Halnn Diamond PCD Tools For Tungsten Carbide Materials

Category:News

PublishedDate:2018-10-17

Tungsten Carbide is a type alloy material which is made of the hard compound of refractory metal and the bonding metal by powder metallurgy method. In addition to making cutting tools, it can also be used as various wear-resistant and heat resistant parts. The hardness of tungsten carbide is about HRC69~81. As a pioneer of the superhard cutting tools in China, Halnn Diamond cutting tools can replace the ekectruc spark, grinding and other process when machining tungsten carbide tools. Following is some application of Halnn PCD Tools for tungsten carbide materials.

1.Turning Process

Tungsten Carbide belong to one type materials that is difficult to machine, it rely on grinding process in the past times, with the development of the cutting tools technology, pcd tools begin appear in this field.

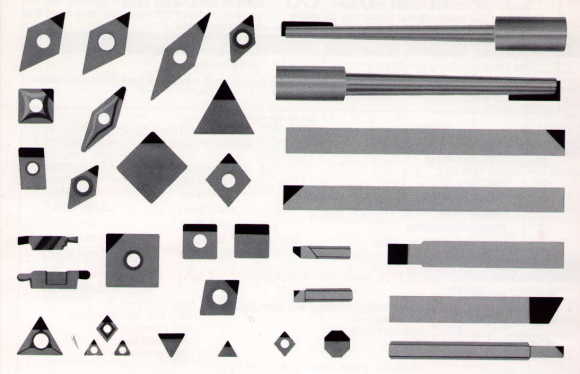

Diamond Tools (PCD Tools) is a polycrystalline material obtained by polymerizing diamond micropowder through metal bond (such as CO) under high temperature and high pressure conditions. It has good flexural strength and toughness, and wear resistance is 140 times that of corundum abrasive. At the same time, the friction coefficient is smaller than other tool materials, and it is suitable for processing hard alloy with hardness above HRC65.

In addition to PCD Tools, we also can use CVD Diamond Coating Tools for tungsten carbide machining,we use low cutting speed and cutting fluid, which also can help obtain Ra100nm surface roughness.

2. Milling Process

Tungsten Carbide Materials are widely used in the tool and die industry due to its excellent durability. Among them, the cemented carbide mold is mainly used for high precision machining, and the surface quality is very high. The diamond milling cutter is the best choice at this time.

For milling tungsten carbide, Halnn usually can offer CVD diamond tools and Brazed PCD Tools depending on the customers’ requirements, which can replace Electrolytic corrosion and sparking process and improve the production efficiency and product quality, such as when milling tungsten carbide, the roughness can reach 0.073 μm at most.

Brazed PCD Tools can be made as PCD end Mills, PCD Ball nose end mills, pcd drill bits, pcd reamers. We brazed PCD on the tungsten carbide holder, which can help improve the surface roughness.