I. Introduction to Wind Turbine Gear PCBN Inserts

Definition

Polycrystalline Cubic Boron Nitride (PCBN) inserts are advanced cutting tools made from a composite material consisting of cubic boron nitride particles bonded together. PCBN is renowned for its extreme hardness, second only to diamond, making it exceptionally suitable for machining hard and abrasive materials. In the context of wind turbine gears, PCBN inserts play a crucial role in achieving the high precision and durability required for these critical components.

Importance

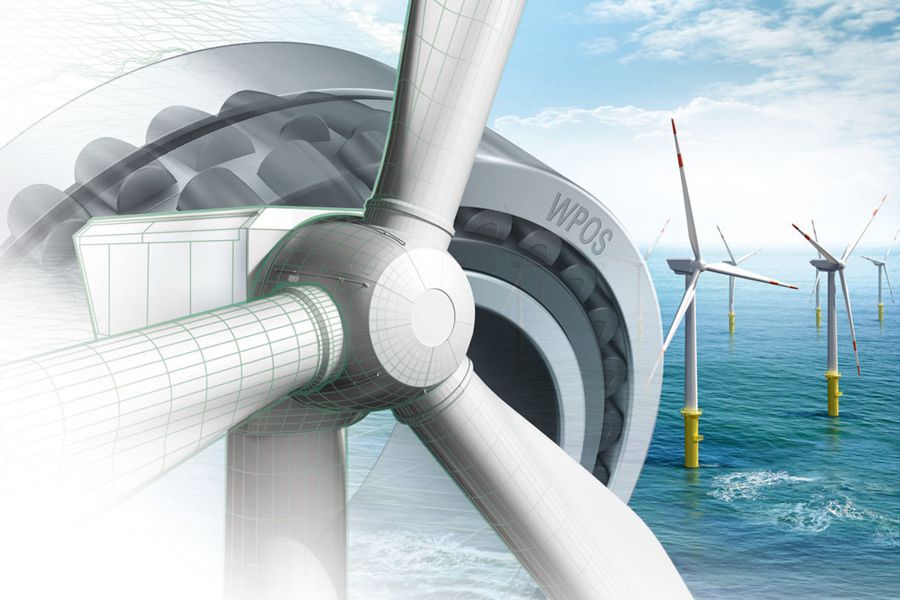

Wind turbines are complex systems that convert wind energy into mechanical energy, requiring robust and precise gears to function efficiently. The manufacturing of these gears involves machining processes that can induce high stress and wear on cutting tools. PCBN inserts provide the necessary hardness, thermal stability, and wear resistance, ensuring that wind turbine gears are manufactured with the highest quality and reliability.

II. Overview of Wind Turbine Gear Manufacturing

Manufacturing Process

The manufacturing of wind turbine gears involves several stages, including casting, forging, heat treatment, and precision machining. Each stage is crucial in ensuring the final product's strength and performance. Precision machining, in particular, is where PCBN inserts shine, providing the capability to achieve tight tolerances and superior surface finishes.

Role of PCBN Inserts

PCBN inserts are integral in the precision machining stage of gear manufacturing. They are used for turning, milling, and finishing operations on hardened steel and other tough materials. Their ability to maintain cutting performance at high temperatures and resist wear makes them indispensable in producing high-quality wind turbine gears.

III. Composition and Properties of PCBN Inserts

Material Composition

PCBN inserts are composed of cubic boron nitride particles bonded in a matrix of ceramic or metallic materials. This composite structure provides a balance of hardness and toughness, essential for cutting tools that must endure severe conditions.

Key Properties

Hardness: PCBN inserts possess exceptional hardness, allowing them to machine very hard materials without significant wear.

Thermal Stability: PCBN can withstand high temperatures generated during cutting, maintaining its hardness and performance.

Chemical Inertness: PCBN is resistant to chemical reactions with ferrous materials, reducing tool degradation.

Wear Resistance: The durability of PCBN inserts extends their tool life, reducing the frequency of tool changes and downtime.

IV. Types of PCBN Inserts for Wind Turbine Gear Machining

Tool Varieties

Turning Inserts: Used for roughing and finishing operations in turning processes.

Milling Inserts: Designed for high-speed milling of hard materials.

Boring Inserts: Utilized in precision boring to achieve tight tolerances and smooth surfaces.

Grooving and Parting Inserts: Specialized for creating grooves and parting operations on gears.

Specific Applications

Roughing: Removing large amounts of material quickly while maintaining tool integrity.

Finishing: Achieving high surface quality and precise dimensions on the gear teeth.

Profiling: Creating complex gear profiles with high accuracy.

V. Advantages of Using PCBN Inserts in Wind Turbine Gear Machining

Enhanced Performance

PCBN inserts enhance machining performance by allowing higher cutting speeds and feeds, reducing cycle times, and improving overall efficiency. Their wear resistance ensures consistent performance over longer periods.

