1. Composite materials

The so-called composite material is a multi-phase material composed of two or more component materials with different properties and different states through a composite process. Due to the characteristics of light weight, high strength, convenient processing and molding, excellent elasticity, chemical corrosion resistance, and good weather resistance, composite materials have gradually replaced wood and metal alloys, and are widely used in aerospace, automobiles, electrical, and electronics, construction, and fitness equipment, and other fields.

For composite materials, Halnn Superhard recommends diamond-coated tools and PCD tools, which can achieve efficient machining and precision cutting.

(1) Halnn superhard diamond-coated cutting tools directly deposit diamond film on the substrate, which greatly improves the wear resistance of the cutting edge. The geometric structure of the original tool ensures the processing effect.

(2) PCD tools are ideal tools for processing composite materials at present. The hardness of PCD is as high as 8000HV. Halnn Superhard uses imported high-quality PCD sheets. At the same time, PCD milling cutters and PCD drills can be designed with internal cooling (internal spiral cooling) channels Improved cooling performance, helical flutes for drills, and helical milling cutters improve chip evacuation, which in turn increases machining efficiency.

2. Aluminum and aluminum alloy

Aluminum is a metal with low strength and good plasticity. In addition to the application of some pure aluminum, in order to improve the strength or comprehensive performance, it is made into an alloy. Adding an alloying element to aluminum can change its structure and properties, making it suitable for various processing materials or casting parts. Alloying elements that are often added are copper, magnesium, zinc, silicon, manganese, etc. At present, it has been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, and the chemical industry.

Halnn Superhard recommends PCD chip breaker inserts and PCD milling cutters for the precision cutting of aluminum and aluminum alloys.

1. Halnn superhard PCD chip breaker inserts can achieve outstanding chip-breaking effects in aluminum alloy finishing-semi-finishing, greatly improve operation efficiency, realize stable processing, and ensure long tool life.

2. Halnn superhard PCD milling cutter has the advantages of high wear resistance and high processing efficiency. The high-speed milling speed of the Halnn superhard milling insert can reach 3000m/min and has excellent processing performance.

3. For high-gloss effect requirements, single-crystal diamond tools can be selected for processing.

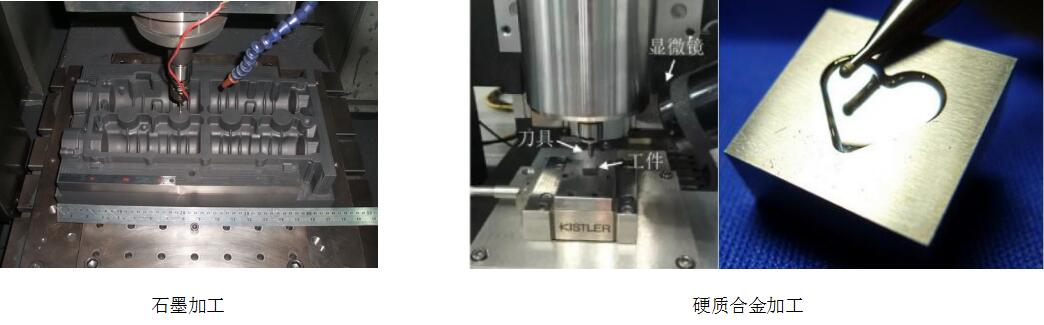

3. Expanded applications in graphite, cemented carbide, ceramics, and other fields

In addition to being widely used in composite materials and aluminum and aluminum alloys, Halnn superhard diamond tools can also process copper and copper alloys, titanium alloys, reinforced plastics, graphite, hard alloys, ceramics, and other materials.

Among them, processing graphite, ceramics, and hard alloys can choose Halnn superhard PCD milling cutters, single crystal diamond cutters, and diamond-coated cutters.