BNK30---new CBN material for High-speed cutting brake discs

Brake discs, as the main components to ensure the safety of the car, not only require high on the product quality, but also has high requirement on processing efficiency with the development of the automotive industry. So high-speed cutting has become a processing technology required by modern manufacturing industry. And to achieve high-speed cutting brake discs need to cooperate with the cutting tools. The cutting tools, as the tool machining the brake disc, the performance has a direct effect on the surface quality of the brake disc and the production efficiency.

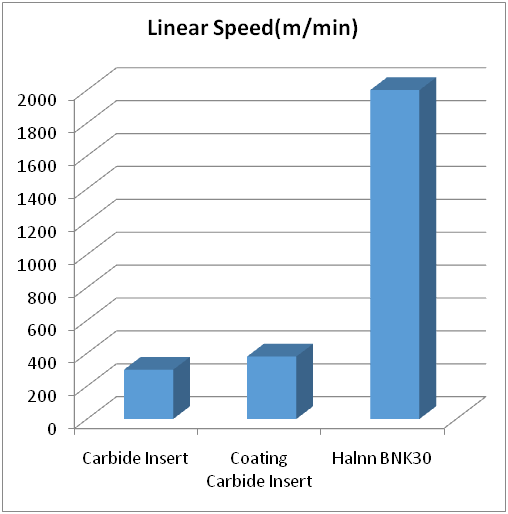

Specific for this situation, Halnn developed a new kind material--- BNK30 grade for machining brake disc, which is made of nano-grade cubic boron nitride grain and binder, and can be used for high speed cutting brake disc with 500~2000 m/min. They can make sure the the stable performance. Especially in the finishing process, comparing with the carbide insert and coating carbide insert, the tool life is improved several times.

The data details as following chart

(1) The Linear Speed of Halnn BNK30 can be 6 times more than carbide insert

(2) The Tool LIfe of Halnn BNK30 can be 30~50 times more than carbide insert.

We can see that, Halnn BNK30 cbn insert materials can be used for high speed machining, and the tool life will be about 30~50 times than carbide insert, it will be the most suitable cutting tools for machining gray cast iron parts. It will be more economic.