As a key component of the automobile braking system, the brake disc is a powerful guarantee for the safe driving of the automobile and is closely related to people's production and life. There are many types of brake discs, and they are thin-walled gray iron castings, which have high technical requirements. Different types of brake discs have differences in disc diameter, disc thickness and gap between two discs, and the thickness and height of disc hubs are also different. All the outer contours of the brake discs need to be processed, and after finishing, there must be no casting defects such as shrinkage porosity, air holes, sand holes, etc., and the requirements for flatness and precision are high.

Because when the tool material has a high affinity with the metal molecules of the processed material, the processed material is easy to bond with the tool to form built-up edges and scales, Therefore, if the adhesion is serious and the friction is serious, the surface roughness will be large, and vice versa.

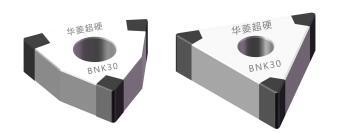

In the same process of processing brake discs, it is difficult for cemented carbide tools to meet the surface roughness requirements of Ra1.6. Even if it is achieved, the tool's life will be greatly reduced. In this regard, the BNK30 brand CBN cutter developed by Valin Superhard has a low friction coefficient due to the cutter material. Due to its excellent high-temperature thermal stability and wear resistance, the surface roughness of Ra1.6 can be easily processed under the condition that the cutting speed is several times higher than that of cemented carbide, and the tool life is dozens of times that of carbide tools, and also Surface brightness increased by an order of magnitude.

Halnn tools has launched two cutting tools for brake discs: BN-S300 brand integral polycrystalline cubic boron nitride cutter and BNK30 brand through-welding cubic boron nitride cutter, which are used for rough machining and finishing processes respectively. Valin Superhard BN-S300 brand overall polycrystalline cubic boron nitride tool is a bulk material sintered by CBN micro-powder without alloy substrate. Because of the use of non-metal as binder, it has excellent high-temperature red hardness and large margin for turning brake discs. Blades do not splinter, do not burn.

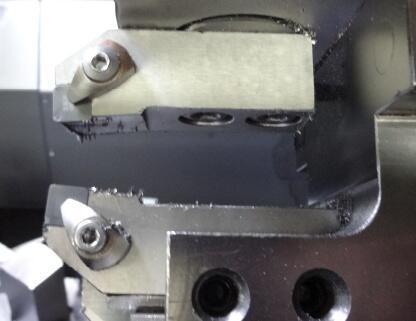

At the same time, Halnn can provide combined cutting tools (two-knife and two-sided simultaneous processing) according to different machine tool lines to ensure the parallelism of the upper and lower planes.

(1) When using a horizontal lathe to process the brake disc, the flatness and parallelism of the brake disc are ensured by simultaneous feeding of two knives and two sides, and the processing efficiency is twice that of processing the front and back sides sequentially.

(2) When using the vertical lathe to process brake discs, one side and two inserts are used for simultaneous processing, which greatly improves the efficiency and flatness.

The two methods are set according to the needs of different assembly lines and the model and quantity of machine tools. In comparison, due to the good rigidity and the large resection area per unit time that can be tolerated during vertical lathe processing, the efficiency will be higher. For the horizontal lathe, the change of the tool table is small, so it is easier to make and put into production the combined tool with double-knife and double-side feed immediately. It should be noted that when processing the brake disc with double-knife and double-side feed The two turning tools feed from the left and right sides at the same time, which increases the risk of vibration. Therefore, when using this double-sided feeding structure, try to use an insert with an arc angle of R0.4.