Halnn BN-K1 grade CBN tool for Rough turning Crushing Cone

Category:News

PublishedDate:2019-05-06

Crushing Cone is an important component of the cone crusher. It is mainly used to crush hard and medium hard ore and rock. It

is widely used in mining machinery, metallurgy industry, construction industry, chemical industry and other fields.

In order to ensure the long-term operation of the Crushing Cone, high-manganese steel is often used as the main material of

the Crushing Cone, the hardness and durability are improved. However, the high-manganese steel material Crushing Cone

often has the following difficult processing problems in the processing:

(1) The work hardening of the Crushing Cone is serious, which aggravates the tool wear and is easy to cause the tool to

collapse and damage;

(2) Large cutting force and high cutting temperature, resulting in reduced tool durability and variability of the workpiece,and low

dimensional accuracy;

(3) Due to the high temperature and high pressure between the cutting tools and the chip, it is easy to form built-up edge and

scale,which affects the surface roughness of the workpiece, and it is difficult to ensure the quality of the workpiece;

(4) Chips are not easily curled and broken during cutting, and chip removal is difficult.

In the face of the difficult processing of the above-mentioned Crushing Cone, Halnn Superhard has introduced a material of the

solid CBN tool BN-K1 grade, which has been widely praised by the Crushing Cone industry, Especially in the vertical machining

Crushing Cone. Impact toughness and wear resistance are 2-3 times higher than traditional ceramic tools.

BN-K1 grade solid CBN tool has a cutting depth of more than 7mm, which is more resistant to impact than traditional ceramic tools

and ordinary cutting tools. Especially for the poor processing of casting surfaces, it can be used to rough turning Crushing Cone

without having to polish the workpiece surface.

The tool performance and cutting edge of the BN-K1 grade are developed for the processing characteristics of high-manganese

steel Crushing Cone. They are highly targeted and cannot be used to machine ordinary mild steel parts such as No. 45 mild steel.

The processing cases of Halnn Halnn BN-K1 grade CBN tool rough turning High Manganese Steel Crushing Cone are as follows:

|

Halnn BN-K1 grade CBN tool rough turning High Manganese Steel Crushing Cone |

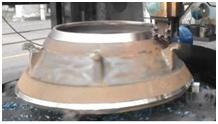

Workpiece picture

|

|

|

Workpiece material |

High Manganese Steel |

|

Tool type |

BN-K1 SNMN150716 |

|

Cutting speed(Vc) |

80 m/min |

|

Cutting depth(ap) |

7.5 mm |

|

Feed rate(Fr) |

0.3 mm/r |

|

processing method |

Dry cutting |

|

Processing effect |

Compared with the traditional carbide tool, the cutting speed is 3.2 times higher than that of the traditional

carbide tool, and the cutting depth is 3 times higher than that of the traditional carbide tool. The production

efficiency is increased by 12 times. |