Introduction of high speed steel materials

High Speed Steel, generally written as HSS, is a tool steel with high hardness, high wear resistance and high heat resistance,

also known as front steel or white steel.Its main application is to make metal machining cutting tools, super-hard material tool

holder base, cold extrusion die and cold pier die, roll and so on. Since the advent of high-speed steel, it has played an important

role in the development of modern industry. When high-speed steel is cut at high speed, even if the temperature reaches 500 °C,

it can maintain high hardness, above HRC60.

Application of high speed steel materials

Typical parts: Since the advent of high-speed steel in 1903, it has been known for manufacturing metal cutting tools. With the

rapid development of science and technology, the application range of high-speed steel has been expanding. Since the 1960s,

Japan has succeeded in testing high-speed steel as a center for the automotive and bicycle industries. About 15% of the high-speed

steel produced today is used to make molds.

Other applications: Semi-high-speed steel, which has appeared in recent years, is a kind of roll material. It has high hardness and

high wear resistance similar to that of high-speed steel, and has excellent red-hardness properties. Therefore, high-speed steel

and semi-high-speed steel are ideal for roll material. The high-speed steel roll is made of high-speed steel with high hardness, high

red hardness, good wear resistance and hardenability as the working layer of the roll, and the forged steel, cast steel or ductile iron

with toughness can meet the requirements as the core material of the roll, and a high performance roll that combines the two in a

metallurgical or packaged manner.

Cutting tool material for machining high speed steel

High-speed steel itself can be used as a cutting tool material. Therefore, to machining workpieces of High-speed steel, it is

necessary to use a tool material with higher hardness than high-speed steel to process. That is the CBN tools. The following

is Halnn CBN tools for machining high-speed steel. The tool materials developed are as follows:

|

CBN grade |

materials |

Processing methods |

Cutting condition |

|

BN-S10 |

High speed steel |

Roughing |

Interrupt cutting |

|

BN-S20 |

Hardened steel, heat-resistant and wear-resistant steel, high manganese steel |

Roughing, semi-finishing |

Interrupt- Continuous cutting |

|

BN-H05 |

Hardened steel, high speed steel |

Finishing |

Continuous cutting |

|

BN-H10 |

Hardened steel, high hardness alloy |

Finishing |

Continuous- Semi-interrupt cutting |

|

BN-H21 |

Hardened steel, high speed steel |

Finishing |

Semi-interrupt –heavy interrupt cutting |

Machining high speed steel case 1

Application of Halnn CBN tool in machining High Speed Steel

|

|

Workpiece material: powder high speed tool steel (M2, M4, M5, M6)

Workpieces Hardness: HRC65-HRC68

|

Difficulties in machining: Originally tried to use an imported brand of CBN tool, the effect is not satisfactory,

mainly in the roughing of the CBN tool life is very short, due to the micro-deformation of the inner hole wall after

vacuum heat treatment, resulting in the situation of chipping in interrupt cutting the CBN tool loss is enormous.

|

Halnn CBN Tool solutions: In view of the customer's trial of a CBN tool for high-speed tool steel with a hardness

of HRC67-HRC65, high-temperature delamination on the upper surface of the CBN tool causes severe wear on

the crater, which can only be processed 1 piece.

|

Finally, try the Halnn BN-H10 grade CBN tool(can withstand interrupted cutting), the cutting effect is very good,

and it is changed to the cutting edge arc of R1.6, and one edge can machining 3-5 workpieces, the customer is satisfied.

|

Machining High speed steel case 2

|

Application of Halnn CBN tool in machining High Speed Steel |

|

Workpieces material: high speed steel of about HRC 67 degrees

Processing sequence: shown on the left

|

Difficulties in processing:

a. Due to the high cutting temperature, the CBN tool current used often

loses the cutting edge, as right.

b. The tool life is too short. At 600 r/m, thefeed rate is 0.02mm, the finish

is quickly deteriorated, the tool change frequency is high,and the

maximum service life of the tool is 37 pieces.The cutting speed was

changed to 1000 r/m,but the tool life was lower. |

|

Tool plan:

1. Redesign of tool structure: Due to the high hardness of high-speed

steel processing, in view of the non-standard groove cutting tools used

by customers, the rigidity is insufficient, and the cutting edge often

chiooing after the tool is heated, so it is changed to the standard

groove cutting tools structure

2. Cutting tool material: Halnn BN-H05 grade CBN tool is selected, due

more resistant to high temperature and high hardness. there is no longer

the case of unstable cutting size and roughness. The customer is very

satisfied with the durability and cost of the tool.

|

|

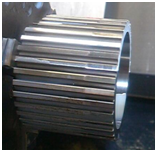

Machining High speed steel case 3

Difficulties in processing:

The hardness is high, the machining allowance is large, the cutting resistance of the grooving is large, and some parts have

interrupt cutting impact, and the cutting tool is easy to chip.

Trial test case:

It adopts Halnn solid CBN tool BN-S20 grade, and its tool life is 2 times that of a brand of CBN tool.

|

Halnn BN-S20 grade CBN tool machining High speed steel rolls |

|

Processing material: high speed steel Roll hardness HSD90 Tool type: BN-S20 RCMX120700 Cutting parameters: Fr=0.2mm/r, Vc=35m/min |

|

Tool material |

Tool life |

Failure modes |

|

Halnn BN-S20 grade CBN tool |

25 Groove/edge ↑ |

Normal wear ★ |

|

A brand of CBN tool |

12 Groove/edge |

Breakage |

Machining High speed steel case 4

Difficulties in processing:

Ultra-high hardness parts, large machining allowance, and severe interrupt cutting conditions, the cutting tool is easy to break

and cannot be processed normally.

Trial test case:

The Halnn brazed CBN tool BN-H21 can withstand strong interrupted cutting without chipping.

|

Halnn BN-H21 grade CBN tool machining high speed steel |

|

Processing conditions: strong interrupt cutting outer circle Workpieces material: high wear-resistant powder high speed steel, HRC65; Tool type: BN-H21 CNGA120408 Cutting parameters: ap=0.15mm, Fr=0.1mm/r, Vc=35-60m/min, wet cutting |

|

Tool material |

Tool life |

Failure modes |

|

Halnn BN-H21 grade CBN tool |

5pcs ↑ |

Normal wear ★ |

|

A Japanese brand PCBN |

<1pcs |

Breakage |