrystalline diamond) inserts specifically designed for drilling wind turbine blades. These inserts are renowned for their extreme hardness and wear resistance, making them ideal for the tough, abrasive composite materials used in blade construction.

Customized Tool Geometry

Halnn PCD bits are customized to meet the specific requirements of wind turbine blade drilling. This customization reduces the risk of glass fiber delamination or blade damage, ensuring superior hole quality and structural integrity.

Optimized Machining Parameters

The machining parameters—cutting speed, feed rate, and cutting depth—are carefully selected to balance productivity with tool life and hole quality. Compared with traditional tools, Halnn PCD tools can operate at higher cutting speeds and feed rates, significantly enhancing drilling speed and accuracy.

Key Considerations in Drilling Wind Turbine Blades

Precision and Accuracy Requirements

High precision in drilling is vital to ensure proper blade assembly and structural integrity. Tight tolerances must be maintained throughout the process to avoid misalignment and compromised stability.

Surface Finish and Aerodynamics

The surface finish of drilled holes directly impacts the aerodynamic efficiency of the wind turbine blades. A smooth, high-quality finish reduces drag and ensures proper load distribution, enhancing overall turbine performance.

Tool Wear and Material Removal Rates

Balancing material removal rates with tool wear is essential for efficient drilling. Optimizing cutting parameters helps achieve high productivity while maintaining tool life. Excessive tool wear can lead to poor surface finishes and dimensional inaccuracies, necessitating frequent tool changes.

Cooling and Lubrication Strategies

Effective cooling and lubrication prevent overheating and reduce tool wear. Strategies such as high-pressure coolant systems can enhance cutting performance and ensure consistent quality. In some cases, dry machining may be employed to avoid potential contamination from coolants.

Challenges and Solutions in Wind Turbine Blade Drilling

Common Challenges

Tool Wear: The abrasive nature of wind turbine materials causes rapid tool wear.

Delamination: Improper drilling can cause layers to separate, compromising structural integrity.

Heat Management: Excessive heat can damage both the PCD inserts and the wind turbine blades.

Vibration: Ensuring machine stability to achieve precise cuts.

Best Practices and Solutions

Advanced Tool Materials: Using Halnn PCD tools made from PCD for better wear resistance in wind turbine blade drilling.

Optimized Cutting Parameters: Balancing speed, feed rate, and depth of cut to minimize defects.

Stable Machining Conditions: Ensuring rigid setups and balanced cutting parameters to minimize vibrations.

Automated Material Handling: Utilizing automated systems to handle large blades, reducing the risk of damage and improving safety.

Case Studies and Industry Applications

Success Stories

Halnn has partnered with several wind turbine manufacturers to implement advanced drilling solutions. These case studies highlight significant improvements in production efficiency, hole quality, and cost savings. For example, a leading manufacturer reported a 30% increase in production speed and a 20% reduction in material waste after adopting Halnn advanced tools.

Industry Testimonials

Clients have praised Halnn for providing reliable and high-performance drilling tools, contributing to their success in the renewable energy sector. Testimonials underscore the effectiveness and value of Halnn Group's solutions.

Conclusion

Wind turbine blade drilling is a critical process that demands precision, efficiency, and advanced technology. By understanding the challenges and adopting innovative tools and techniques, manufacturers can significantly improve the quality and performance of wind turbine blades. Halnn is at the forefront of this industry, providing high-quality machining tools and solutions that drive the future of renewable energy. With a focus on sustainability and continuous improvement, Halnn remains a trusted partner for manufacturers worldwide.

About Halnn

Halnn is a leader in the development and supply of advanced machining tools. With a commitment to quality and innovation, Halnn offers a comprehensive range of products designed to meet the demanding needs of the wind turbine manufacturing industry. Our expertise and dedication to customer satisfaction have made us a trusted partner for manufacturers worldwide. Explore our range of products and services, and join us in driving the future of sustainable manufacturing. For more information, visit Halnn official website: halnnpcd.

FAQs of Wind Turbine Blade Drilling

1. What materials are wind turbine blades made from?

Wind turbine blades are typically made from composite materials such as fiberglass-reinforced plastic (FRP) and carbon fiber. These materials offer the necessary strength, durability, and lightweight properties required to withstand environmental conditions and mechanical stresses.

2. Why is precision important in wind turbine blade drilling?

Precision is crucial in wind turbine blade drilling to ensure proper assembly and structural integrity. Accurate drilling helps maintain the aerodynamic efficiency of the blades and prevents potential performance issues and failures.

3. What are the common challenges faced in drilling wind turbine blades?

Common challenges in drilling wind turbine blades include tool wear, delamination, heat management, and vibration. These challenges arise due to the abrasive nature of composite materials and the need for high precision.

4. What types of drilling tools are used for wind turbine blades?

Drilling tools for wind turbine blades include carbide drills, diamond-coated drills, and polycrystalline diamond (PCD) tools. These tools are selected based on their ability to handle the specific properties of composite materials and provide precise, high-quality holes.

5. How does CNC drilling improve the drilling process for wind turbine blades?

CNC (Computer Numerical Control) drilling improves the process by offering high precision, repeatability, and efficiency. CNC machines can handle complex shapes and large sizes of blades, performing multiple drilling operations in a single setup with exact specifications.

6. What are some advanced drilling techniques used for wind turbine blades?

Advanced drilling techniques include ultrasonic drilling and laser drilling. Ultrasonic drilling uses high-frequency vibrations to reduce cutting forces and minimize delamination, while laser drilling provides high precision for creating small, intricate holes.

7. How is Halnn contributing to advancements in wind turbine blade drilling?

Halnn is at the forefront of innovation in wind turbine blade drilling, offering high-quality machining tools and solutions. The company focuses on developing eco-friendly tools, optimizing drilling processes, and investing in research and development to drive advancements in the renewable energy sector.

8. What future trends are expected in wind turbine blade drilling?

Future trends in wind turbine blade drilling include increased automation and robotics, the use of digital twin and simulation technologies for process optimization, and the development of more advanced and sustainable machining tools and techniques. These innovations aim to enhance efficiency, precision, and environmental sustainability in the manufacturing process.