With the development regular of metallurgical steel industry, the customer’s requires is higher and higher for the rolls materials and processing speed. The Wc/Tc rings, one of the most hard metal rolls, were widely applied high speed threaded rolling mill, of which processing speed usually gets above 75m/s and the highest speed gets 120~140m/s.

Cemented carbide (tungsten carbide) roll ring has high hardness, which beyond the hardness of traditional cutting inserts. The milling or turning Tc rolls rings mainly about adopt the superhard inserts, such as CBN inserts and the Diamond cutting.

Tc rolls or mill rolls’ rings processing order divides into turning and milling. Now we will introduce two respects them.

The choice of turning Tc rolls and roll rings. Now many factories adopt grading finished product to replaced turning arts, but Very few choices of turning technology

When the hardness

When the hardness >HRA88, the manufacture can choose the diamond inserts. The higher the hardness of the workpiece, the more brittle the material is. Therefore, be careful to avoid collapse inserts when turning the hard alloy (tungsten carbide) roller ring. We need to do chamfering in advance and accurately reserve the finishing allowance.

At the same time, the cutting edge form of the turning insert is based on the hardness of the hard alloy (tungsten carbide) roll ring, the rigidity of the machine inserts and the past experience of user. The cutting edge form of the CBN insert is often E (passivated), S02020 (chamfered + Passivation is the mainstay, and the PCD tool cutting edge is often dominated by F (edge).

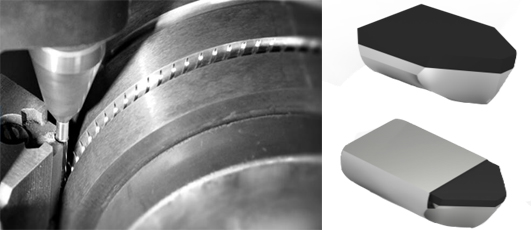

Tool selection for milling tungsten carbide roll/roll ring: Milling tungsten carbide roll/roll ring is mainly to milling crescent groove, also known as rib cutting. The milling process mainly uses PCD rotary milling cutter with rotary cutting tool arbor (1 tool arbor with 2 milling cutters, after which the rotary cutting tool arbor needs to be replaced).

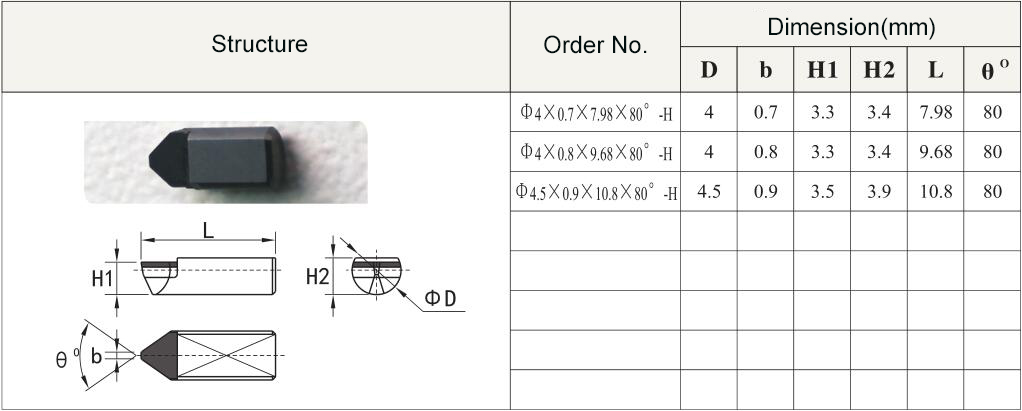

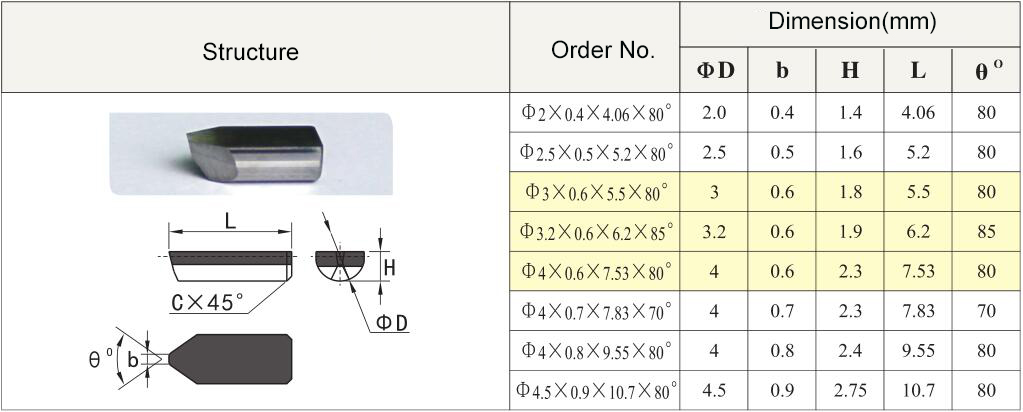

PCD rotary milling cutter can be used in both new roll making and repairing rolls. PCD rotary milling cutter has two kinds of structure choices: welding and full face. Welding structure is chosen for the diameter of 4mm or more (the maximum is 9mm). Full face is mainly used for the diameter of 4mm or less.

The cutting speed range of PCD rotary milling cutter for threaded steel is: Fr = 0.05-0.10; N = 180r/min (the rotational speed of different rolls is different)

There is the centralized specifications of PCD rib cutter and PCD welding rib cutter, which can also be customized without standard.