With the increasing competition in the auto parts industry and the rising prices of raw materials, in order to ensure their own

competitive advantages, auto manufacturers are gradually adopting CNC machine tool production to ensure the improvement

of production efficiency and the reduction of total cost.

In order to meet the needs of cost reduction and efficiency improvement in the auto parts industry, the cutting tool industry

continues to innovate. Among them, Halnn is a pioneer in China of superhard tools, and has successfully developed a variety

of CBN tools for the auto parts industry. Achieve high-speed cutting, greatly improve production efficiency, and

ensure high surface finish and long tool life.

The specific processing plan is as follows:

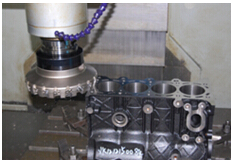

1. Engine block

(1) Milling process: Using the BN-S300 grade of Halnn CBN tool, the productivity is significantly improved, the cutting

performance is stable, and it can replace the international first-line brand such as Seco Tools.

(2) Boring process: Recommended BN-S300&BNK30CBN grade inserts, high cost performance, stable cutting performance, one

of the representatives of engine industry in China.

(3) Chamfering process: customized according to customer needs, the advantage is stable cutting performance and high

cost performance.

The milling cases are as follows:

Compare results

|

|

Processing material: gray cast iron

Processing: Finishing

Tool type: BN-S300 SNEN090308ENS

|

Tool material

|

Feed rate(Fr)

mm/min

|

Single edge life

pcs/edge

|

Cutting fluid

|

|

Halnn BN-S300 |

3670 |

85 |

No

|

A European brand CBN tool

|

3670 |

80 |

No |

2, Engine cylinder head

(1) Finishing process: It is recommended to use BN-S300 CBN grade inserts(solid CBN inserts), which has significantly improved

productivity and stable cutting performance. It can replace the international first-line brands such as Seco Tools.

(2) Valve chamfering process: customized according to customer needs, the advantage is stable cutting performance and high cost

performance.

(3) Matching valve seat turning process: DCGW11T304 is recommended for common models. The advantage lies in high-speed

cutting and high finish.

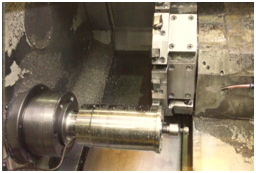

3, Boron cast iron cylinder liner

(1) External turning process: It is recommended that the solid CBN tool BN-S300 CBN grade inserts can be dry-cut, and its tool

durability is N times higher than that of ceramic tools.

(2) Grooving process: customized according to customer requirements for longer tool life and higher production efficiency.

The cases of external turning are as follows:

Compare results

|

|

Processing: Finishing the outer circle

Workpiece material: Boron cast iron

Tool type: BN-S300 SNMN120412

Cutting parameters:

Cutting Speed(Vc)=850m/min,

Feed rate(Fr)=0.25mm/r,

Cutting Depth(ap)=0.5mm

Processing method: wet cutting

|

Tool material

|

Cutting Speed(Vc) m/min |

Processing beat

s/pcs

|

Single edge life

pcs/edge

|

|

Halnn BN-S300 |

850 |

23 |

120 |

A European brand CBN tool

|

500 |

40 |

25 |