Halnn tools, as a pioneer in the localization of super-hard tools in China, has a market share of more than 60% in the CBN tool segmentation field, such as cast iron finishing/high-speed steel rolls/bearing hard turning. From 2020 with advantages and technical reserves, we have exerted great efforts on diamond cutting tools and achieved certain results. This time Halnn tools bring you as following Halnn’s three characteristic products in the diamond fields.

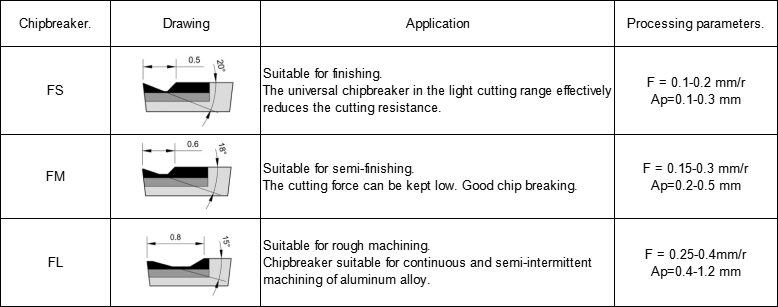

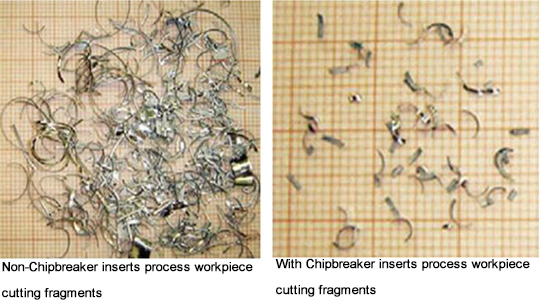

Characteristic product 1: PCD chip-breaker inserts

Halnn PCD inserts not only increase cutting speed exponentially, but also Improvement of chip condition and improved the processing quality by adding chip breakers. At the same time, it escorted the identification and automatic grabbing of parts in the automated and intelligent production line.

Characteristic product 2: Aluminum-based silicon carbide and other MMC materials milling tools

Characteristic product 2: Aluminum-based silicon carbide and other MMC materials milling tools

Aluminum-based silicon carbide and other MMC composite materials are currently widely used in aerospace, military and other fields as a modern new composite material. The density is 1/3 of steel, but the strength is higher than that of pure aluminum and medium carbon steel and high wear resistance. but at same time also very difficult to process, such as tool wear fast, high production cost, low processing efficiency, etc. Halnn tools technical team has undergone repeated testing and practice, at present, the PCD tool made of CDW010 has achieved stable development in the aluminum-based silicon carbide milling and drilling process, and the PCD milling tools Halnn has basically realized the stocking of semi-finished products, which greatly shortens the delivery cycle. The following is an application case of Halnn PCD milling tools in satellite parts (because the processed parts are confidential parts, They are not allowed to be shown here)

Processing method: milling processing

Tool used: D4 PCD end mill

Machine tool: Beijing Seiki

Processing part: step cleaning

Application field: satellite parts

Effect of use: The service life of a single cutting edge is 4 hours, which is 12 times the service life of a carbide milling tools and 1.5 times the service life of a domestic brand PCD milling tools.

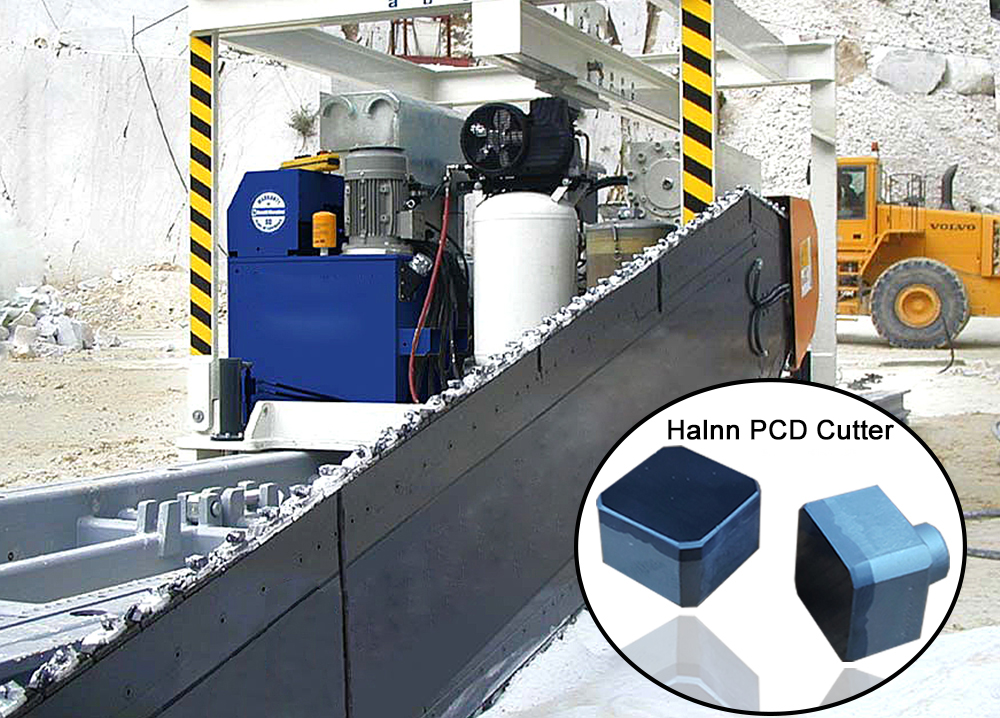

Characteristic product 3: PDC chain saw inserts

As you know, PDC (polycrystalline diamond compact) , the widely known application field is the drilling tool used to directly break the rock at the bottom of the hole in engineering drilling. and another area is PDC chain saw inserts for marble mining.

Marble is a non-renewable resource. In order to better preserve the integrity of the marble and increase the block rate during mining, more companies choose chain saws instead of wire saws to cut marbles. The chain saw inserts equipped on the chain saw are PDC composite inserts, and a piece of equipment needs to be matched with dozens to more than 100 inserts.

Halnn tools PCD chain saw inserts have excellent comprehensive properties such as high strength, high wear resistance, high impact toughness, high thermal stability, etc., and will not break abnormally. At present, they have formed semi-standardized and exported to many foreign countries on a large scale, becoming Halnn tools single export champion.