Problems of difficult machining of bearings: (1) The hardness after heat treatment is high, reaching about HRC55, especially for large bearings, the deformation is large, and the traditional tools life cannot meet customer needs (3) The bearing requires high precision, and the efficiency of the grinding process is too low, which affects Productivity.

The working environment of the bearing is harsh, so requires the workpiece performance is to be high, and high precision is required. Therefore, Halnn Superhard recommends to use CBN tools. According to different machining allowances, CBN tool types with different structures are selected.

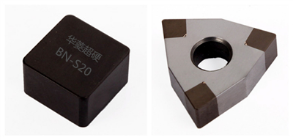

The metallurgical bearing size is relatively small, the machining allowance is generally within 0.5mm. In this case, it is suitable to choose a brazed CBN tool to finish. Halnn Superhard recommends BN-H11 grade CBN inserts, the roughness can achieve within Ra0.8.

For example, the wind power bearing size is relatively large, the accuracy is strict, the allowance is generally 2-6mm, and the deformation is large. In this case, it is suitable to choose solid CBN tools to process, which can reduce the number of tool passes and improve production efficiency. Halnn Superhard recommends BN-S20 grade CBN inserts, cutting depth can achieve 4mm.