How to judge the tool life of cbn insert ?

What circumstances cn inserts need to be replaced?

When the cbn insert is damaged, we need to change it, such as chipping,peeling, broken, cracked, and it will easily produce interrupt turning condition. When the insert dimension over the tolerance, the roughness can’t meet the drawing requirement, the insert edge appear wear phenomenon, we need to change the insert.

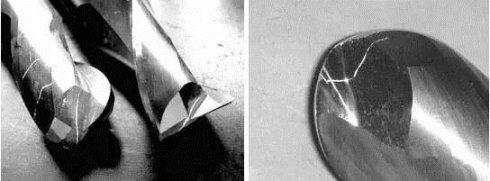

(1) Chipping

Chipping is one of the common damage type for interrupt turning steel and cast iron. It produce one or more small gaps on the cutting edge. If meet some occassion, we need to change the insert.

(2) Peeling

When milling the steel or cast iron surface, the insert rake face usually appear Shells peeled off. If appear this occassion, we can improve the cutting speed, lower the feed rate, and use the insert with negative chamfer.

(3) Broken

Broken is one common type that continuous or interrupt turning high hardness materials. The impact load is too large when interrupt turning, and will be easily broke in short time. Even though with the suitable cutting condition, but without changing the insert in time,the insert appear broke.

(4) Crack

It will easily produce crack after long time interrupt turning. When these cracks Expand continuously, the insert materials will become Fragmentation.

(5) Wear

A. Flank wear:common wear type

B. Crater wear:which occur before the rake face

C. Pressure surface wear: Caused by high cutting speed and large feed rate

D. Boundary wear:The reason is that the main corner is too big, too much feed.

When can we change the insert?

If the insert produce damage will affect the workpiece, we need to change the insert before that.

However, observe the insert frequently in the process is impossible, so machining workpiece qty will be the good choice to decide that when changing the insert, especially when the workpiece is expensive.

You can choose the cbn insert with stable performance from Halnn. As the predecessor of superhard cutting tools in China, we made brittle and hard materials as the research direction, and has advantages in heavy turning, and high speed machining field. The cbn insert grade details as follows:

|

Insert Grade |

Machining Materials |

Cutting Depth |

Condition |

|

BN-K1 |

Chilled Cast Iron, High Ni-Cr Cast Iron, High alloy cast iron |

1-10mm |

Interrupt-Continuous |

|

BN-S30 |

Cast iron, difficult to cut materials |

1-10mm |

Semi-Interrupt |

|

BN-S300 |

Gray cast iron |

≤2mm |

Continuous |

|

BNK30 |

Gray cast iron, iron series sintered alloy |

≤1.5mm |

Continuous |

|

BN-K10 |

Gray cast iron, Powder metallurgical |

≤0.5mm |

Continuous |

|

BN-S20 |

Hardened Steel, abrasive resistant and heat resistant steel, high manganese steel |

1-10mm |

Interrupt-Continuous |

|

BN-H20 |

Hardened steel, difficult to machine materials |

≤1mm |

Semi-Interrupt |

|

BN-S200 |

Hardened Steel, superalloy |

≤1mm |

Continuous |

|

BN-H11 |

Hardened Steel |

≤1mm |

Continuous |

|

BN-H10 C25 |

Hardened Steel |

≤0.5mm |

Continuous-Light Interrupt |

|

BN-H10 |

Hardened Steel,High Strength Cast Iron |

≤0.5mm |

Continuous-Light Interrupt |

|

BN-H21 |

Hardened Steel |

≤0.5mm |

Heavy Interrupt |

|

BN-H21 C25 |

Hardened Steel |

≤0.5mm |

Heavy Interrupt |