Halnn PCBN Inserts Hard Turning of Ball Cage Universal Joint

Cage, also called "CV joint",

Cage, also called "CV joint", is an important part of the car's transmission system. Its function is to transfer the power of the engine from the transmission to the driving wheels to drive the car at high speed.

There are many types of CV joints used in cars, among which the most widely used are the ball cage type CV joint and the tripod type CV joint, mainly including sliding sleeves, three-way shafts, drive shafts, and star sleeves. , The main parts of the cage and the bell-shaped shell.

Outer ball cage: The steel balls of this ball cage are fixedly placed in the six windows of a cage between the star sleeve and the bell shell. The steel balls in the star sleeve and the bell shell have exactly half each To determine the angle of action with the universal joint at one time, the smooth surface treatment makes the universal joint move like a helical gear. The six steel balls push the respective star sleeve and the ball path in the bell shell. It's just that the torque is transmitted through the steel balls instead of the teeth of the gears.

Inner ball cage (three-pronged type)

Inner ball cage (three-pronged type): There is no steel ball inside the three-ball pin type CV joint, but three bearings with needle rollers are used, which can slide in the three tracks in the bell-shaped shell. It is mainly used for the inner ball cage of four-wheel drive vehicles. It is suitable for the position of the inner ball cage with a small torsion angle. It can slide inward and outward to adapt to the change in length of the drive shaft when the vehicle is moving.

Inner ball cage (six-ball type): This type of sliding CV joint product has a different design concept. The steel ball in the inclined track transmits the torque. The performance of the product is excellent, and it exceeds the TJ type. The ball cage, but the sliding distance is shorter, can solve the noise problem, and is widely used in four-wheel drive vehicles.

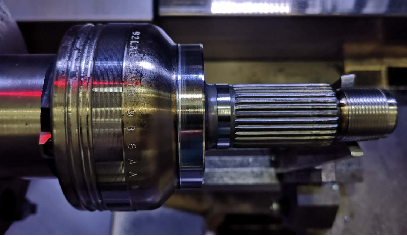

Case of Hard turning outer diameter of ball cage

Processing part: outer diameter of outer ball cage (total three parts)

Processing size: ø31.445, ø68, ø87.1

Workpiece material: Hardness steel

Workpiece hardness: HRC58-63

Processing procedure: finishing

Model: BN-H10 C25 (4165) CNGA120408S0015-4S (adding a Wipert)

Processing parameters:

ø31.445 Vc=140m/min,S=1447 ,Fr=0.35

ø68 Vc=172m/min,S=843, Fr=0.35

ø87.1 Vc=146m/min , S=534, Fr=0.45

After testing the wiper inserts, the finish at the outer diameter of ø68 is within Ra0.8.

Without wiper inserts Fr=0.1-0.15. With a wiper inserts, the Fr can reach 0.35-0.45. Under the premise of ensuring the roughness, the processing efficiency is 3 times that of without a wiper inserts.