Nowadays, no other material today machine abrasive, nonferrous materials will be better than polycrystalline diamond. PCD Cutting Tools will cost about 10 times more than carbide tools. However the payback will be 100 times more than tungsten carbide inserts. Also have other benefits including reduce operator job, increase the production rates, improve the surface finish quality.

The high hardness of PCD also make it have good abrasion resistance, nearly 100 times that of tungsten carbide insert. PCD is the best choice that used in non-ferrous metal, composites and other difficult to machine materials. Excellent results are achieved when using pcd to machine the following materials: silicon aluminum, metal matrix, graphite, composites and other plastics.

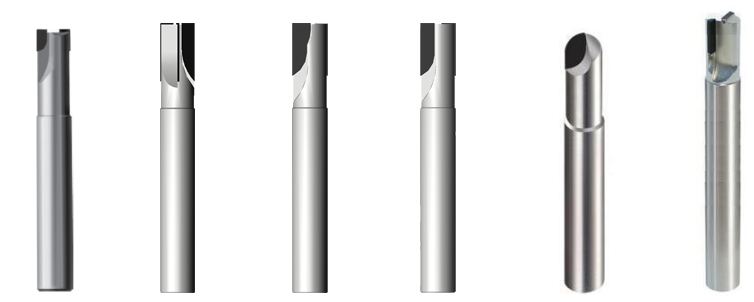

And most application not only use iso pcd insert, but also pcd end mills. The following is some different type pcd end mills:

We also have specification details for your reference, if you are instered in pcd end mills, please feel free to contact with us info@halnntools.com