Cost-effectiveness

Although PCBN inserts have a higher initial cost compared to conventional tools, their extended tool life and reduced downtime result in overall cost savings. Less frequent tool changes and improved machining efficiency contribute to lower production costs.

Quality Improvements

Using PCBN inserts results in higher quality gears with superior surface finishes and dimensional accuracy. This precision is critical for the performance and longevity of wind turbine gears, ensuring reliable operation in the field.

VI. Selection Criteria for Wind Turbine Gear PCBN Inserts

Material Compatibility

Choosing the right PCBN insert depends on the material being machined. For wind turbine gears, which are often made from hardened steel or other tough alloys, selecting an insert with appropriate hardness and toughness is essential.

Machining Conditions

Factors such as cutting speed, feed rate, and depth of cut must be considered when selecting PCBN inserts. The right combination of these parameters ensures optimal performance and tool life.

Economic Considerations

Evaluating the cost-effectiveness of PCBN inserts involves considering both the initial investment and the long-term savings from extended tool life and improved productivity. Halnn Group offers a range of PCBN inserts tailored to meet various budgetary and performance requirements.

VII. Best Practices for Using PCBN Inserts in Wind Turbine Gear Machining

Tool Setup and Alignment

Proper setup and alignment of PCBN inserts are crucial for achieving optimal performance. Ensuring that the inserts are correctly positioned and secured reduces the risk of tool breakage and enhances machining accuracy.

Optimizing Cutting Parameters

To maximize the benefits of PCBN inserts, it is important to optimize cutting parameters. Adjusting cutting speed, feed rate, and depth of cut to suit the specific material and machining operation helps in achieving the desired results.

Coolant and Lubrication

Effective use of coolant and lubrication is essential to maintain tool performance and longevity. Coolants help dissipate heat generated during machining, while lubricants reduce friction, preventing premature wear of the inserts.

VIII. Maintenance and Care of PCBN Inserts

Routine Maintenance

Regular maintenance of PCBN inserts includes cleaning to remove built-up material and inspecting for signs of wear or damage. Keeping the inserts in good condition ensures consistent performance and extends their service life.

Tool Sharpening and Reconditioning

When PCBN inserts become dull, they can often be reconditioned through professional sharpening services. This process restores their cutting edge, allowing them to perform as effectively as new inserts.

Storage and Handling

Proper storage and handling of PCBN inserts prevent damage and contamination. Keeping inserts in a clean, dry environment and handling them with care prolongs their usability and performance.

IX. Innovations and Advancements in PCBN Tool Technology

Material and Coating Innovations

Recent advancements in PCBN material compositions and coatings have further enhanced the performance and durability of these inserts. New formulations provide even greater wear resistance and thermal stability.

Technological Developments

Innovative technologies, such as advanced CNC machining, automation, and tool monitoring systems, have improved the efficiency and accuracy of machining processes using PCBN inserts.

Future Trends

Future trends in PCBN tool technology include the development of even harder and more wear-resistant materials, as well as enhanced coatings that provide additional protection and performance benefits.

X. Conclusion

PCBN inserts are essential tools for machining wind turbine gears, offering exceptional hardness, thermal stability, and wear resistance. They improve machining efficiency, reduce costs, and enhance gear quality.

Explore Halnn Group's range of PCBN inserts tailored for wind turbine gear machining. Contact our experts for personalized advice and discover how our advanced cutting tools can transform your manufacturing processes.

XII. FAQs of Wind Turbine Gear PCBN Inserts

Q: What are the benefits of using PCBN inserts for wind turbine gear machining?

A: PCBN inserts offer superior hardness, wear resistance, and thermal stability, resulting in improved machining efficiency, longer tool life, and higher quality gears.

Q: Can PCBN inserts be reconditioned?

A: Yes, PCBN inserts can often be reconditioned through professional sharpening services, restoring their cutting edge and extending their service life.

Q: What are PCBN inserts made of?

A: PCBN inserts are made of cubic boron nitride particles bonded together in a matrix.

Q: Why are PCBN inserts preferred for wind turbine gear machining?

A: PCBN inserts offer superior hardness, wear resistance, and thermal stability, making them ideal for high-precision and high-efficiency machining of wind turbine gears.

Q: Can PCBN inserts be used for all materials?

A: PCBN inserts are best suited for machining hard and abrasive materials like hardened steels and cast irons.

Q: How do I select the right PCBN insert for my application?

A: Selection depends on factors like the material of the gears, machining conditions (cutting speed, feed rate, depth of cut), and economic considerations. Consulting with tool manufacturers or experts can help in making the best choice.

Q: How often should PCBN inserts be maintained?

A: Routine maintenance, including cleaning, inspection, and occasional reconditioning, is essential to maintain the performance and extend the life of PCBN inserts.