PCD Tools Species and Application

Category:News

PublishedDate:2018-08-08

Part 1 The main advantages of PCD materials

(1) The Hardness can reach 8000HV, is about 80~120 times of the cemented carbide ;

(2) The thermal conductivity is 700W / mk,is about 1.5~9 times that of cemented carbide, even higher than that of PCBN and copper.

(3) The friction coefficient is only 0.1~0.3 (carbide coefficient of friction is about 0.4~1), so PCD tool can significantly reduce the cutting force;

(4) Thermal expansion coefficient is only 0.9×10-6 ~1.18×10-6,only equivalent to 1/5 of carbide, its thermal deformation is small, high machining precision;

(5) The affinity between PCD tool and non-ferrous metals,non-metallic materials is very small, it will easily produce the BUE in the in the process of cutting chips.

Part 2 The Species of PCD Tools

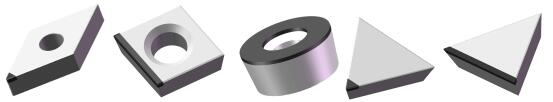

1. PCD Inserts

PCD Inserts include various cutting tools, such as pcd turning inserts, pcd milling inserts, pcd boring tools, pcd grooving inserts, full face pcd inserts and full side pcd inserts, the following is some image.

2. PCD End Mills

PCD End Mills are usually brazed 1 or more pcd tips on tungsten carbide or steel shank, mainly used for milling flat form and some side faces.

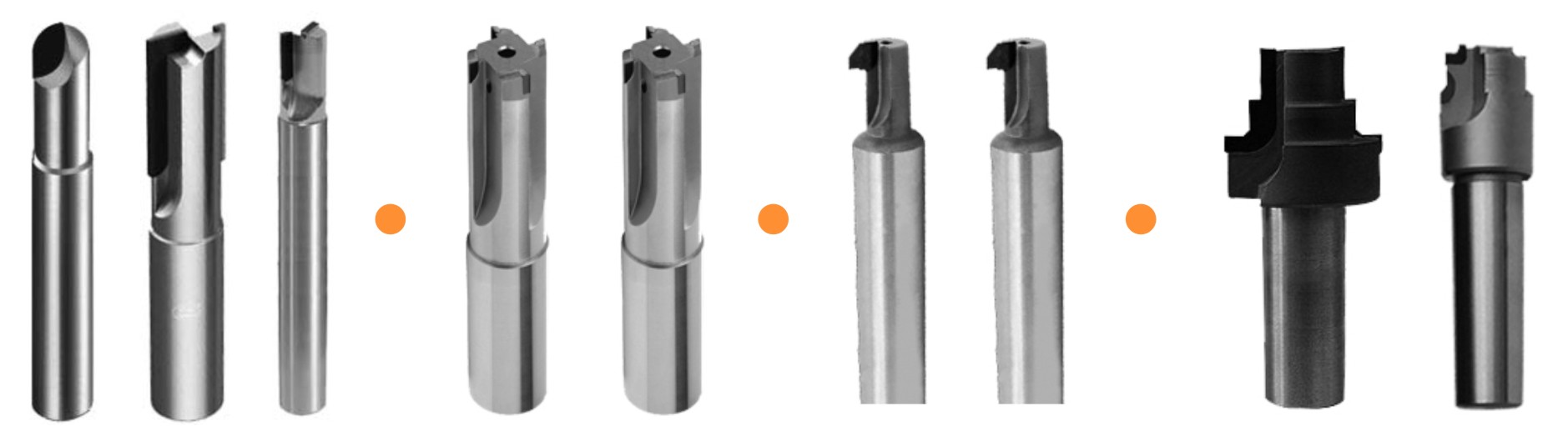

3. PCD Drill or PCD Reamers:

The cutting edges of PCD Drills can be 2 or multi-edges depending on the different diameters. They are usually used for some application which require high precision, tolerance and surface roughness. With Halnn PCD Drills, the roughness can achieve Ra0.1 at most.

4. PCD Boring Tools

PCD Boring Tools are usually used for machining the holes which require high surface roughness and tolerance. For the brazed pcd boring tools, we require the diameter is more than φ3.5.

5. PCD Forming Tools

It belongs to Rotary PCD cutters, can milling many Step holes, which can ensure high efficiency and the high precision.

Part 3 The application of PCD Tools

1. Machining materials

Non-ferrous metal materials and their alloys: such as aluminum alloy, magnesium

aluminum alloy, silicon aluminum alloy, copper alloy, copper, brass, tungsten carbide, ceramics, etc. Above materials can be processed by Halnn PCD Grade CDW010 which belong to the universal materials. For other alloy materials with higher wear resistance, coarse-grained and mixed-grain, PCD tools CDW025 and CDW302 are available.

Non-metallic materials: such as composite materials, carbon fiber, glass fiber, graphite, wood, stone, urethane rubber, glass, reinforced plastic, etc. The PCD inserts CDW002, CDW010, CDW025 and CDW302 are more wear-resistant than alloy blades. Longer life and higher efficiency.

2. Application Industry