1.Types and Development of Ceramic Tools

The development of ceramic Tools can be summarized as the toughness of the Tools is gradually enhanced: AI2O3 Ceramic Tools - composite AI2O3 Ceramic Tools - SI3N4 Ceramic Tools - Cubic Boron Nitride Tools.

In the field of metal cutting tools, AI2O3 Ceramic Tools and SI3N4 Ceramic Tools are collectively referred to as ceramic Tools; In the field of inorganic non-metallic materials science, cubic boron nitride materials belong to ceramic materials, and the advent of cubic boron nitride material tools is the revolution of ceramic tools. Halnn Superhard is one of the earliest research institutes in China to study polycrystalline cubic boron nitride materials. Recently, the pure boron nitride sintered ceramic insert has been introduced, which has significantly increased toughness and wear resistance.

2. Performance Comparison between Ceramic Inserts and CBN Inserts

Compared to cemented carbide inserts, ceramic inserts can withstand temperatures up to 2000 ° C, while carbide inserts soften at 800 ° C. Therefore, the ceramic Inserts has high temperature chemical stability and can be high speed Cutting , but its disadvantage is that the AI2O3 ceramic Inserts has low strength and toughness with is easily broken.

The hardness of cubic boron nitride inserts is higher than ceramic tools. CBN inserts and PCD Tools are called superhard materials. Although the cubic boron nitride insert is more brittle than the cemented carbide insert,But it has better impact strength and crush resistance than the ceramic insert.

Halnn Superhard BN-K1, BN-S300 grade Solid sintered cubic boron nitride inserts can Machining large allowance and high hardness materials, especially in the field of heavy interrupted cutting.

Although cubic boron nitride is classified as ceramics in materials science,but the toughness and hardness of ceramic Inserts are generally lower than cubic boron nitride Inserts due to the differences in properties of CBN, SIN, Al2O3 and SiN. In the 21st century, CBN tools have gradually replaced ceramic Inserts in some fields.

3.Application Comparison of CBN Inserts and Ceramic Inserts

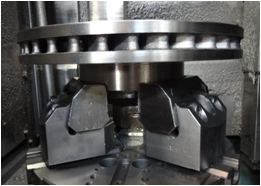

1)CNMX1207 CBN Inserts Machining Brake Disc

|

Item |

Machining Brake Disc

|

Image

|

|

Component Materials

|

GC250 (HT250)

|

|

|

Machining Conditions

|

Semi-finishing, Dry Cutting

|

|

Hardness

|

HB210

|

|

Selected insert

|

BN-S300 CNMX120716(Positioning hole)

|

|

Testing Performance Comparison

|

|

Insert Materials

|

Cutting Parameters

|

CBN Inserts Image

|

|

Halnn BN-S300

|

Vc=800,Fr=0.45,ap=2mm

|

|

Halnn CBN inserts are 6 times longer Life and more efficient than ceramic inserts.

2)BN-K1 CNMN120712 Turning Slurry Pump Body

|

BN-K1 Turning Slurry Pump Body

|

|

|

Workpiece

|

Slurry Pump Body

|

|

Materials

|

High Chromium Cast Iron Cr26

|

|

Hardness

|

HRC60

|

|

Selected Insert

|

BN-K1 CNMN120712

|

|

Cutting Condition

|

Ap=2.5mm, Fr=0.12mm/r,Vc=75m/min

|

|

Insert Materials

|

Lifetime/Tools

|

Failure Mode

|

|

Halnn BN-K1

|

85 pieces

|

Normal Wear

|

|

Ceramic Inserts

|

4pieces

|

Damage Rupture

|

3)RNMN200800 CBN Inserts Machining High Nickel Chromium Alloy

Halnn Solid CBN insert can cut the large amount of material and improve production efficiency. At the same time, the cutting performance is stable and cost-effective.

|

Solid CBN Inserts Machining High Nickel Chromium Alloy Rolls

|

|

|

Workpiece

|

Mills Rolls

|

|

Materials

|

High Nickel Chromium Alloy Cast Iron

|

|

Hardness

|

HSD80

|

|

Selected Insert

|

BN-K1 RNMN200800

|

|

Cutting Parameters

|

Ap=4mm,Fr=0.7mm/r,Vc=45m/min

|

|

Cutting Method

|

Dry Cutting

|

|

Insert Materials

|

Tools Lifetime/Tip

|

Failure Mode

|

|

Halnn BN-K1

|

3 pieces

|

Normal Wear

|

|

Ceramic Inserts

|

Low 1 piece

|

Damage Rupture

|

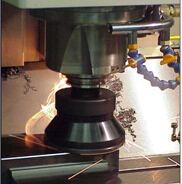

4) Halnn CBN Hard Milling Tools

With Halnn Solid CBN insert, the Tools life is longer than the Ceramic insert, and the cost of the single CBN Tips is lower than the Ceramic insert.

|

Halnn CBN Hard Milling Tools

|

|

|

Workpiece Materials

|

Cr12MoV

|

|

Hardness

|

HRC62

|

|

Selected Insert

|

BN-S200 RNGN090300

|

|

Cutting Parameters

|

Ap=4mm,Fr=0.7mm/r,Vc=45m/min

|

|

Machining method

|

Dry machining

|

|

Insert Materials

|

Cutting speed

|

Tools Lifetime/Tip

|

|

Halnn BN-S200

|

130m/min

|

120 pieces

|

|

Ceramic Inserts

|

90m/min

|

10 pieces

|

More: