The introduction of slot cutter in the filed of high speed steel rolls

High speed steel rolls divided into two hole machining, including the new rolls and repaired rolls. Now introducing them.

For new mill rolls grooving: Due to the large machining allowance and large contact area, the inserts life is short and the efficiency is low. Therefore, the PCBN Inserts can directly process the rolls and improve the machining efficiency. Halnn superhard recommended PCBN inserts BN-S300 grade or BN-S20 grade, meanwhile, using RCMX-V series or RCMX-Y series

For repaired rolls grooving: Due to the hardening phenomenon in the process of machining high speed steel roll, especially the ribbed steel’s processing is more difficult. For the round steel finished roll, it can be processed by the PCBN insert BN-S300 Grade. if there is broken or drop in the groove part, The BN-S20 material should be selected. For the ribbed steel repairing roller, it belongs to interrupted cutting which can adopt the solid PCBN inserts to processing the rolls and no collapse.

The choice of cutting parameter mainly depend on the processing efficiency and the fact machining result. The high speed steel hole machining has many influence for the quality, Productivity, the cost and so on.The spindle speed is a important factor for the surface quality of machining rolls. The higher spindle speed can easy to get the better surface quality.

|

Processing procedure

|

Cutting speed(Vc)

|

Feed fate (Fr)

|

Cutting depth(Ap)

|

|

Roughing

|

50-150m/min

|

0.1-0.5mm/r

|

1-10mm

|

|

Finishing

|

90-250m/min

|

0.05-0.35mm/r

|

≤1mm

|

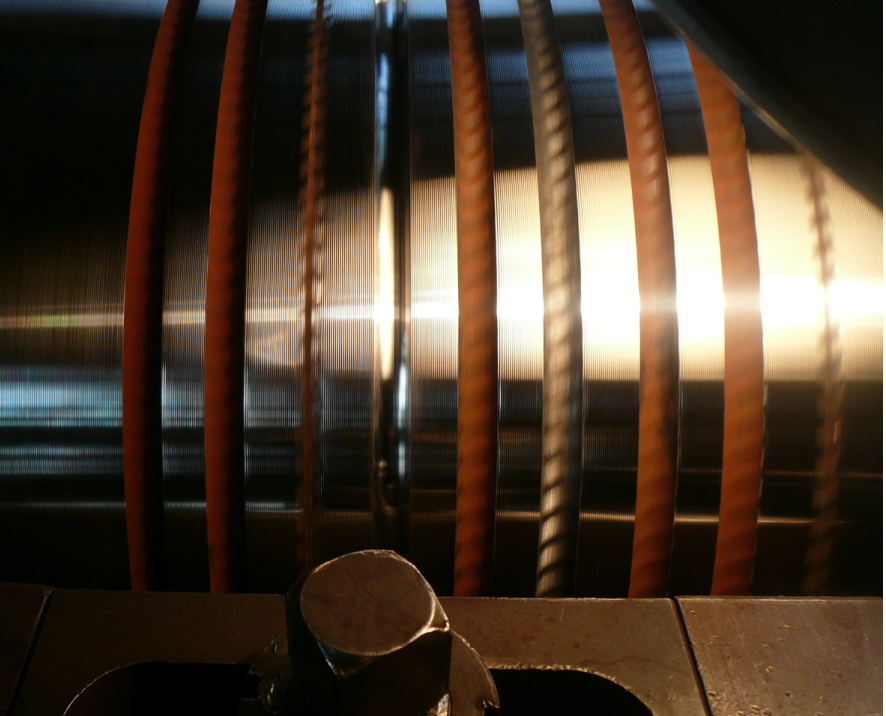

The grooving of high speed steel live picture

|

The New Roll

|

The Repaired Roll

|

The Repaired Roll

|

|

|

|

|

The Application of High Speed Steel Grooving

(1)The application of Repaired the Threaded steel groove

|

Repaired the Threaded Steel Groove

|

|

|

Materials

|

High speed steel

|

|

Hardness

|

HRC64

|

|

Inserts Materials

|

BN-S300

|

|

Cutting Parameter

|

Vc=40m/min,ap=0.5m,fr=0.5mm/r

|

|

Processing affection

|

The Efficiency is 5 times that of some brand inserts and its durability is that of 4 times

|

(2) The application of wire rolls groove

|

The Application of Wire Rolls Groove |

|

|

Processing materials

|

High speed steel

|

|

Hardness

|

HRC63

|

|

Selected inserts

|

BN-S300

|

|

Cutting Parameter

|

Vc=26m/min,ap=2mm,fr=0.5mm/r

|

|

Durability

|

60min

|