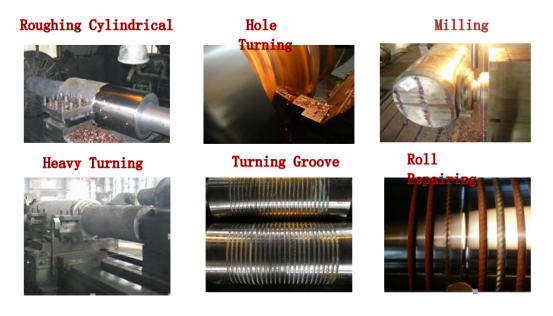

Halnn has very rich experience in processing various material Rolls, and can provide a series of complete processing tools and technical support for all customers. With the background of Henan Research Institute of superhard material, we have a strong technical team. Up to now, more than 60% of roll manufacturers are using our tools to process rolls in China. And our Rolls special tools are sold well in North America, South America, Europe, Southeast Asia, and many other countries and regions.

Materials of Rolls:

Tungsten Carbide

High Speed Steel, High Boron Steel, High Carton Steel, Forging steel 9Cr2Mo, and so on

High Hardness Cast Iron, High Chromium Cast Iron, High Chrome Nickel Cast Iron, SG Cast Iron,

Chilled Cast Iron and so on.

Recommend inserts:

Solid CBN Inserts, Full Face solid CBN Inserts, Carbide Notching Tools, PCD Notching Tools, PCD

Engraving Tools

Process Condition:

