Advantages of Halnn PCBN Insert hard turning hardened steel

Part 1 Some problems that will meet when hard turning hardened steel

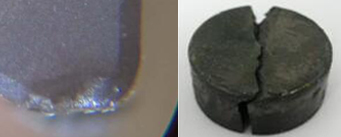

Hardened Steel usually belong to High carbon steel, high alloy steel, the hardness will be about HRC45~68 after heat treatment, is difficult to machine. Hard Turning instead of Grinding need the coordination of the cutting tools and the machine tool with stable performance and good gridity. Especially when meet interrupt turning condition, the workpiece and the component will be impacted continuously, the cutting tools will be easily chipping or brake, which will lead to low efficiency, even damage the component.

Part 2 The cutting tools choice for hard turning replace grinding

Choose the right cutting tool is one of the main factors to make sure high efficiency when hard turning hardened steel. Based on the characteristics of hardened steel, hard turning inserts need have enough strength, toughness, hardness and abrasive resistance, it proved that PCBN Insert is the ideal cutting tools for hard turning hardened steel in current times, especially the chipbreaker cbn inserts, wiper cbn inserts and coating pcbn inserts, a series of PCBN Inserts with new design make cbn inserts used widely in more industries. In current times, Halnn have a series solutions of hard turning inserts from continuous turning to interrupt turning, from roughing to finishing process.

For continuous turning hardened steel with Halnn PCBN Insert: We recommend BN-H10 PCBN Insert, the roughness can reach Ra0.4, and we also can offer coating pcbn insert BN-H10 C25, which will extand the tool life with the same roughness.

For interrupt turning hardened steel with Halnn PCBN Insert: Because the component and the insert are impacted continuously, we need to choose the pcbn insert with good impact resistance, we recomment BN-H21 PCBN Insert, not only can obey strong impact resistance, but also can make sure long tool life. If choosing wiper cbn insert, the tool life will extand about 1 more times.

For rough turning hardened steel: Because of large cutting allowance, we need to choose the PCBN Insert with high strength and good impact resistance, the best cbn insert grade will be Halnn BN-S20, which can cut about 7mm deep for hardened steel component which hardness is above HRC45.

Part 3 Halnn CBN Grade for hard turning hardened steel

|

CBN Grade |

Binder |

CBN Content

(%) |

Granularity (μm) |

Depth of Cut (mm) |

Cutting Condition |

|

BN-S20 |

TIN |

76 |

4-6 |

1-10mm |

Interrupt- Continuous |

|

BN-H20 |

TIC |

80 |

2-4 |

≤ 1mm |

Semi-Interrupt Turning |

|

BN-S200 |

TIN |

60 |

2-4 |

≤ 1mm |

Continuous Turning |

|

BN-H11 |

TIN |

70 |

2-4 |

≤ 1mm |

Continuous |

|

BN-H10 |

TIN |

50 |

≤ 1 |

≤ 0.5mm |

Continuou-Light Interrupt |

|

BN-H21 |

AL,TINC |

60 |

1-2 |

≤ 0.5mm |

Heavy Interrupt turning |

When you need to know more information on hard turning hardened steel, please feel free to contact with us info@halnntools.com