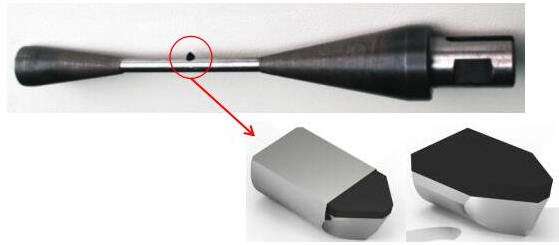

Milling hard alloy (tungsten carbide) roller ring crescent groove, also known as cutting rib, mainly uses PCD notching insert, paired with holder, as shown in the following figure:

The following is an on-site use image of PCD notching insert for millingtungsten carbide roller ring crescent grooves

PCD notching inserts can be used whether it is a newly made roller or a repair roller. PCD rnotching inserts has two structural options: welding and full face. For diameters of 4mm and above (with a maximum of 9mm), welding structure is preferred, while for diameters below 4mm, full face is mainly used. Moreover, PCD rotary engraving cutter bars can generally only use 2 milling cutters, so a new rotary engraving cutter bar needs to be replaced.

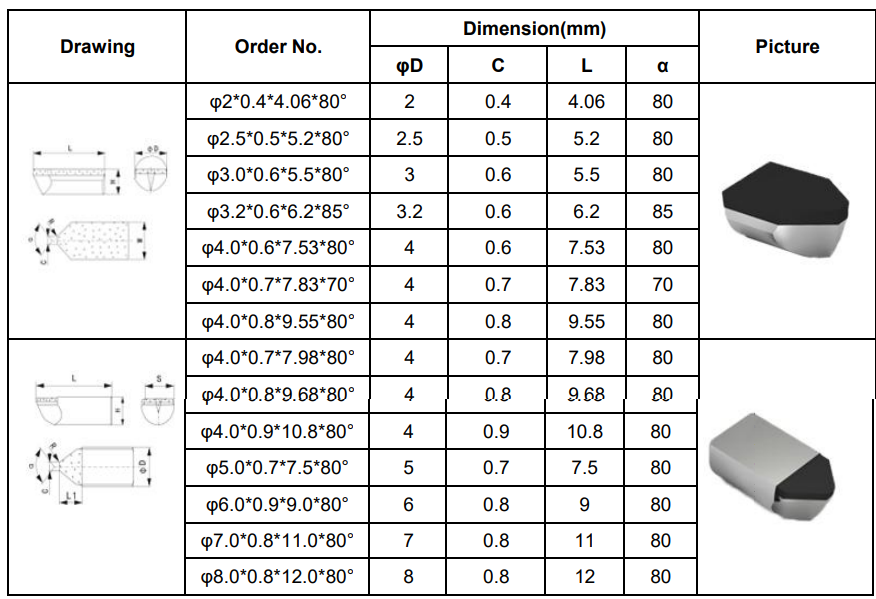

Moreover, based on years of accumulated practical experience, Halnn Superhard has summarized the specifications of PCD notching inserts required for conventional thread steel milling crescent grooves.

The following specifications of PCD notching insert are commonly used for No. 6 threaded steel: φ 2.0 * 4.0 * 0.4 * 80 °

The following specifications of PCD notching insert are commonly used for No. 8 threaded steel: φ 3.0 * 5.0 * 0.5 * 80 °

The following specifications of PCD notching insert are commonly used for No. 10 threaded steel: φ 3.0 * 6.2 * 0.6 * 80 °

The following specifications of PCD notching insert are commonly used for No. 12 threaded steel: φ 4.0 * 7.5 * 0.7 * 80 °

Note: Most of the 12 # threaded steel welding milling cutters

The cutting speed range of PCD notching insert when processing threaded steel: Fr=0.05-0.10; N=180r/min (there are differences in the speed used for different grades of rolling rolls)