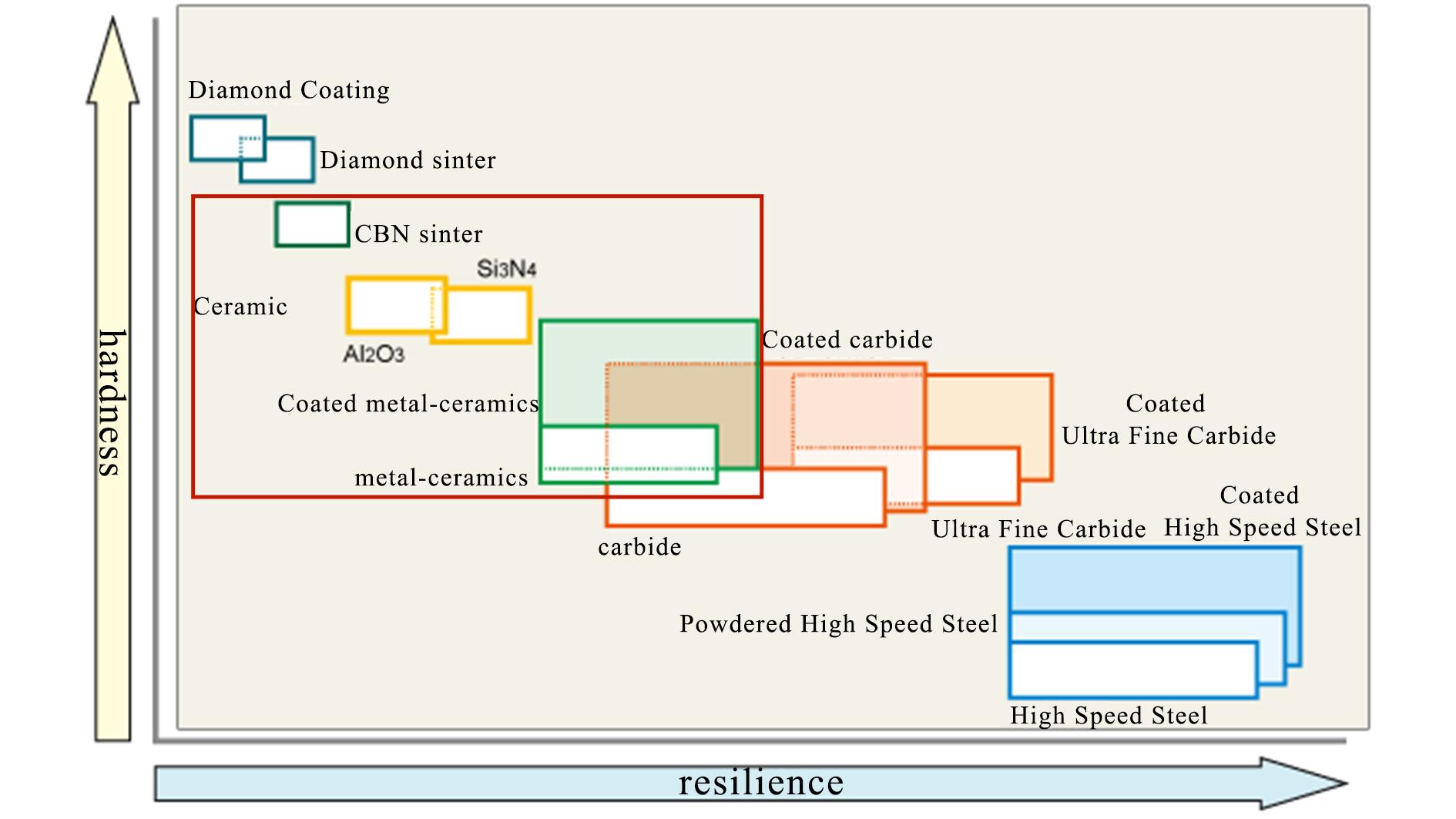

Both ceramic tools and CBN tools could provide solutions for difficult to machine materials. However, how to apply suitable tools for different applications lies in several factors. Such as, hardness, materials, cutting conditions (continuous, semi-interrupt or heavy interrupt), and machining type (turning or milling).

Although CBN belongs to the ceramic category in materials science, there is big difference between CBN, SIN, and AL2O3. The ceramic inserts are not as good as CBN inserts in toughness and hardness.

Therefore, if the working condition such as hardness less that 50HRC, small Ap and slow feed rate, ceramic inserts are better options. While CBN inserts are more suitable for hardened steel with more than HRC55 , interrupt cutting, cast iron cutting with high speed above 1000m/min, high hardness cast iron with uneven surface, rough process on cast steel, and carbide parts. Furthermore, CBN inserts are also qualified in some ceramic applications such as cast iron and hardened steel. For example, in applications of rolls and bearings, both ceramic inserts and CBN inserts could fulfill the job. But in processing brake discs, higher productivity and better surface could be achieved by CBN inserts. The customers could select suitable material according to their demands on cost and efficiency.

To sum up, there is a symbiotic relationship between CBN tools and ceramic tools to processing difficult to machine materials. Both types could be applied in a more efficiency and more precision way through their respective advantages and characteristics. With the development of technology, both types will be getting improved in their advantage sectors and provide better solutions for difficult to machine materials.