The advantage of Wc/Tc mill rolls

The Wc/Tc is a hard material. The rolling speed can get above 75m/s and its best rolling speed can get 120-140m/s, because the hardness of wc/tc rolls can get HRA78-95 under the normal temperature, which is very suited for the development of steel industries in modern.

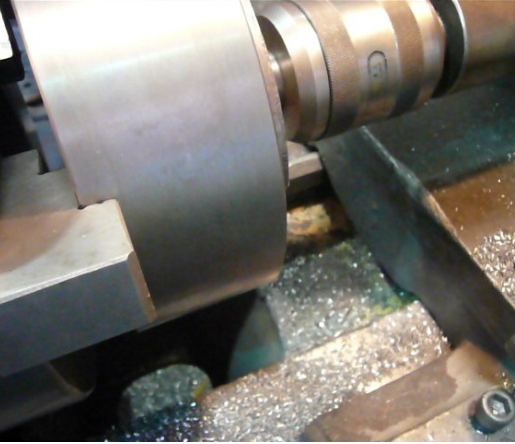

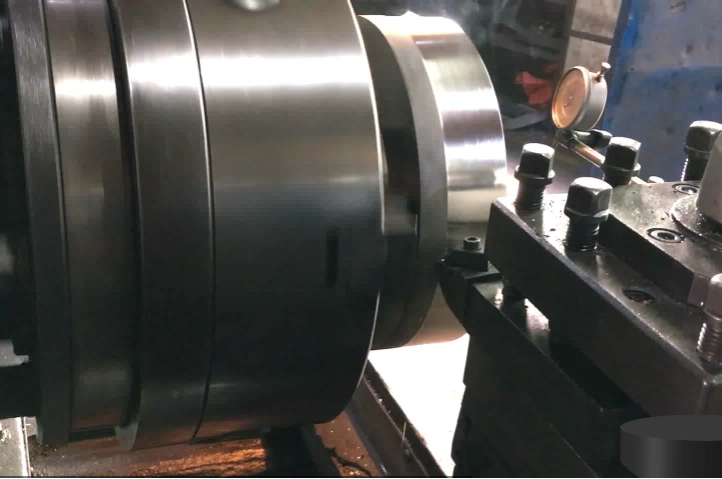

At the same time, the rolls producers adopt Cryogenic and pressurized sintering to making the Tc rolls that no sand holes. The service life and wear resistance are guaranteed. The rolls producers adopt the CNC to process it and promises the better quality

The selected inserts of processing Wc/Tc rolls

The hardness of TC can get HRA78-95 under the normal temperature. The traditional inserts can’t process it. Now the processing arts mainly about grinding. Some parts adopt the turning

We consider the inserts materials and standard chamfer when turning the Wc/Tc rolls. The Wc/Tc rolls hardness is very high, so the inserts easily collapse to lead the workpiece breaken. Halnn recommend CBN inserts and diamond inserts. If the hardness of Tc rolls less than the HRA88 , we recommend the CBN Inserts BN-S300. If the hardeness of Tc rolls less than the HRA88 , we recommend the diamond inserts CDW025 .

The cutting paramater of processing Tc rolls

|

Workpiece

|

Selected inserts

|

Cutting speed

|

Cutting depth

|

Feed rate

|

|

Tc rolls

|

CBN Inserts

|

Vc≤35m/min

|

ap≤0.8mm

|

Fr=0.25-1mm/r

|

|

Diamond insertsCDW025

|

Vc≤15m/min

|

Ap=1mm

|

0.1-0.2mm/r

0.05-0.1mm/r

|

Processing the Tc rolls: cutting speed Vc≤35m/min, ap≤0.8mm, Fr=0.25-1mm/r(choose the maximum according to the shape of inserts and machining roughness);if the producer adopt the diamond inserts, the cutting depth can get less than number.

The inserts may be passivated when processing the Tc rolls. Passivation treatment is to solve the inserts defected, but the passivation treatment can not be too large, because the inserts edge surface becomes larger after passivation and cutting resistance also increases, carbide rolls and roll rings belong to hard and brittle materials are easy to lead inserts collapse and damage the workpiece.

According to the hardness of rolls and the stiffness of machine tools, it is generally designated by users according to past experience. In the case of CBN inserts, the inserts form is generally chosen as passivation (code "E") and chamfering and passivation (S02020 is the most common one). When cutting TC rolls with diamond inserts. The form of code "F".

The case parameter of Tc rolls with CBN inserts

(1)the case parameter of processing Tc rolls rings (HRA88): Adopt BN-S300 grade, cutting parameter:Vc=15m/min,ap=1mm,Fr=0.3mm/r

(2)the case parameter of processing Tc rolls rings (HRA88): Adopt BN-S300 RNGN120400E, cutting parameter: Vc=20m/min,ap=0.5mm,Fr=1mm/r