Roughing, Finishing; Continuous, Light Interrupt, Heavy Interrupt

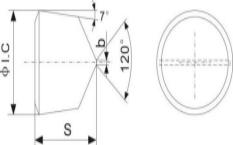

Solid CBN Inserts

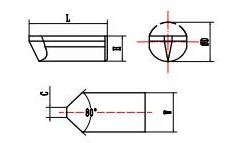

Drawing | Type | Dimension | Picture |

L(mm) | φI.C(mm) | S(mm) | b(mm) |

| RCMX060400V |

| 6.35 | 4.76 | 0.8 |  |

RCMX060500V |

| 6.35 | 5.56 | 0.8 |

RCMX060600V |

| 6.35 | 6.35 | 0.8 |

RCMX090700V |

| 9.525 | 7.94 | 1 |

RCMX120700V |

| 12.7 | 7.94 | 2 |

RCMX151000V |

| 15.875 | 10 | 2 |

RCMX191000V |

| 19.05 | 10 | 2 |

RCMX201200V |

| 20 | 12 | 2 |

RCMX251200V |

| 25.4 | 12 | 2 |

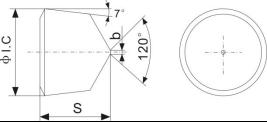

Drawing | Type | Dimension | Picture |

L(mm) | φI.C(mm) | S(mm) | b(mm) |

| RCMX060400Y |

| 6.35 | 4.76 |

|

|

RCMX060500Y |

| 6.35 | 5.56 |

|

RCMX060600Y |

| 6.35 | 6.35 |

|

RCMX060700Y |

| 6.35 | 7.94 |

|

RCMX090700Y |

| 9.525 | 7.94 |

|

RCMX120700Y |

| 12.7 | 7.94 |

|

RCMX151000Y |

| 15.875 | 10 |

|

RCMX191000Y |

| 19.05 | 10 |

|

RCMX201200Y |

| 20 | 12 |

|

RCMX251200Y |

| 25.4 | 12 |

|

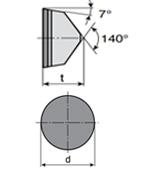

PCBN / PCD Tools - RCGX V / Y type

Drawing | Type | Dimension | Picture |

L(mm) | φd(mm) | t(mm) | b(mm) |

| RCGX060300 V / Y |

| 6.35 | 3.18 |

|  |

RCGX060400 V / Y |

| 6.35 | 4.76 |

|

RCGX060500 V / Y |

| 6.35 | 5.56 |

|

RCGX060600 V / Y |

| 6.35 | 6.35 |

|

RCGX090300 V / Y |

| 9.525 | 3.18 |

|

RCGX090700 V / Y |

| 9.525 | 7.94 |

|

RCGX120400 V / Y |

| 12.7 | 4.76 |

|

RCGX120700 V / Y |

| 12.7 | 7.94 |

|

RCGX151000 V / Y |

| 15.875 | 10 |

|

RCGX191000 V / Y |

| 19.05 | 10 |

|

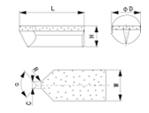

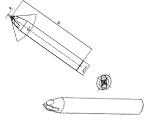

CBN / PCD Notching Tools

Drawing | Order No. | Dimension(mm) | Picture |

φD | C | L | α |

| φ2*0.4*4.06*80° | 2 | 0.4 | 4.06 | 80 |  |

φ2.5*0.5*5.2*80° | 2.5 | 0.5 | 5.2 | 80 |

φ3.0*0.6*5.5*80° | 3 | 0.6 | 5.5 | 80 |

φ3.2*0.6*6.2*85° | 3.2 | 0.6 | 6.2 | 85 |

φ4.0*0.6*7.53*80° | 4 | 0.6 | 7.53 | 80 |

φ4.0*0.7*7.83*70° | 4 | 0.7 | 7.83 | 70 |

φ4.0*0.8*9.55*80° | 4 | 0.8 | 9.55 | 80 |

| φ4.0*0.7*7.98*80° | 4 | 0.7 | 7.98 | 80 |  |

φ4.0*0.8*9.68*80° | 4 | 0.8 | 9.68 | 80 |

φ4.0*0.9*10.8*80° | 4 | 0.9 | 10.8 | 80 |

φ5.0*0.7*7.5*80° | 5 | 0.7 | 7.5 | 80 |

φ6.0*0.9*9.0*80° | 6 | 0.8 | 9 | 80 |

φ7.0*0.8*11.0*80° | 7 | 0.8 | 11 | 80 |

φ8.0*0.8*12.0*80° | 8 | 0.8 | 12 | 80 |

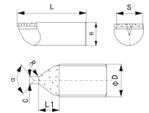

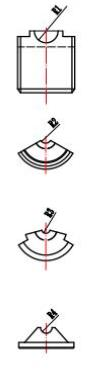

Carbide Notching Tools

Drawing | Order No. | Dimension(mm) |

φD | H | W | L | C |

| HL-2.0 | 2 | 1.5 | 1.3 | 3.9 | 0.4 |

HL-2.5 | 2.5 | 1.9 | 1.6 | 4 | 0.5 |

HL-3.0 | 3 | 2.3 | 2 | 5 | 0.5 |

HL-4.0 | 4 | 3 | 2.6 | 6.5 | 0.7 |

HL-5.0 | 5 | 3.8 | 3.3 | 7.5 | 0.7 |

HL-6.0 | 6 | 4.5 | 4 | 9 | 0.8 |

HL-8.0 | 8 | 5.6 | 5.1 | 12 | 0.8 |

HL-10.0 | 10 | 7.2 | 6.7 | 15.2 | 1 |

Drawing | Order No. | Dimension(mm) |

φD | H | W | L | C |

| HL-2.0 | 2 | 1.3 | 1.8 | 3.9 | 0.4 |

HL-2.5 | 2.5 | 1.6 | 2.3 | 4.0 | 0.5 |

HL-3.0 | 3 | 2.0 | 2.7 | 5.0 | 0.5 |

HL-4.0 | 4 | 2.6 | 3.6 | 6.5 | 0.7 |

HL-5.0 | 5 | 3.3 | 4.5 | 7.5 | 0.7 |

HL-6.0 | 6 | 4.0 | 5.4 | 9.0 | 0.8 |

HL-8.0 | 8 | 5.1 | 7.2 | 12.0 | 0.8 |

HL-10.0 | 10 | 6.7 | 9.0 | 15.2 | 1.0 |

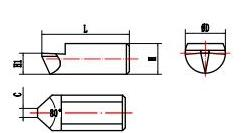

PCD Engraving Tools

Drawing | Order No. | Shank D/d1h7 | Length/ L | Angle/Er | Width/B | Picture |

| φ6.0*50*70°*0.3 | 6 | 50 | 70 | 0.3 |  |

φ6.0*50*70°*0.5 | 6 | 50 | 70 | 0.5 |

φ6.0*50*70°*0.5 | 6 | 50 | 90 | 0.3 |

φ6.0*50*90°*0.5 | 6 | 50 | 90 | 0.5 |

φ8.0*50*70°*0.3 | 8 | 50 | 70 | 0.3 |

φ8.0*50*70°*0.5 | 8 | 50 | 70 | 0.5 |

φ8.0*50*90°*0.3 | 8 | 50 | 90 | 0.3 |

φ8.0*50*90°*0.5 | 8 | 50 | 90 | 0.5 |

Block

Drawing | Type | R1 | R2 | R3 | R4 | Picture |

| 6# | 1.9 | 1.8 | 1.9 | 1.8 |  |

8# | 2.5 | 2.25 | 2.5 | 2.25 |

10# | 3 | 3 | 3 | 3.1 |

12# | 3.75 | 3.8 | 3.5 | 4.3 |

14# | 4.5 | 4.5 | 4.5 | 4.3 |

16# | 5 | 5.05 | 5 | 5.05 |

18# | 6 | 6 | 6 | 6 |

20# | 6.9 | 6.9 | 6.9 | 6.9 |

22# | 7.6 | 7.6 | 7.6 | 7.6 |

25# | 8.8 | 8.8 | 8.8 | 9 |

28# | 10.15 | 10.15 | 10.15 | 10.15 |

32# | 11.6 | 11.6 | 11.6 | 11.6 |

36# | 13.15 | 13 | 13.15 | 13.15 |

40# | 14.5 | 14.5 | 14.5 | 14.5 |

50# | 18.6 | 18.6 | 18.6 | 18.6 |