There are many types of hardened steel parts. In the face of different workpieces, only the correct cutting tools can be selected

to solve the problem better and more effectively, and improve the processing efficiency. Halnn developed different CBN tools for

different hardened steel parts. The specific grades are as follows:

|

Insert Model |

Processing Condition |

Depth of Cut(mm) |

Machining Type |

Machining Hardness |

Insert Image |

|

BN-S20 |

Roughing/Semi-finishing |

0.5~10 |

Intermittent cutting/Continuous cutting |

HRC45~68 |

|

|

BN-S200 |

Fine Finishing |

≤1 |

Continuous turning |

HRC45~68 |

|

|

BN-H21 |

Fine Finishing |

≤0.5 |

Heavy interrupted turning/Continuous cutting |

HRC62~68 |

|

|

BN-H10 |

Fine Finishing |

≤0.3 |

Continuous cutting |

HRC45~68 |

|

|

BN-H20 |

Fine Finishing |

≤1 |

Intermittent cutting/Continuous cutting |

HRC45~63 |

|

|

BN-H11 |

Fine Finishing |

≤1 |

Continuous cutting |

HRC45~63 |

|

Halnn CBN tools hard turning hardened steel gear case

(1) Continuous cutting conditions: Halnn CBN tools BN-H10 and BN-H11 grade are selected, high speed cutting, good wear

resistance and fracture resistance, mainly used in finishing process, the case is as follows:

Hard turning hardened steel parts—gear

|

|

Processing parts: Gear (Semi-interrupted cutting)

Workpiece material: Hardened steel(HRC58-62)

Machining process: Finish turning after quenching

Tools type: BN-H10 CNGA120408S01020

Cutting parameters: Cutting speed(Vc)=180m/min,

Feed rate(Fr)=0.1mm/r,

Cutting depth(ap)=0.2mm

Processing method: dry cutting

|

Tool material

|

Cuttingspeed(Vc)m/min |

Tool life pcs/edge

|

Production beat s/pcs

|

|

Halnn BN-H10 |

180m/min |

800 |

6s |

a European ceramic tools

|

130m/min |

150 |

8.5s |

(2) Intermittent cutting: Select Halnn CBN tools BN-H20 and BN-H21 grade, which not only has high hardness, good wear

resistance, but also good fracture resistance. The gear end face of the machined hole does not collapse, the case is as follows :

Hard turning hardened steel parts—gear

|

|

processing parts: Gear (Continuous cutting)

Workpiece material: Hardened steel(HRC58-63)

Machining process: Finish turning after quenching

Tools type: BN-H20 WNGA080408S01020

Cutting parameters: Cutting speed(Vc)=120m/min,

Feed rate(Fr)=0.1mm/r,

Cutting depth(ap)=0.25mm

Processing method: dry cutting

|

Tool material

|

Cuttingspeed(Vc)m/min |

Tool life pcs/edge

|

Tool cost

|

|

Halnn BN-H20 |

120m/min |

700 |

Save 50%

|

a European ceramic tools

|

120m/min |

650 |

--- |

(3) Heavy interrupted cutting: cutting edge interrupt contact with the workpiece, such as machining gear tooth surface, high

hardness and difficult to process, Halnn CBN tools BN-S20 grade is a non-metallic adhesive CBN tool, not only high hardness,

resistance abrasive and impact resistance, and intermittent cutting of the workpiece does not collapse, the cutting depth can

be adjusted according to the rigidity of the machine tool, the processing results are as follows:

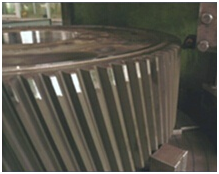

Hard turning hardened steel parts—gear

|

|

processing parts: Big gear (Heavy interrupted cutting)

Workpiece hardness: HRC60

Machining process: Finish turning outer circle

Tools type: BN-S20 SNGN120712

Cutting parameters: Cutting speed(Vc)=90m/min,

Feed rate(Fr)=0.12mm/r,

Cutting depth(ap)= 2.5mm

Processing method: dry cutting

|

Tool material

|

Cuttingspeed(Vc)m/min |

Tool life pcs/edge

|

Failure form

|

|

Halnn BN-S20 |

90m/min |

5 |

Normal abrasion

|

a brand of ceramic tools

|

45m/min |

0.3 |

Collapse

|

In addition to the above components, Halnn CBN tools can also hard turning hardened steel molds, universal joints, synchronizer

sleeves and other components: hard turning hardened steel molds, CBN tools BN-S200 finish milling molds, CBN tools BN-H10

grade can be selected for the turning hardened steel universal joint. The CBN tools BN-H20 is recommended for the hard turning

synchronizer sleeve.