About Wiper insert (CBN/PCD/Tungsten Carbide)

Category:News

PublishedDate:2018-06-08

What is the wiper insert?

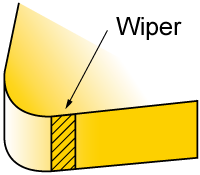

The wiper insert is designed with a wiper edge that is situated where the straight edge meets the corner radius. The dimension is like the image as follows:

The advantages of the wiper insert than common insert without wiper

(1)Improve Surface Finish

With same machining conditions as conventional cutting tools, but with higher feed rate, The wiper insert will improve the the surface finish of the workpiece.

(2)Improve Efficiency

Wiper Insert with High feed rates not only shortened machining times but also make it possible to combine roughing and finishing operations, which will help improve the working efficiency for the manufacturers.

(3)Increased Tool Life

When change to high feed rate, it will cost short time to machine each component, thus one insert can machining more parts. So the tool life on each insert will be increased.

(4)Improve Chip Control

With high feed conditions, the chips generated become thicker and are more easily broken, thus, chips control are improved.

We know that wiper has so many advantages, what is wiper technology?

The wiper technology for turning is based on a series of radius that make up the cutting edge. On a conventional insert, the tip is just one radius. However, the wiper edge is made up of a large, main radius together with several smaller radius. The long wiper edge should not misshape the surface nor generate unacceptable cutting forces. The wiper insert should also be as straight forward to set up and use as an common insert.

In turning with a single-point tool, the surface finish is determined by the feed rate and nose radius, as these are in a direct relationship to the profile height of the surface (Rmax). This means that the higher the feed, the rougher the surface generated by the edge of a given nose radius. Wiper inserts have helped change this through the effect of their specially developed edges that smooth the scalloped tops that would otherwise have been created.

So if you would like to improve the efficiency, decrease the processing time and improve the roughness with a higher rate, the wiper insert can be your good choice. If you would like to know more information about the wiper insert, you can feel free to contact with us info@halnntools.com. We would like to help you with your application.