As a National High-tech Enterprise, a leading manufacturer of superhard materials and products in Henan Province, Halnn Group serves 80% of the equipment manufacturing industry and Fortune 500 enterprises globally. Under continuous innovation, great advantages were established in certain segment markets by the core production series of PCBN/PCD tools.

1、Heavy dutyTM Series PCBN inserts

First, ceramic bond is adopted instead of metal ones, which make the tools is suitable for the heavy-duty working conditions such as longer processing time, greater cutting force, and higher cutting temperature. Second, Mo is adopted instead of carbon as the synthetic mold under high-temperature and high-pressure conditions, which makes the base denser; Third, the cutting-edge passivation was optimized. All above developments get Halnn great advantages to compete with world famous brands and gain market shares overseas.

2、LengthenTM Series PCBN inserts

Halnn advantages of LengthenTM series PCBN inserts are follows, First, the length of edge could be 4mm, by which heavy-duty hard turning with AP1.5mm could be achieved; Second, higher efficiency could be achieved by using the same insert on both semi-finish and finish processing; Third, a special treatment was applied on the edge, which makes it much stronger and stable. Then, more strict requirements on precision could be achieved.

Halnn advantages of LengthenTM series PCBN inserts are follows, First, the length of edge could be 4mm, by which heavy-duty hard turning with AP1.5mm could be achieved; Second, higher efficiency could be achieved by using the same insert on both semi-finish and finish processing; Third, a special treatment was applied on the edge, which makes it much stronger and stable. Then, more strict requirements on precision could be achieved.

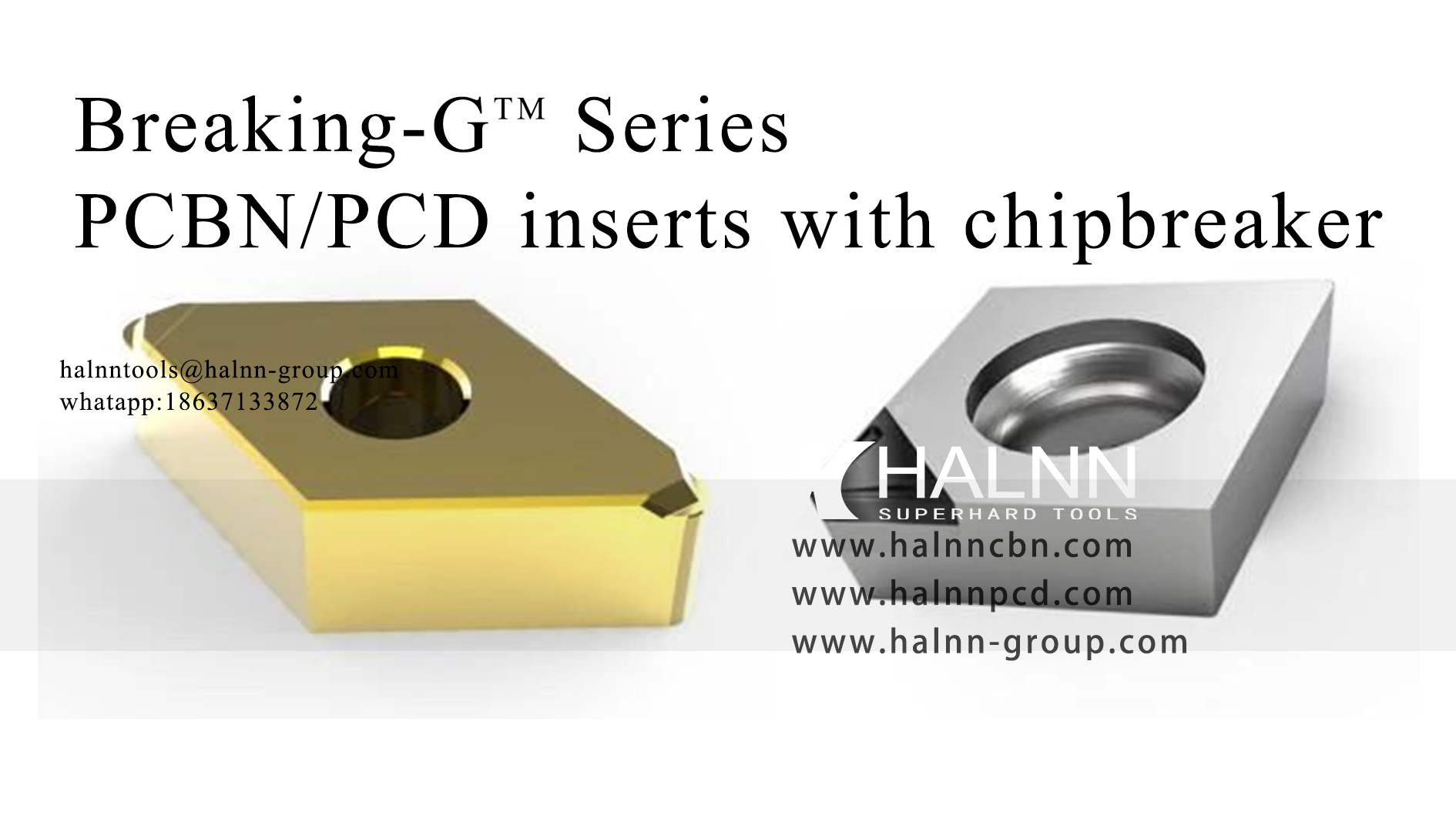

3、Breaking-GTM Series PCBN/PCD inserts with chipbreaker

PCBN/PCD Inserts in Breaking-GTM series are with chip-breakers which can solve the problems cased by chips. PCBN chip breaker insert is prepared by ultra-precision grinding machine. With more stable performance, smooth surface, and avoiding white layer, higher surface quality could be guaranteed.

PCBN/PCD Inserts in Breaking-GTM series are with chip-breakers which can solve the problems cased by chips. PCBN chip breaker insert is prepared by ultra-precision grinding machine. With more stable performance, smooth surface, and avoiding white layer, higher surface quality could be guaranteed.

4、WiperTM Series CBN insert

In WiperTM series are CBN inserts with wipers, which are suitable for lathes and workpieces with high rigidity. Higher surface quality could be achieved under same feed rate, or higher feed rate under same requirement of Ra.

5、Fix-STM Series CBN Insert with Positioning Pit

CBN Insert with Positioning Pit in Fix-STM series are mainly in solid CBN structure. The design of fix-bore is convenient for clamping. It is especially suitable for contour machining and speed cutting.

6、Full Face PCBN/PCD Insert Series

Full Face PCBN/PCD Insert series are with fine abrasive resistance. The multiple edges make the production cost being reduced. Meanwhile, being equipped with high rigidity holders and under higher feed rate and cutting speed, the inserts could achieve high efficiency and stable machining.

7、PCD High Finish Series

PCD High Finish Series are mainly apply to mirror-surface polishing on mold steel. Ultra surface quality could be achieved.

8、PCD Milling Inserts Repairment Service

The repairment service for PCD milling inserts is also provided by Halnn. The used inserts could be refreshed as new ones after repair. In this way, resources consumption could be reduced.