Advantage of Halnn BN-S20 grade CBN tools for machining Roll

As an important part of the rolling mill, the performance of the mill determines the quality of the rolled material andthe efficiency

of the rolling mill. Therefore, the roll generally has high hardness, especially for large casting rolls.There are casting defects

such as sand and pores on the surface, which requires high hardness cutting tools. It is required to have high wear resistance

and also to meet impact toughness and fracture resistance. Halnn superhard,has been researching and developing cutting tools

for brittle hard materials in the early stage. For the roll industry,Halnn has developed two CBN tool materials - BN-K1 grade CBN

tools and BN-S20 grade CBN tools, with special bonding agents to improve heat resistance ensures a more stable cutting

process,and it does not collapse when it encounters casting defects, does not break, and greatly reduces cost and efficiency.

Ⅰ,Cast iron rolls

The difficult of machining cast iron rolls is that there are casting defects on the surface, the margin is large. It is recommended to

use the BN-K1 grade CBN tools, which can increase the processing efficiency and reduce the production cost. The case is as follows:

Halnn BN-K1 grade CBN tool for machining Cast iron rolls

|

|

Roll material: nickel-chromium alloy cast iron

Roll hardness: HSD80

Tool type: BN-K1 RNMN200800

Cutting parameters: ap=4mm;

Fr=1mm/r;

Vc=55m/min

Processing method: dry cutting

|

Tool materials

|

Feed rate(Fr)

|

Tool life

|

Halnn BN-K1grade CBN tool

|

1mm/r

|

3pcs/edge

|

A European brand ceramic tool

|

0.5mm/r

|

0.5pcs/edge

|

Ⅱ,High speed steel rolls

With the transformation and upgrading of the steel industry, casting high-speed steel rolls, high-performance high-hardness alloy

wear parts began to be widely used, especially in the case of composite high-speed steel rolls, Through technical innovation,

Halnn CBN tool is unique in superhard machining of high speed steel roll and other fields. For the high-speed steel roll Halnn

recommended BN-S20 grade CBN tool, not only has excellent high temperature red hardness, but also excellent wear resistance,

is the best of choice CBN tool for machining high speed steel rolls. The case is as follows:

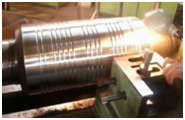

Halnn BN-S20 grade CBN tool for machining High speed steel rolls

|

|

Roll material: high speed steel

Roll hardness: HSD90

Tool type: BN-S20 RCMX120700

Cutting parameters: Fr=0.2mm/r, Vc=50m/min

Processing method: dry cutting

|

Tool materials

|

Processing beat

|

Tool life

|

Halnn BN-S20 grade CBN tool

|

2h

|

25 slot/edge

|

A brand of carbide tool

|

12h

|

3 slot/edge

|

Ⅲ, Surfacing rolls/Spray welding rolls

Many rolls are expensive because they are often repaired by surfacing/spray welding after failure, and then turned to restore

size and surface quality.

The surface of the roll after surfacing is irregular, and the fracture resistance of the cutting tool is high. Halnn recommends

the BN-S20 grade CBN tool, and its processing effect is significantly improved. The case is as follows:

|

Halnn BN-S20 grade CBN tool for machining Surfacing rolls/Spray welding rolls |

|

Repair process: surfacing

Roll diameter: 240

Blade model: BN-S20 SNMN120712

Tool holder type: CSRNR2525M1207

Cutting parameters: N=45, Fr=0.16mm/r, ap=2mm |

|

Machining effect: The tool has no chipping or severe wear, the tool life is long, the production efficiency is improved, and the product quality is guaranteed. |