Finish turning Ductile Iron Punch Die: CBN BN-K20

Category:News

PublishedDate:2019-06-12

Information

The punch die’s accuracy largely depends on the accurate of work pieces. In order to get a good life, the manufacture usually adopts the heat treatment to improve the accuracy in the machining process.The basic information of the punch die is as following .

Named: Punch Die

Materials: Ductile iron

Heat treatment method: isothermal quenching

Processing procedure: finish turning

Hardness: HRC56

Process site: Outer circle

Diameter: 400mm, length 350mm, inner hole 300mm

Inserts materials information

The Punch Die components hardness get HRC56 after the heat treatment which belongs to the High Hardness and Machine Materials. It isn’t suitable for process the traditional inserts such as high alloy cutter. High alloy cutter processes work pieces that easily appear problems such as no wear resistance or car immovability, and the surface quality of the punch die are required to be high, and the surface quality of the work piece can not be guaranteed.

Ceramic cutting tool was studied three categories:Alumina, Silicon Nitrite and Boron Nitrite.Boron Nitrite was named super hard inserts in the filed of metal, but boron nitrite belongs to the ceramic materials in inorganic nonmetallic materials science.above all,Boron nitrite blade in processing can also be called ceramic blade.

Halnn super hard is a manufacturer specializing in the production and development of boron nitrite blades. It has materials about boron nitrite according to different the materials of work pieces. Halnn super hard give some advise to use the BN-K20 about finish turning punch die.

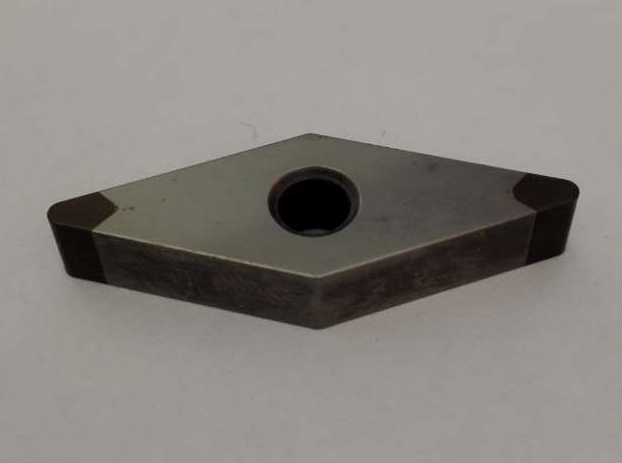

Halnn Super Hard CBN Tool BN-K20 Brand is a through-welded CBN tool specially developed for finishing process.Its advantages are more economical blades, more flexible ways of tightening blades. The BN-K20 types and cutting parameter as following:

Work pieces: BN-K20 VNGA160404-4S

Cutting parameter: spindle speed N=95r/min; feed rate Fr=0.10mm/r; cutting depth Ap=0.20mm