Synchronizer, as one of the most important in the gearbox, is used for buffering the speed to avoid fight teeth when change the grade.

In order to ensure the abrasive resistance of the synchronizer, the manufacturers usually use heat treatment methods to improve their performance, the hardness after quenching will be about 60HRC, and the component will easily change the size, so we need special treatment to ensure the surface and size precision.

With the development of the cutting tools industry, the main tools materials that can be used for hard turning synchronizer include carbide insert, ceramic cutters, cbn insert,ect. But because of the high hardness, only cbn can be used. Because carbide insert itself has low hardness,the component will wear more quickly, which will affect the efficiency. The ceramic cutter has large brittle, is suitable for the component with hardness below HRC55. For the workpiece with hardness about HRC60, cbn insert will be the right choice.

Halnn Superhard, as the pioneer of superhard cutting tools, has made cbn insert and diamond tools on machining brittle and hard materials as the main research direction, has enjoy high reputation in superhard academic field. And Halnn already Lead the industry first-class level on “turning instead of grinding”, high hardness heavy turning, high speed machining cast iron, and perform excellent at home and aboard.

Specific for synchronizer, Halnn recommend BN-H10 and BN-H11 CBN Material, which will be used separately for machine tools with good and bad rigidity.

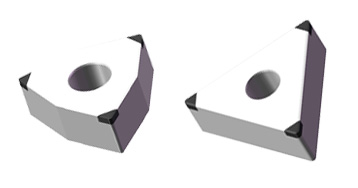

BN-H10 belong to pcbn insert, which has both excellent abrasive resistance and shockness resistance, suits for the machine tools with bad rigidity. The following is some images of BN-H10 PCBN Insert

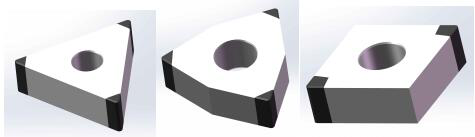

BN-H11 belongs to brazing pcbn insert, which has more cutting edges, more economic, suits for the machine tools with good rigidity. The image as follows:

One of the application case of BN-H11 hard turning synchronizer as follows:

Materials: Gear Steel

Machining Process: Hard turning

Hardness: HRC58~62

Machining Type: Dry Cutting

Insert Model:BN-H11 VNGA160404

Cutting Speeds and Feeds: Vc=170m/min, Fr=0.1mm/r,ap=0.15mm

Comparing with ceramic cutters, The performance as follows:

|

Insert Materials |

Cutting Speeds and Feeds(m/min) |

Tool Life(piece/blade) |

Failure Mode |

|

Halnn BN-H11 |

170 |

350 |

Normal Wear |

|

Ceramic Cutter |

111 |

70 |

Chipping |