PCD tools have unique advantages in machining aluminum alloy and composite parts due to their high precision, high efficiency and long life. In order to meet the market demand, Halnn continuously enriches the PCD tool production line, on the basis of PCD turning tools, PCD milling tools, PCD drills, PCD boring tools, PCD reamers, innovatively launched PCD chipbreaker inserts, PCD full-face inserts, PCD High Finish tools, and PCD milling inserts repairing or replacement services:

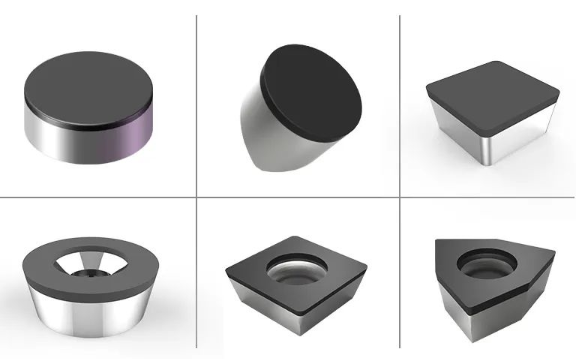

1.PCD full-face inserts

Halnn new generation of full-face PCD tools: for wind turbine bearing ball groove hard turning, Halnn provides RNGN full-face PCD/PCBN inserts with high wear resistance to realize high-quality finishing. For wind turbine blade flange hole drilling, Halnn offers PCD fully laminated U drill inserts with excellent wear resistance, mainly W-shaped and S-shaped, which can be indexed 3-4 times to reduce production costs, and at the same time, it can withstand higher cutting speeds and feed speeds, combined with excellent rigidity of the tool holder, to achieve stable and efficient drilling while maintaining dimensional accuracy. For tungsten carbide roller rings (hardness>HRA88), Halnn offers the fully laminated PCD insert RCGX model.

Applications range:

Application Case:

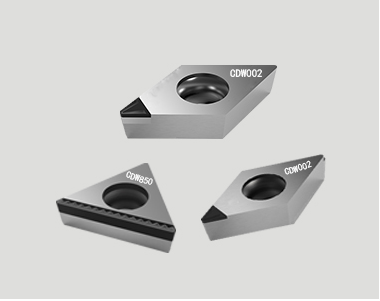

2.New Generation Breaking-G Series PCD Chip Breaker Inserts

Halnn new generation of PCD chipbreaking tools Breaking-G series can effectively solve the problem of non-chip breaking and greatly improve the working efficiency, with better stability, higher service life and wider range of applications, to achieve outstanding chipbreaking effect in finishing and semi-finishing aluminum alloy, with a variety of chipbreaking grooves (including KLM, TKM, XM, etc.), different chipbreaking grooves are suitable for different machining conditions to meet the different needs of customers.

Applications range:

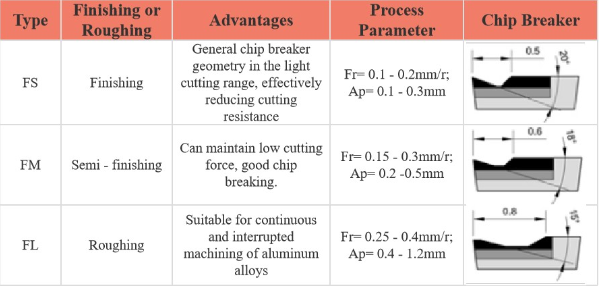

Typical groove type: