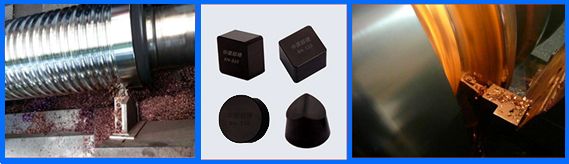

BN-S10 Solid CBN Inserts for machining HSS Rolls

As the industrial base of the most important metallurgical steel field, in the case of transformation and upgrading, casting HSS rolls and high-performance high-hardness alloy wear-resistant parts began to large amount used, especially for machining the most difficult HSS rolls. This type rolls with hardness above HRC63 required very high on the cutting tools.

BN-S10 is launched at this time, is the most suitable cutting tools for machining this type HSS Steel Rolls, and a represent ‘Made in China’, which is widely sold all over the world.

BN-S10 solid cbn inserts use non-metallic ceramic as binder, on the basis of ensure the high hardness and high wear resistance, improve the impact resistance and fracture resistance, which not only overcomes the limitation of the small size of the brazed pcbn insert, and effectively avoid the failure risk of cbn inserts. And it has obvious advantages for machining HSS Rolls

The cutting data range of machining HSS Rolls with BN-S10 solid cbn inserts as follows:

Roughing: Cutting Speed Vc = 35~120m/min, Fr=0.15~0.7mm/r, ap=1~10mm

Finishing : Ensure the size precision and the surface roughness, Vc=60~180m/min, Fr=0.05~0.35mm/r, ap≤1mm

BN-S10 belong to solid cbn insert, so both sides cutting edges can be used, and it also can be used for both roughing and finishing process, and can obey interrupted turning process, will not chip. With BN-S10 solid cbn inserts machining HSS Rolls, it not only make sure the size accuracy and the roughness requirement, and lower the production costs.