1. Types of Halnn PCD cutting tools

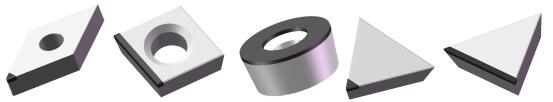

(1) PCD inserts: mainly used for turning, milling, boring, chamfering, etc.

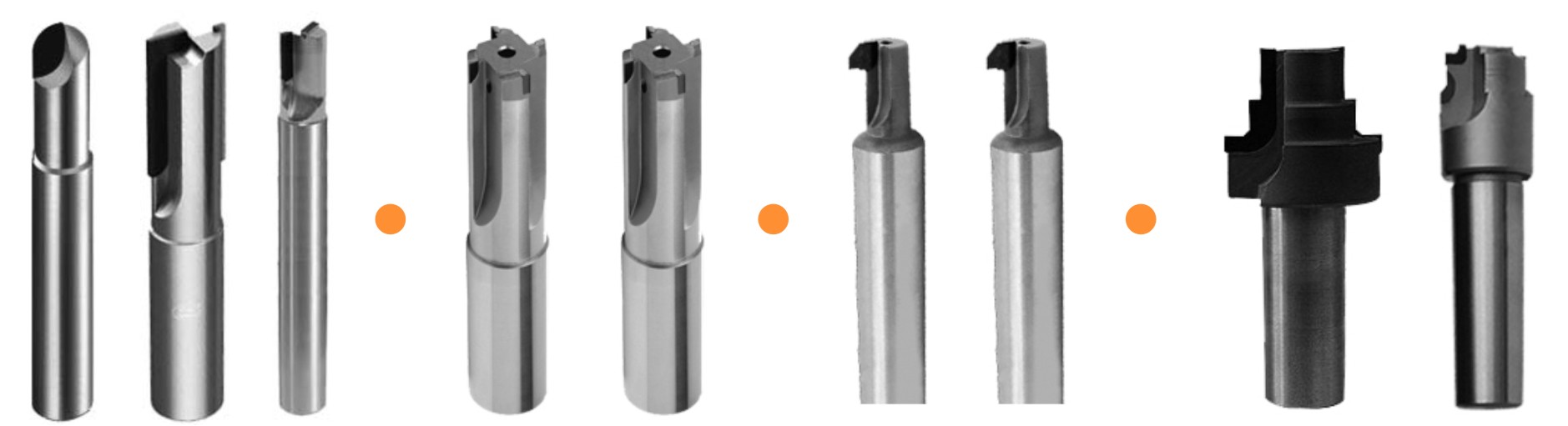

(2) PCD milling cutter: one or more PCD cutting edges are welded on the alloy or high-speed steel cutter base, mainly used for milling planes, steps, bosses, etc.

(3) PCD reamer: Generally, according to the diameter, an alloy matrix or a steel matrix is used, and the number of cutting edges is 2 or more. It is mainly used for holes with strict machining tolerances and high smoothness requirements, blind through holes Holes can be machined. Using Halnn PCD reamer, the smoothness of the hole can reach within Ra0.1.

(4) PCD boring tool: It is mainly used in through holes or blind holes with high requirements for smoothness and strict shape and position tolerances. Among them, the welded structure, the general hole diameter is not less than φ3.5 Halnn can be processed.

(5) PCD forming tool: It belongs to the rotary tool, which can mill multiple stepped holes at the same time, with high processing efficiency and relatively accurate shape and position tolerance.

2. Application of Halnn PCD cutting tools

(1) Processing material

Non-ferrous metal materials and their alloys: such as aluminum alloy, magnesium aluminum alloy, silicon aluminum alloy, copper alloy, red copper, brass, tungsten carbide hard alloy, ceramics, and other materials, the material of the above material workpiece Halnn PCD blade CDW010 can be processed, For alloy materials that require higher wear resistance, coarse-grained and mixed-grained PCD material tools CDW025 and CDW302 can be selected.

Non-metallic materials: such as composite materials, carbon fiber, glass fiber, graphite, wood, stone, polyurethane rubber, glass, reinforced plastics, etc. PCD blades CDW002, CDW010, CDW025, and CDW302 are more wear-resistant than alloy blades for processing parts of such materials, longer life, and higher efficiency.

(2) Application field