PCD Notching Tools for machining Tungsten Carbide Rings

Machining the outer diameter of Tungsten Carbide Ring is relatively simple, the most difficult process for machining tungsten carbide ring is milling the grooves. Because the hardness of the tungsten carbide ring is about HRA83, when we choose the cutting tools, the hardness of the cutting tools must be higher than that of tungsten carbide rings. Superhard materials include diamond, cubic boron nitride, ceramic and Tungsten Carbide. Ceramic has high hardness(HRA91~95), good strength and good abrasive resistance, however the hardness is near to tungsten carbide, so it can’t be used for tungsten carbide. We can only choose CBN and PCD Inserts. After many times tested and long time research, we found that PCD insert is the best choice of machining tungsten carbide rings.

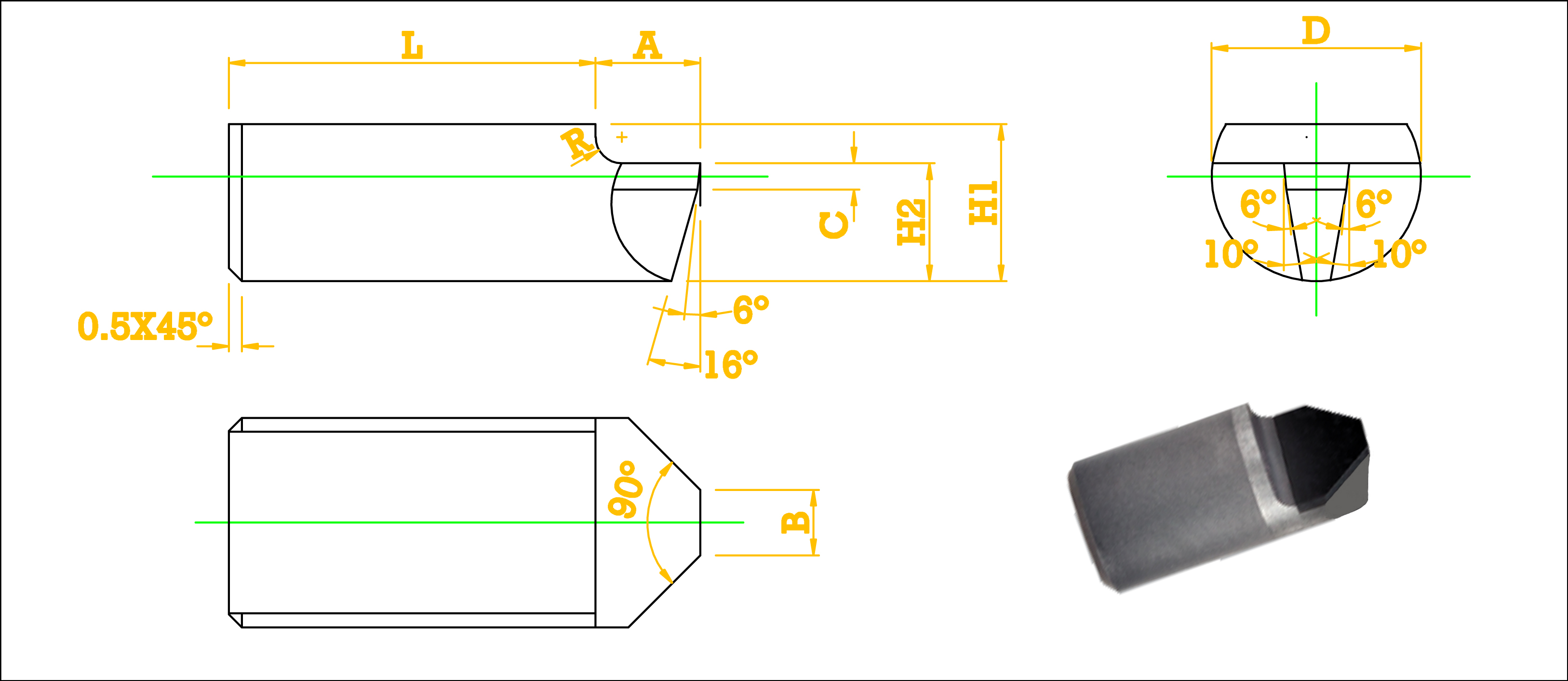

Common type of PCD Milling Insert: Indexable Brazing Milling Insert, as following image:

And common PCD materials for tungsten carbide rings as follows:

|

PCD Grade |

Granularity |

Characteristics |

Application |

|

CDW010 |

10μm |

Universal PCD Grade,Good toughness and high abrasive resistance |

Suit for single tool for rough machining, especially for wood molding, medium and low silicon alumium alloy parts(such as pistons) |

If you have any requirements or problems on PCD notching tools for machining tungsten carbide rings, please feel free to contact with us info@halnntools.com